Laser cutting machine and laser welding machines are widely used in the following industry, such as sheet metal fabrication, metallic job-shops,Elevator industry,Shipyard building industry,Food and drugs machine manufacturing, other machine manufacturing…

This article explores the global landscape of 3D laser cutting machines, comparing the technological advancements and key products from international leaders like Trumpf and Prima Power with developments in China. It analyzes the performance of gantry-type vs. robotic systems and fiber laser vs. CO₂ laser technologies, while forecasting key trends such as higher power, increased speed and precision, and greater intelligence.

In the field of rail transit operation and maintenance, metro wheelsets, as critical components, must have their epoxy resin coating (approximately 150-250 μm thick) completely removed before magnetic particle testing. Traditional chemical paint removal methods suffer from environmental pollution, health hazards to personnel, and low efficiency. To address this problem, DMK has innovatively launched an automated paint removal system based on composite lasers, providing a complete solution for green, efficient, and intelligent wheelset maintenance.

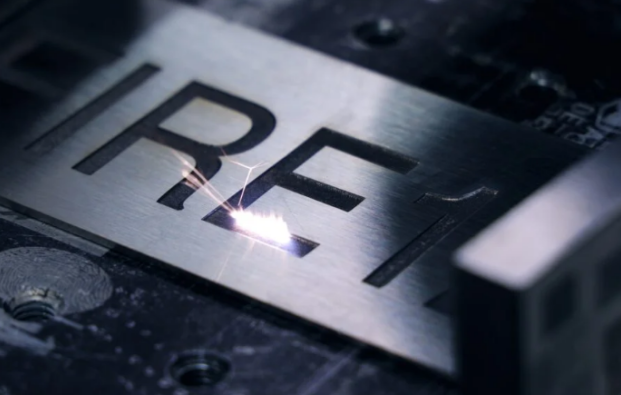

Ⅰ. Technical core and advantagesWith the characteristics of strong directionality, high energy density (up to 105 1015W/cm2), and good spatio-temporal control, laser technology has become the core processing method in aerospace, automobile manufactur...

I. Core Background and Technological Advantages Industry Pain Points: Traditional laser marking relies on tooling fixtures for positioning, resulting in high manual intervention, low efficiency, and high requirements for skilled workers. ...

I. Industry Pain Points of Marine Paint Removal and the Introduction of Laser Technology Ships operate in highly corrosive marine environments for long periods, and their surface coatings serve as a critical barrier against corrosion. However, these ...

Leads the Upgrade of Extra-Thick Plate Processing Thick and extra-thick plates are widely used in engineering machinery, bridges, marine engineering, and heavy structural component manufacturing. Their cutting quality directly affects the structural ...

Amid the wave of industrial cleaning technology iteration, DMK Laser Cleaning has emerged as a "new benchmark for cleaning" in the power and aerospace sectors, leveraging its core technological advantages. This cutting-edge technology, which achieves...

In the marine environment, ship components face persistent challenges such as corrosion and wear year-round. Traditional repair methods either result in excessive deformation or have limited repair thickness, failing to meet the operational requireme...

In the industrial blanking field, the cutting of medium and thick carbon steel plates and stainless steel plates has long relied on traditional technologies such as plasma cutting and flame cutting. However, as manufacturing requirements for precisio...