Laser cutting machine and laser welding machines are widely used in the following industry, such as sheet metal fabrication, metallic job-shops,Elevator industry,Shipyard building industry,Food and drugs machine manufacturing, other machine manufacturing…

The rail locomotive industry robot laser cleaning and derusting machine is a kind of equipment specially used for cleaning and removing the rust on the surface of rail locomotives.

The three-dimensional laser cutting machine for special-shaped materials in the automotive industry is a special equipment for cutting special-shaped materials in the automotive industry.

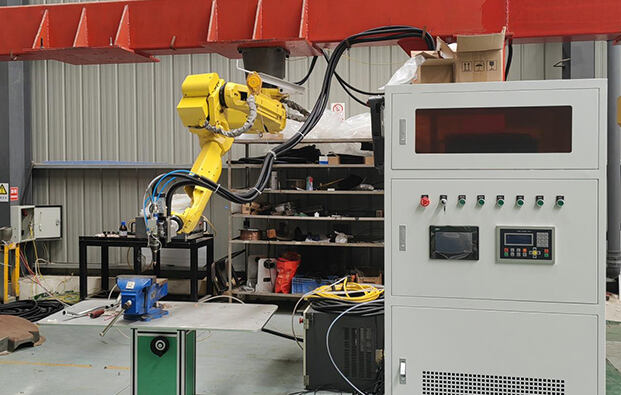

The robot laser welding machine manufactured by our company is composed of Eston six-axis industrial robot, MAX continuous fiber laser, Qilin BWT30 light double pendulum laser welding head and Hanli chiller, etc.

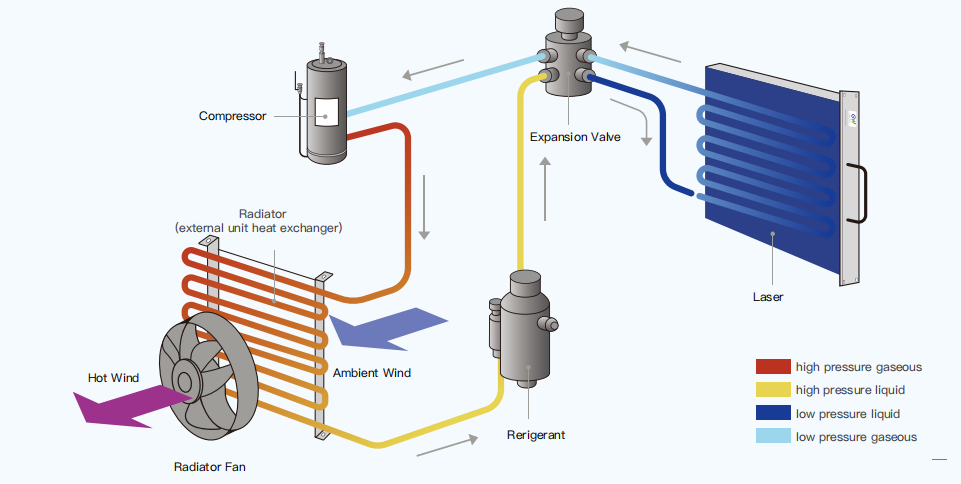

Low temperatures are an "invisible killer" for laser equipment! When the temperature drops below freezing, water in the cooling circuit freezes and expands—at best clogging pipelines, and at worst causing pipe bursts and optical cable damage, l...

Welding is more than just a metal-joining technique; it’s a critical skill supporting core industries like infrastructure, aerospace, and maritime. This field offers numerous specialized career paths—some challenge limits in extreme ...

The high precision of laser welding relies on the precise coordination of every link. Many people focus on the performance of laser equipment but overlook the welding wire—a "core supporting role" that is by no means just a filler metal. Instea...

In fields such as industrial production, cultural relic protection, and equipment remanufacturing, contaminants like rust, oxide scales, and oil stains on metal surfaces directly affect product quality and service life. Traditional cleaning methods s...

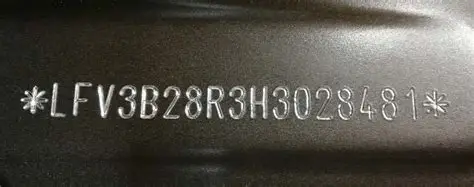

In automotive manufacturing, the VIN (Vehicle Identification Number) serves as the vehicle's "ID card," carrying key functions such as vehicle traceability, quality control, and anti-counterfeiting. According to national standards, the VIN must be en...

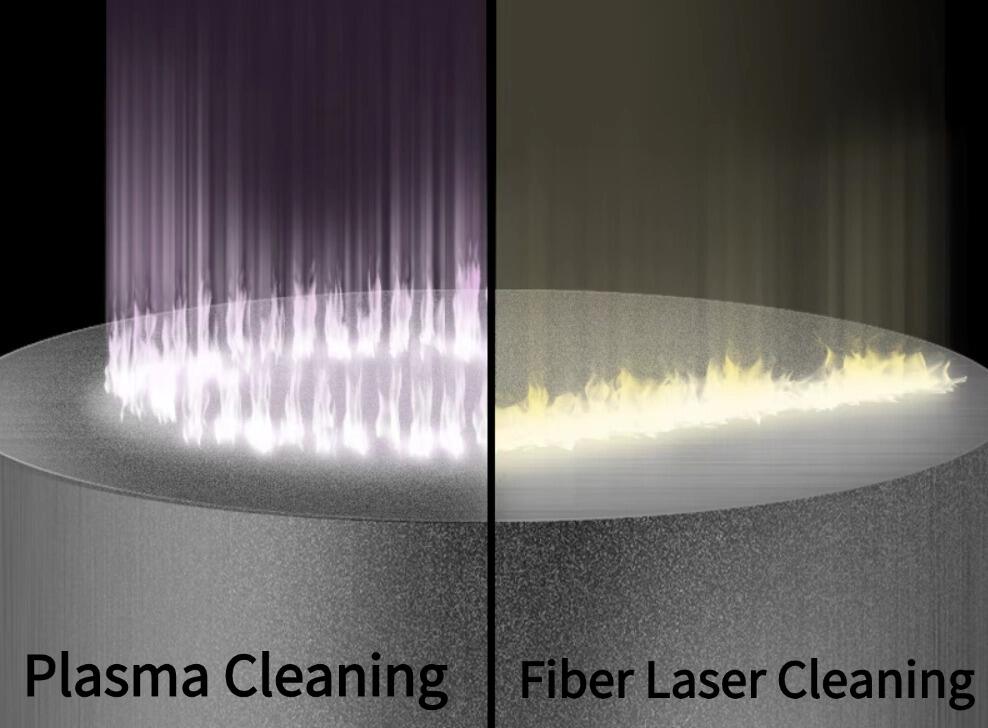

Choosing the right technology for industrial cleaning can save costs and boost efficiency! Both fiber laser cleaning and plasma cleaning are mainstream eco-friendly solutions today, but their applicable scenarios differ greatly— the former exce...