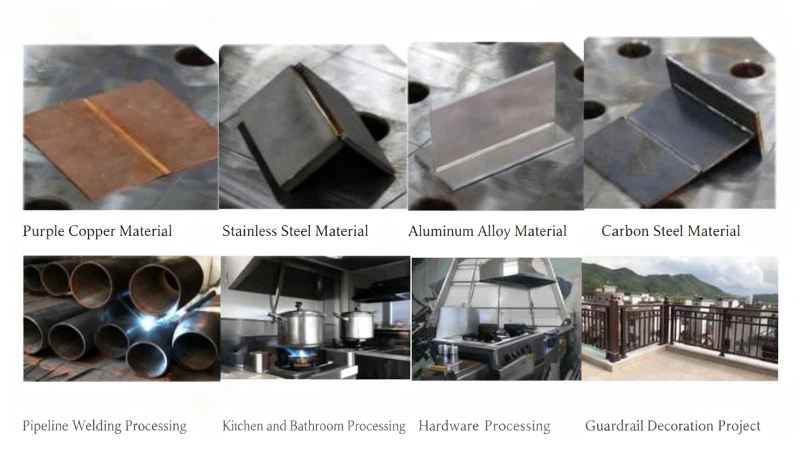

Laser cutting machine and laser welding machines are widely used in the following industry, such as sheet metal fabrication, metallic job-shops,Elevator industry,Shipyard building industry,Food and drugs machine manufacturing, other machine manufacturing…

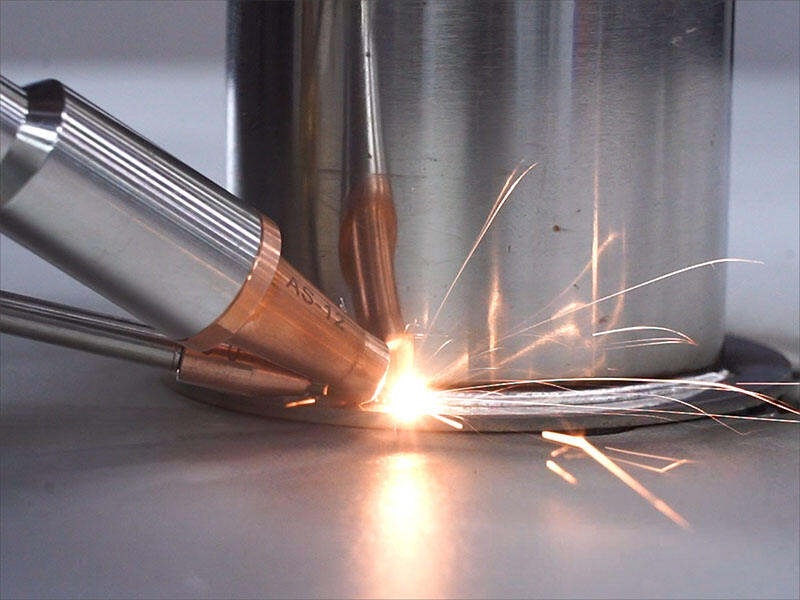

In workshop production, choosing the right welding equipment directly determines productivity, product quality, and business competitiveness. As two core welding technologies, spot welders and laser welders differ significantly in application scenari...

In fields such as metal processing, decorative design, and product traceability, color marking is an important means to convey information and enhance aesthetics. Traditional metal coloring methods like printing and electrochemical treatment have dra...

In industrial fields such as stainless steel processing, nuclear energy equipment, and automobile manufacturing, welding is a core process ensuring the sealing performance and structural strength of components. Traditional welding technologies suffer...

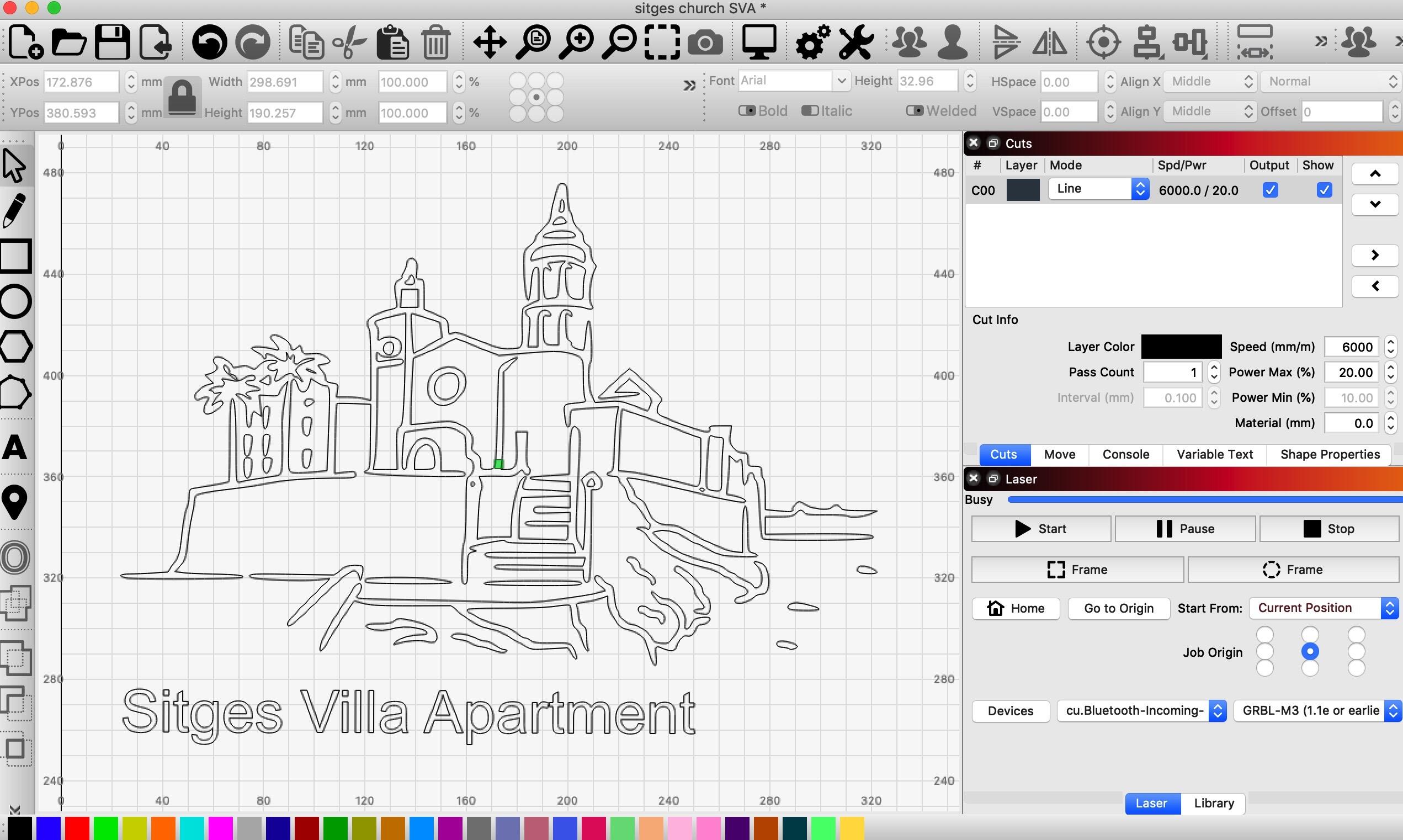

For craftsmen, manufacturers, and business owners, choosing the right glass laser marking machine is key to unlocking the value of glass processing. A suitable device can transform ordinary glass into high-quality products with personalized designs o...

The safety of laser technology in glass marking is a core concern for users. The answer is clear: laser marking on glass is completely safe when using professional equipment and strictly following operational procedures. For professional manufacturer...

With the rapid development of the automotive industry, the remanufacturing of high-value parts from end-of-life vehicles has become a crucial link in resource recycling. As the core component of automobiles, transmissions—especially components ...

In fields such as industrial rust removal, cultural relic restoration, and precision component cleaning, laser cleaning is gradually replacing traditional processes like chemical cleaning and mechanical grinding, thanks to its non-contact, non-damagi...

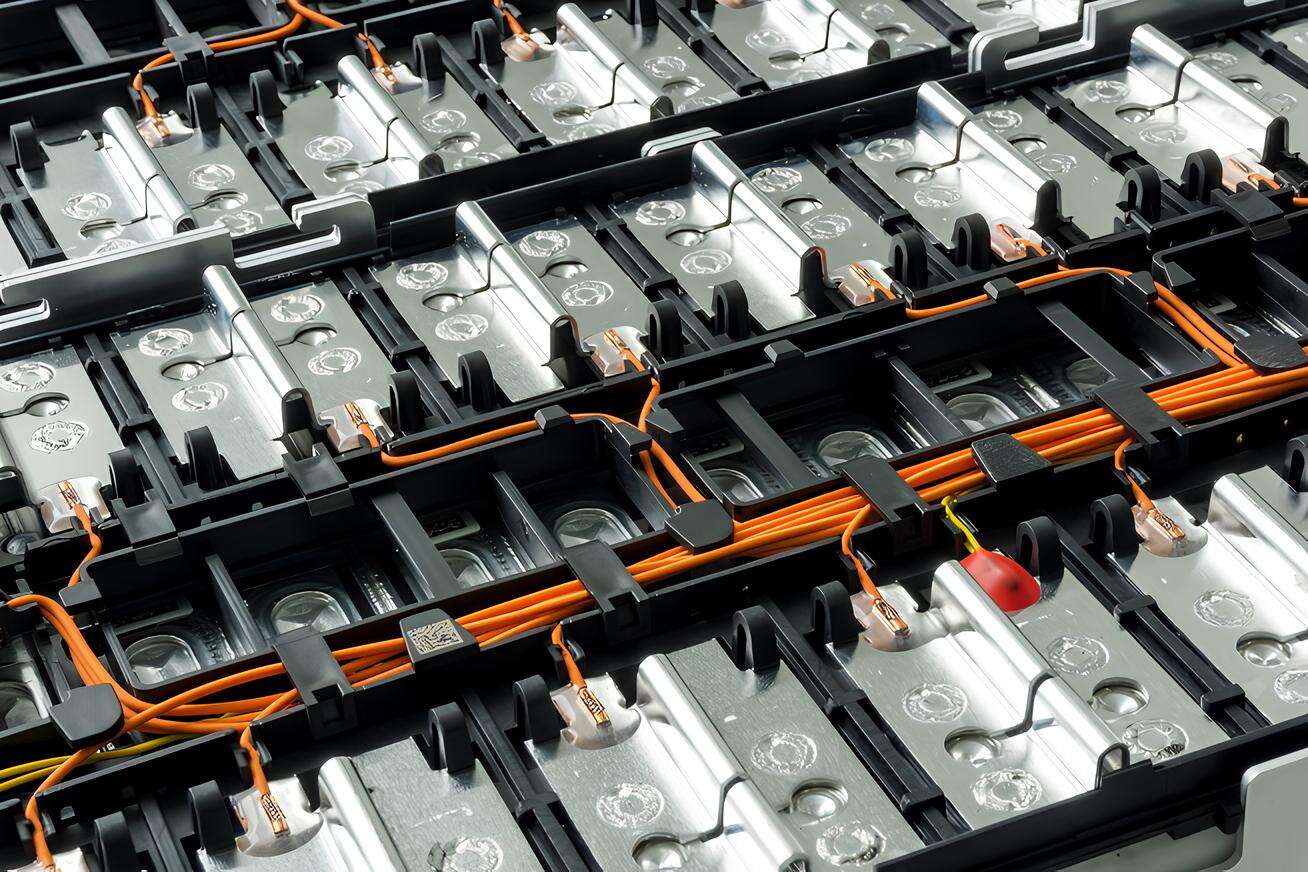

Choosing the right automated welding machine for battery manufacturing is not about chasing the latest technology blindly—it’s more like finding the perfect piece in a complex puzzle, precisely aligning with your production needs, budget ...

As the core component of most electric vehicles, prismatic battery packs must withstand thousands of charge-discharge cycles, extreme temperatures, and continuous vibrations. Their thin aluminum and copper tabs are highly vulnerable to damage, but mo...