In the field of rail transit operation and maintenance, metro wheelsets, as critical components, must have their epoxy resin coating (approximately 150-250 μm thick) completely removed before magnetic particle testing. Traditional chemical paint removal methods suffer from environmental pollution, health hazards to personnel, and low efficiency. To address this problem, DMK has innovatively launched an automated paint removal system based on composite lasers, providing a complete solution for green, efficient, and intelligent wheelset maintenance.

Contact Us

I. Innovative System Design: Through-Type Automated Operating Platform

The core of the technology designed by DMK is a highly integrated automated system. It adopts a through-type design, perfectly matching the rhythm of assembly line operations. The system mainly consists of a gantry frame, a composite laser cleaning system, a three-axis automated motion platform, and a wheelset conveying and rotating system. During operation, the wheelset is transported to the workstation by the conveying system and rotates at a constant speed. The composite laser cleaning head, mounted on the end of the three-axis platform, moves precisely along a predetermined trajectory, achieving full coverage cleaning of the paint layer on the wheelset surface. The entire process takes place in a closed environment, and the generated fumes and dust are handled by a purification system, reflecting DMK's strong commitment to environmental protection and safety.

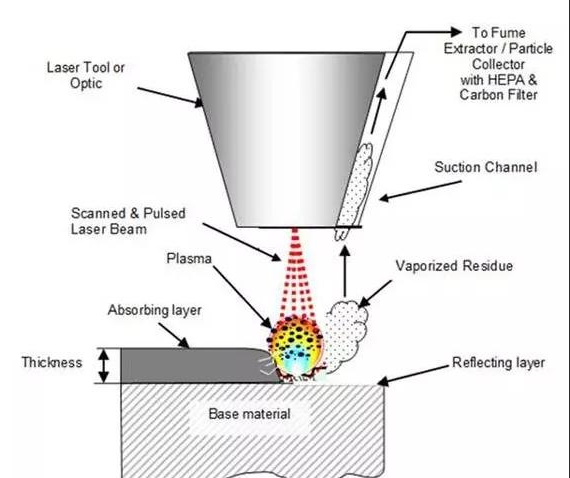

II. Core Technological Breakthrough: Composite Effect of Pulsed and Semiconductor Lasers

The excellent performance of this solution is due to the composite technology of pulsed lasers and semiconductor lasers adopted by DMK. The pulsed laser (high peak power) generates shock waves, causing the paint layer to fragment locally; while the continuous semiconductor laser (uniform energy distribution) provides stable heat input, weakening the bonding force between the paint layer and the substrate. The two work together through DMK's specially designed composite cleaning head, achieving a "1+1>2" cleaning effect. According to DMK's tests, the combination of a 300W pulsed laser and a 2000W semiconductor laser, while ensuring cleaning quality, also offers optimal economic efficiency, and its cleaning efficiency is significantly better than a single pulsed laser solution.

III. Precise Process Optimization: Coordinated Control of Trajectory and Parameters

To improve cleaning uniformity and avoid substrate damage, DMK's R&D team has deeply optimized the motion trajectory and laser parameters: First, they abandoned the traditional offset overlapping method and adopted an innovative double-helix cleaning trajectory. This trajectory effectively avoids repeated laser exposure in the overlapping area, preventing noticeable marks or substrate overheating, resulting in a more uniform surface quality. Secondly, through rigorous theoretical calculations and experimental verification, DMK determined the optimal combination of process parameters, including: pulse laser power at 100%, scanning speed at 8000 mm/s; semiconductor laser power at 90%, scanning speed at 7000 mm/s; wheelset rotation linear velocity at 21 mm/s, and laser head axial movement speed at 1.95 mm/s. Under these precise parameters, the cleaning overlap is accurately controlled, ensuring process consistency and high reliability.

IV. Effect Verification and Conclusion

The above technology and parameters provided by DMK were applied to on-site cleaning verification of subway wheelsets. The results showed that the system performed efficiently and thoroughly, completing the paint removal of a single wheelset in just 28 minutes, fully meeting the demanding production cycle requirements, and leaving no paint residue on the surface after cleaning. More importantly, rigorous third-party metal performance tests confirmed that the metallographic structure of the wheelset substrate remained unchanged before and after cleaning, and the surface morphology was intact, ensuring the mechanical performance and reliability of flaw detection, thus achieving non-destructive cleaning.

Summary

DMK has successfully applied composite laser automated cleaning technology to the paint removal of subway wheelsets. This technology, through the combined action of pulse and semiconductor lasers, a through-feed automated platform, and optimized spiral cleaning trajectories and process parameters, achieves efficient, environmentally friendly, and non-destructive high-quality cleaning. This not only provides a new technical standard for rail transit wheelset maintenance but also fully demonstrates DMK's profound technical strength and innovative capabilities in the field of high-end equipment intelligent maintenance, establishing its leading position in the broader industrial cleaning market.