I. Core Background and Technological Advantages Industry Pain Points: Traditional laser marking relies on tooling fixtures for positioning, resulting in high manual intervention, low efficiency, and high requirements for skilled...

Contact Us

I. Core Background and Technological Advantages

Industry Pain Points: Traditional laser marking relies on tooling fixtures for positioning, resulting in high manual intervention, low efficiency, and high requirements for skilled workers. It is also difficult to adapt to the marking needs of small products and irregularly shaped products.

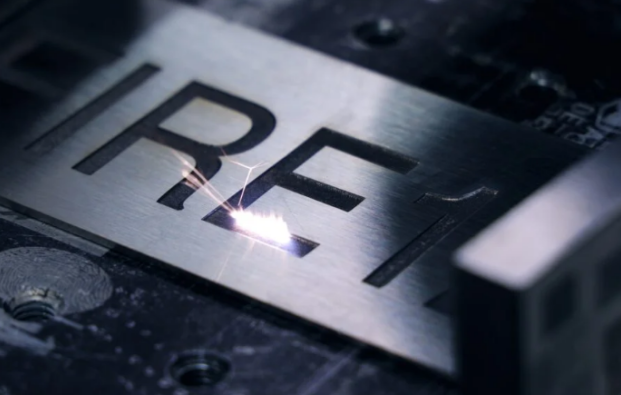

Technological Breakthrough: Visual positioning laser marking technology integrates electromechanical CNC, optoelectronics, and computer technology. Marking is assisted by a vision system, eliminating the need for fixtures and allowing products to be placed arbitrarily, achieving integrated detection, positioning, and marking.

Core Value: Improves marking accuracy and processing efficiency, reduces labor costs and equipment investment, and adapts to the automation needs of various industry production scenarios.

II. Device Design and Key Technologies

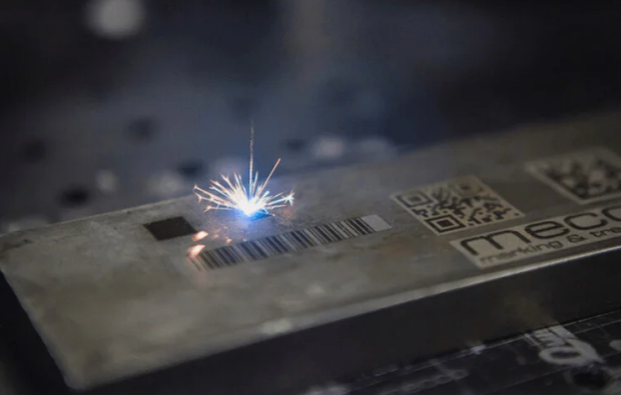

Overall Structure: Composed of a laser marking machine (fiber laser, galvanometer, reflector, etc.) and a vision positioning system (industrial camera, lens, LED light source, etc.), it has a small footprint and a compact structure.

Optical Path and Vision Coordination: Utilizing a 45° reflector design, the laser beam is reflected and applied to the workpiece. The industrial camera captures and positions the laser in real time, achieving precise marking through coordinate transformation and reducing human error.

Hardware Selection: Fiber lasers (high electro-optical conversion efficiency), Hikvision industrial cameras (3072×2048 resolution), and Golden Orange marking cards are selected to ensure equipment stability and marking effect.

Software Functions: Includes four main modules: image acquisition, recognition and positioning, coordinate transformation, and laser marking. It supports algorithms such as template matching and contour extraction, and is easy to operate.

III. Testing, Verification, and Application Results

Accuracy Performance: Through marking tests on ceramic products, the minimum marking error at the center of the field of view is only 0.027mm. The overall error is controlled within the allowable range, and the accuracy is superior to traditional mechanical positioning marking machines.

Application Advantages: Adaptable to round, square, and irregularly shaped products; eliminates the need for positioning trays and fixtures, shortening the processing cycle; especially suitable for efficient marking of miniature products.

DMK, deeply rooted in the laser equipment field, has integrated its core vision positioning technology into its laser marking product line. Its vision positioning laser marking equipment perfectly aligns with the design philosophy of "high precision, automation, and high adaptability," and features industry-specific upgrades in hardware selection and optical path optimization, meeting the marking needs of various fields such as manufacturing, electronic components, and precision parts.

If you are facing challenges such as low efficiency, insufficient precision, and high labor costs associated with traditional marking methods, please contact DMK for a free consultation and obtain a customized vision positioning laser marking solution to unlock a new experience in automated production!