Choosing the right automated

welding machine for battery manufacturing is not about chasing the latest technology blindly—it’s more like finding the perfect piece in a complex puzzle, precisely aligning with your production needs, budget plans, and long-term goals. The chemical composition, production scale, and application scenarios of different batteries determine the core direction of the welding solution. This article breaks down the key factors for selection, compares the pros and cons of mainstream welding technologies, helps you avoid common pitfalls, and boosts both production line efficiency and quality.

I. Clarify Core Requirements: Lock Welding Specifications Based on Battery Characteristics

The first step in selection is to accurately position your needs, screening suitable

welding machine specifications around core dimensions such as battery type, performance indicators, and speed requirements:

1. Determine Performance Parameters by Battery Type

Batteries for different purposes have significantly varying welding performance requirements:

- Tensile strength: Tab welding for small cylindrical batteries requires a tensile strength of 30–50 Newtons; structural busbar welding for electric vehicles increases to 80–100+ Newtons. Always verify with tensile tests after selection.

- Resistance control: Each welding joint in high-current battery packs must have a resistance below 100μΩ. Excessive resistance generates additional heat, directly shortening battery lifespan.

- Sealing precision: The sealing pin must withstand pressure exceeding 1.1 MPa, while the safety pressure relief valve needs to burst within the range of 0.4–0.7 MPa. This narrow window can only be met by high-precision welding methods.

2. Match Speed Requirements to Production Scale

Welding speed directly determines production efficiency and should be flexibly selected based on target output:

- For prismatic battery welding, the mainstream speed of modern production lines is 200 mm/s; equipment slower than 70 mm/s is only suitable for R&D scenarios.

- In module welding, professional production lines can reach 15 cells/second, while standard lines operate at approximately 4 cells/second. You can reverse-calculate the required equipment speed based on your capacity goals.

- Most battery welding involves 8 mm circular welds. Focus on equipment stability during continuous operation at this specification to avoid failures due to overload.

3. Material Combinations Determine Welding Process Direction

Battery cathodes are mostly aluminum, anodes are copper, and tabs can be nickel, nickel-plated steel, copper, aluminum, or nickel-plated copper. Different material combinations directly limit welding process choices:

- Internal electrode foils: Thin and heat-sensitive, ultrasonic welding is the only option to avoid thermal damage.

- Copper-aluminum dissimilar metal connections: Laser welding is strictly prohibited, as it forms brittle compounds prone to cracking under vibration. Use ultrasonic welding or resistance welding—requirements explicitly specified in most automotive industry standards.

- Same-metal pairs (e.g., Cu-Cu, Al-Al): Offer greater flexibility. Fiber laser welding is the fastest; micro-TIG welding is suitable for thick copper blocks; resistance welding meets the reliability needs of basic tab connections.

- Multi-layer stacked structures: Laser welding excels here, easily penetrating 1.0 mm+ multi-layer materials. Resistance welding requires complex custom force curves, making operation challenging.

4. Tab Thickness Influences Process Selection

Welding processes need adjustment based on tab thickness:

- Nickel sheets ≤ 0.18 mm: Resistance spot welding is sufficient without special settings.

- Nickel sheets 0.18–1.0 mm: Require edge thinning, slotting, or preforming to control current flow and weld nugget formation.

- Materials > 1.0 mm: Laser welding is preferred, handling multi-layer materials in a single pass—ideal for connecting tab stacks to busbars.

- Thick copper welding: Micro-TIG welding is suitable if a single solid weld nugget is required.

II. Comparison of Four Core Welding Technologies: Select the Optimal Solution on Demand

Modern battery production lines primarily use resistance spot welding, ultrasonic welding, laser welding, and other technologies. Each has unique strengths in specific applications, requiring comparison based on individual needs:

1. Resistance Spot Welding: The Workhorse for Basic Tab and Terminal Connections

Resistance spot welding compresses metal components with high pressure and passes high current to form welds in milliseconds. It is cost-effective, easy to operate, and widely used for battery tab and terminal connections. Modern systems precisely control weld nugget size and monitor welding pressure in real time but suffer from electrode wear and potential bending deformation of thin materials. In EV battery packs, resistance spot welding is often combined with structural adhesives to balance long-term strength and moisture resistance.

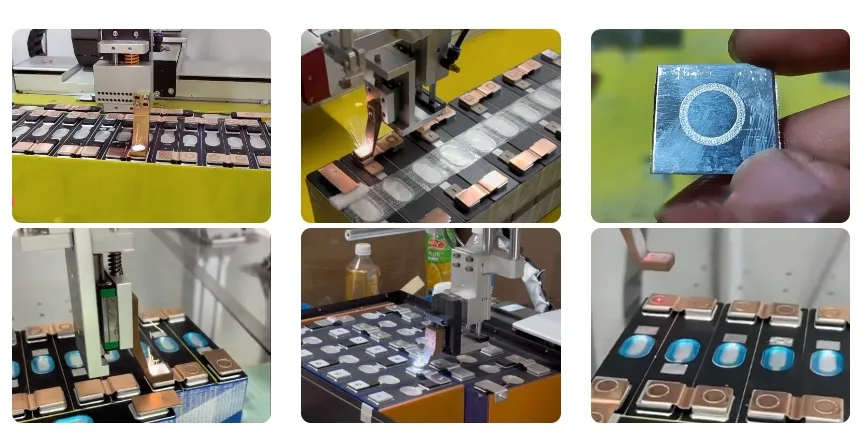

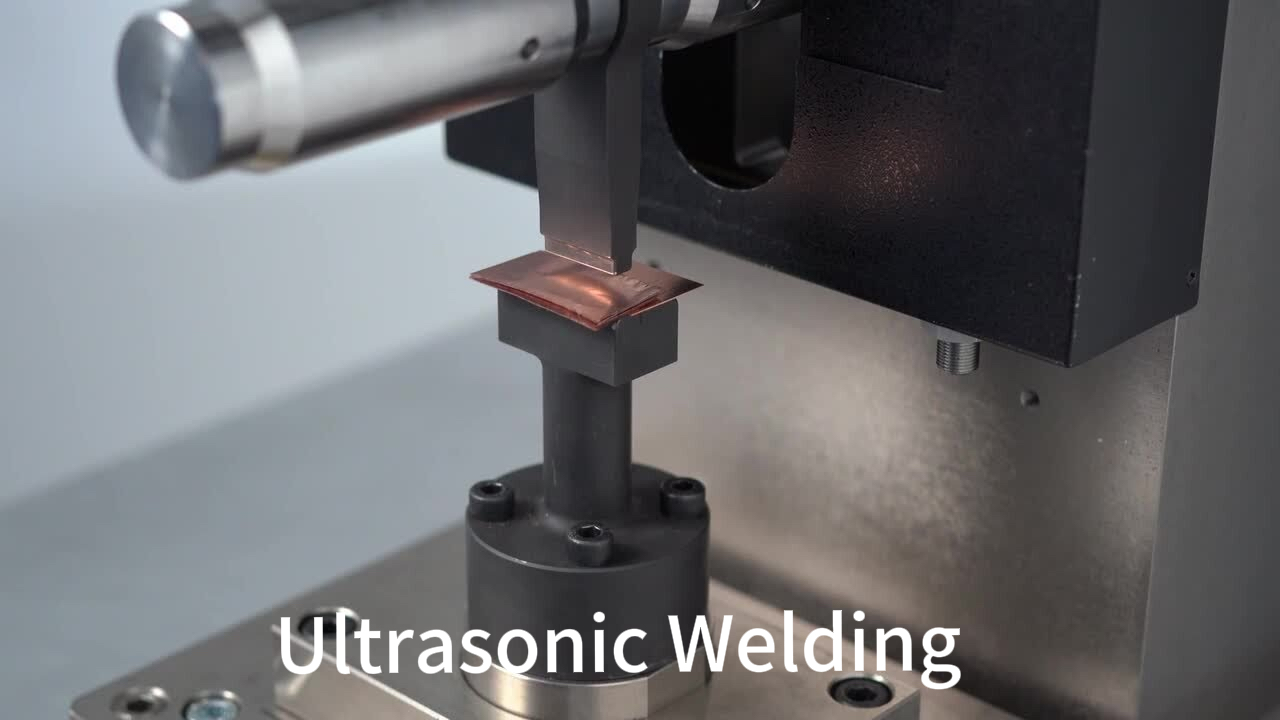

2. Ultrasonic Welding: The Only Choice for Thin Foil Welding

Ultrasonic welding bonds thin, heat-sensitive electrode foils through vibration without melting, offering fast, clean, and automatable advantages—it is the mandatory choice for pre-welding internal electrode foils. However, it has limitations with thick stacks and multi-material combinations. The mainstream solution is "hybrid welding": ultrasonic welding for pre-welding and laser welding for final connections, ensuring joint strength and design flexibility.

3. Laser Welding: The Leader in High-Speed, High-Precision Scenarios

Laser welding has become a rapidly adopted technology due to its non-contact, consumable-free, and low-maintenance benefits, with core advantages including:

- Speed: 5–10 times faster than traditional technologies, suitable for large-scale mass production.

- Compatibility: Fiber lasers efficiently process copper, aluminum, nickel, steel, etc.; blue/green lasers further improve absorption rates for copper/aluminum, optimizing welding quality.

- Flexibility: Pulsed lasers enable strict temperature control; continuous-wave lasers maximize throughput; brazing or wire-feed lasers connect dissimilar metals or manufacture thick busbars without brittle welds.

4. Quick Selection Table for Technology Matching

| Application Scenario |

Recommended Welding Technology |

Core Advantages |

Notes |

| Pre-welding of internal electrode foils |

Ultrasonic Welding |

No thermal damage, suitable for thin foils |

Not for thick stacks or dissimilar metals |

| Final welding of tabs for thick stacked batteries |

Laser Welding |

Strong penetration, reliable connections |

Exercise caution with copper-aluminum dissimilar connections |

| High-volume seam welding of prismatic batteries |

Fiber Laser/Blue Laser |

Fast speed, high stability |

Preferred for high-copper designs |

| Structural housing joint welding |

Resistance Spot Welding |

Fast speed, long-term durability |

Combine with adhesives for moisture resistance |

III. Key Auxiliary Factors: Details Determine Selection Success

Beyond core requirements, equipment control functions, energy consumption, and automation compatibility significantly impact long-term usability:

1. Control Functions Distinguish Equipment Grades

Advanced control functions are critical for ensuring welding quality:

- DC inverter resistance welders: Require fast, controllable pulses, real-time monitoring, and polarity switching. Advanced systems track electrode force and displacement; high-end scenarios (e.g., aerospace standards) demand support for formal Welding Procedure Specifications (WPS).

- Laser welders: Offer significant speed advantages for thin-layer battery welding with non-contact, consumable-free features. Verify temperature control precision and process monitoring capabilities during selection.

2. Comprehensive Cost Considerations

Cost structures vary across welding technologies:

- Laser welders: Higher upfront investment but no subsequent consumable costs; faster welding speeds reduce long-term unit product welding costs.

- Resistance welders: Lower initial investment but ongoing electrode replacement costs.

- Ultrasonic welders: Medium upfront and maintenance costs, only necessary for specific material characteristics.

Conclusion

Selecting an automated welding machine for battery manufacturing hinges on "adaptation" rather than "novelty." First, clarify your battery type, material combinations, production speed, and quality requirements. Then compare mainstream welding technologies based on application scenarios, considering costs and long-term usability. We recommend requesting equipment demonstrations to simulate real production bottlenecks and consulting experts familiar with your battery type. Only a welding machine precisely matched to your needs can truly boost production efficiency. For further refined selection plans, contact professional teams for customized advice.