The safety of laser technology in glass marking is a core concern for users. The answer is clear: laser marking on glass is completely safe when using professional equipment and strictly following operational procedures. For professional manufacturers, safety is not an additional feature but the core logic of laser equipment design. Through the R&D of modern, professional equipment, risks are reduced at the source, enabling a safe, clean, and reliable processing workflow. This article breaks down the safety principles of glass laser marking, analyzes potential risks and equipment protection designs, and provides practical safety specifications to help you fully grasp the key safety points of glass marking.

I. Safety Basics: Understanding Laser Marking Principles and Glass Characteristics

The safety of glass laser marking is built on a deep understanding of technical principles and material properties. Only by clarifying the interaction mechanism between lasers and glass can we understand the necessity of safety measures and how equipment design addresses inherent challenges.

1. Laser Marking Principles: Two Core Processing Methods

Laser marking is like using a high-precision "light pen" to focus high energy on tiny areas of the glass surface. The marking effect (frosted, engraved lines, internal images) depends on the energy application method, mainly divided into two categories:

- Thermal processing (CO₂ laser): The heat from CO₂ lasers is easily absorbed by glass. Concentrated thermal energy rapidly melts or vaporizes trace amounts of material on the glass surface, and may even generate controlled fine cracks, ultimately forming clear and durable marks;

- Photochemical processing (UV laser): UV lasers have higher photon energy, and their core principle is to break chemical bonds inside the glass, locally changing the material structure. Due to minimal heat generation, it is called "cold processing," making it particularly suitable for fine marking scenarios.

The core of safe operation is to accurately limit these high-energy reactions to the preset marking area, preventing energy diffusion or deviation from causing risks.

2. Glass Characteristics: Why Special Safety Protection is Needed?

The inherent properties of glass determine that its marking process requires extra caution, with core challenges focusing on two points:

- Risk of thermal stress cracking: Glass has poor thermal conductivity. Rapid heating by the laser causes surface expansion, while the interior remains low-temperature and rigid, forming strong internal stress. If the stress exceeds the material's bearing limit, it will trigger cracks or even fractures;

- Protection of surface integrity: The goal of safe marking is to achieve the desired visual effect (frosted, deep engraving, etc.) while maintaining the overall structural integrity of the glass. This is especially crucial for special products such as thin-walled containers and tempered glass.

This is why laser equipment needs to precisely optimize parameters such as power, speed, and pulse duration. The software preset function of professional equipment has simplified the parameter debugging process for users.

II. Potential Risks and Equipment Safety Protection Design

Glass laser marking involves three core potential risks, but modern professional equipment has minimized these risks through engineering design. Understanding risk categories and protection mechanisms helps clearly judge equipment safety.

1. Three Core Potential Risks

- Radiation hazards: This is the most direct and significant risk. Invisible laser beams and their specular reflections on smooth glass surfaces can transfer high energy to eye tissue or skin in milliseconds, causing permanent damage. The hazard level varies with laser wavelength, so targeted protection is essential;

- Process byproduct hazards: The marking process generates trace airborne substances. In deep engraving mode, micro-fragment ejection or molten material spatter may occur; some processes produce fine fumes containing vapors and condensates. Although this can be reduced by optimizing parameters, targeted treatment is still required;

- General operational risks: Including common risks of industrial equipment, such as electrical hazards from high-voltage power supplies and capacitors in laser sources, mechanical pinch hazards from moving parts like gantries and galvanometer scanners, and fire hazards where nearby flammable materials (packaging, paper, dust) may be ignited by unfocused or deviated beams.

2. Multi-Layer Safety Protection Design of Professional Equipment

The safety protection of modern laser equipment is "built-in rather than added," eliminating risks from the source through a multi-layer protection architecture, mainly including three core designs:

- Isolation and interlock protection (first line of defense): The laser beam is completely enclosed inside the system to prevent accidental leakage; access doors are equipped with hardware interlock devices that immediately cut off the laser power when opened; dedicated observation windows can block specific laser wavelengths while allowing operators to safely monitor the processing process;

- Clean operation optimization: Through excellent beam quality and optimized mechanical structure, ensure maximum energy acts on the target area, reducing excess heat, smoke, and debris generation; the software has built-in material-specific parameter presets to help users achieve ideal effects within safe power ranges, avoiding risks caused by improper parameters;

- Compliance and reliability guarantee: All equipment designs meet or exceed strict international safety standards, verified through independent certifications, ensuring operator safety is prioritized in every engineering link.

III. Practical Safety Specifications: From Personal Protection to Environmental Management

Professional equipment is the foundation of safety, but strict operational procedures are an indispensable "safety moat." Every detail from personal protection, operating processes to environmental management directly affects marking safety.

1. Personal Protective Equipment (PPE): Essential First Line of Defense

Personal protective equipment is the direct safety guarantee for operators and must be strictly equipped:

- Core protection: Laser safety goggles are crucial. They must be selected according to the laser wavelength of the equipment to effectively block specific light (ordinary glasses provide little to no protection and may even increase risks);

- Auxiliary protection: Depending on the operation scenario, protective gloves and other clothing may be needed to avoid accidental contact with high-temperature areas or debris.

2. Standard Operating Procedures (SOP): Eliminating Operational Risks

Standardized operating processes can avoid human errors, with core steps as follows:

- Pre-start inspection: Verify that all safety interlocks are functional; clean the work area to remove reflective materials, debris, and flammables; confirm that the exhaust or ventilation system is operating (if applicable); check the cleanliness of the laser focusing lens to ensure optimal and safe beam quality;

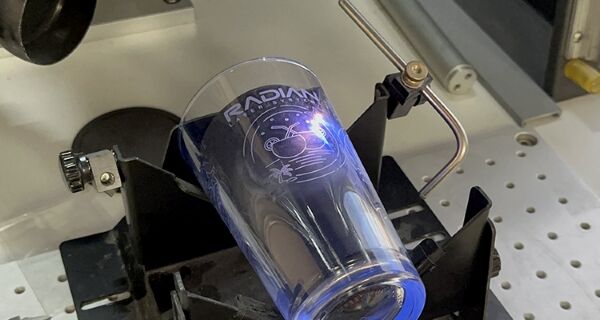

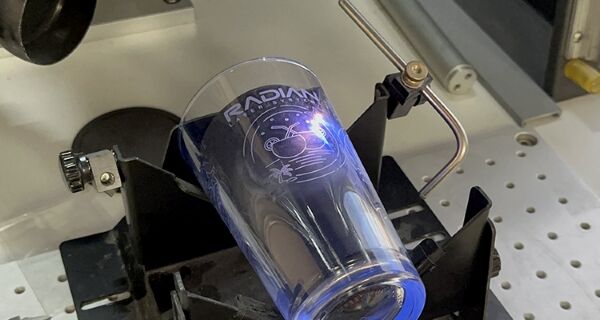

- Workpiece fixation: Glass workpieces must be firmly clamped in place. Unfixed glass may move during marking, leading to unpredictable beam reflections or marking errors;

- In-operation monitoring: Never leave the machine unattended while it is running; continuous monitoring is crucial for timely intervention. Similarly, be familiar with the location and function of the Emergency Stop (E-Stop) button to respond immediately to any unexpected situations.

3. Work Environment Management: Creating a Safe Operation Space

Reasonable organization of the physical workspace can further reduce risks and strengthen safe behaviors:

- Area demarcation: Clearly mark the laser work area with floor markings or barriers. Restrict access to authorized personnel only;

- Safety signage: Post prominent warning signs at all entrances to the area, indicating "Laser in Use," "Danger - Invisible Laser Radiation," and the specific laser wavelength/class;

- Adequate ventilation: Even for low-smoke processes, ensure good overall ventilation in the room. For enclosed machines, use any integrated or recommended smoke extraction system to maintain air quality.

4. Human Factors: Training and Authorization

No matter how safely designed laser marking machines are, safe operation relies on qualified personnel. Effective training and strict authorization are crucial. All operators must complete formal training and refer to the operation manual. Only trained and certified personnel are allowed to operate the equipment, ensuring accountability and a strong safety culture. These measures together form a comprehensive "safety moat" to protect workplace safety.

Conclusion

The high safety of glass laser marking stems from inherently safe professional equipment, comprehensive risk awareness, and consistent safe operating standards. Choosing a laser marking machine that meets safety standards is the core prerequisite for ensuring safety. Whether it is a UV laser, CO₂ laser, fiber laser, or hybrid laser system, professional equipment can meet precise marking needs while fully protecting the safety of operators and workflows. If you need further information on equipment selection or safe operation details, feel free to consult a professional team for customized advice.