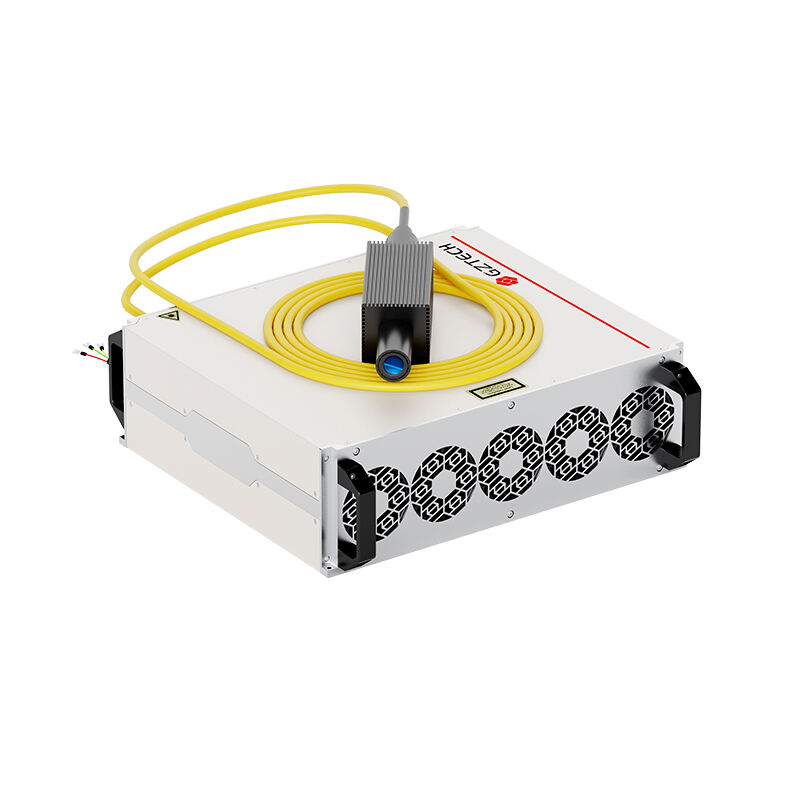

YFPN-200-GLE Q-Switched Pulsed Fiber Laser Source

Product Description

The YFPN-200-GLE is a high-performance Q-switched pulsed fiber laser designed for precision industrial applications such as marking, engraving, cutting, drilling, and surface treatment. Featuring an average output power of 200W, a single-pulse energy of 1.5mJ, and electro-optical conversion efficiency over 20%, this laser delivers stable, high-energy output with exceptional reliability.

Its built-in red-light pointer simplifies alignment and positioning, while its maintenance-free design ensures long-term operation with minimal downtime. Ideal for production environments that demand high throughput, consistent quality, and durable marking across a variety of metal and non-metal materials.

Key Features

🔦 Q-Switched Pulsed Output for high peak power and precision

⚡ 200W Average Power with 1.5mJ Single Pulse Energy

🎯 Electro-Optical Conversion Efficiency > 20% for reduced power consumption

🔴 Red Laser Pointer for quick and easy visual alignment

🛠️ Maintenance-Free Design ensures long-term, reliable operation

🔄 Stable Output for consistent marking, engraving, or drilling quality

Specifications

| Parameter | Specification |

|---|---|

| Model | YFPN-200-GLE |

| Laser Type | Q-switched pulsed fiber laser |

| Average Output Power | 200W |

| Single Pulse Energy | 1.5 mJ |

| Electro-Optical Efficiency | > 20% |

| Red Light Pointer | Integrated for visual alignment |

| Operation Mode | Pulsed (Q-switched) |

| Cooling Method | Typically air-cooled or as specified |

| Maintenance | Maintenance-free design |

| Wavelength | Typically around 1064 nm (TBD) |

| Output Stability | High |

Applications

Laser Marking – High-speed marking on metals, plastics, and ceramics

Laser Deep Engraving – Precision engraving of logos, codes, and designs

Laser Cutting – Suitable for thin metals and non-metal substrates

Laser Drilling – Micro-drilling in electronics and automotive parts

Surface Treatment – Texturing, cleaning, or coating removal for industrial surfaces

EN

EN

AR

AR CS

CS NL

NL FR

FR DE

DE IT

IT JA

JA KO

KO PL

PL PT

PT RU

RU ES

ES UK

UK TH

TH TR

TR