DMK Jewelry Spot Welding Machine - 150W High Power + 45J Pulse Energy + Microscope + CCD Camera Positioning - Special for Metal Jewelry Welding/Repair

Product Description

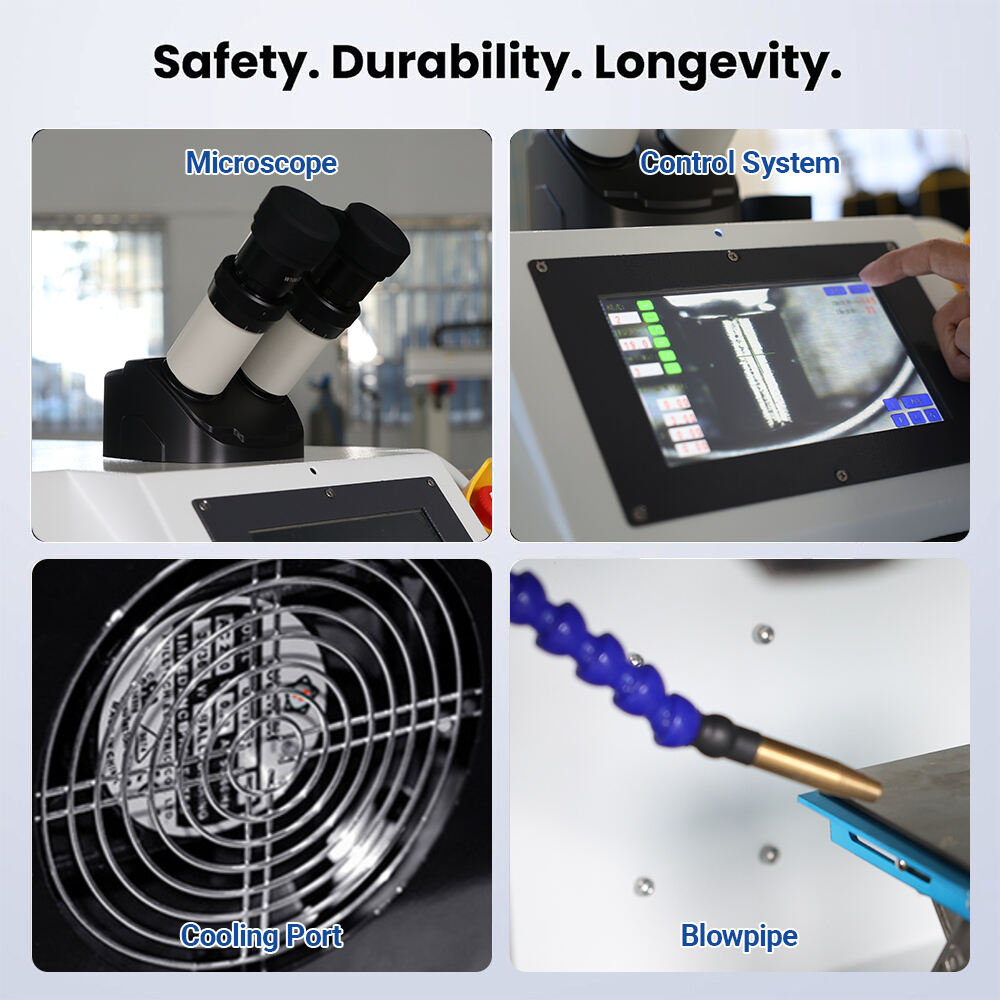

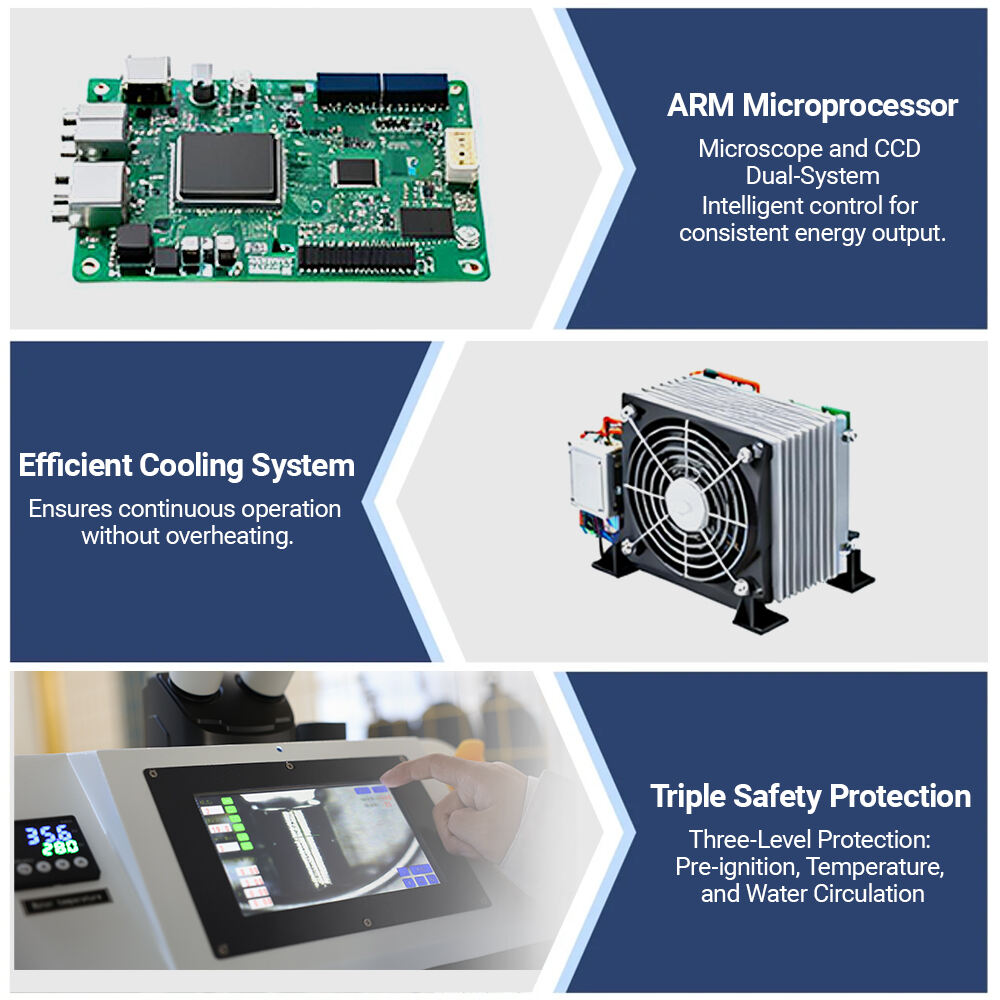

DMK Jewelry Spot Welding Machine is a high-precision laser welding equipment specially designed for metal jewelry welding and repair. It adopts a pulse laser power control system, combined with L-C resonant charging and capacitor-inductor energy storage network, with an ARM microprocessor as the core control unit. It can accurately adjust the output energy and repetition frequency, ensuring stable overall performance and precise welding effect.

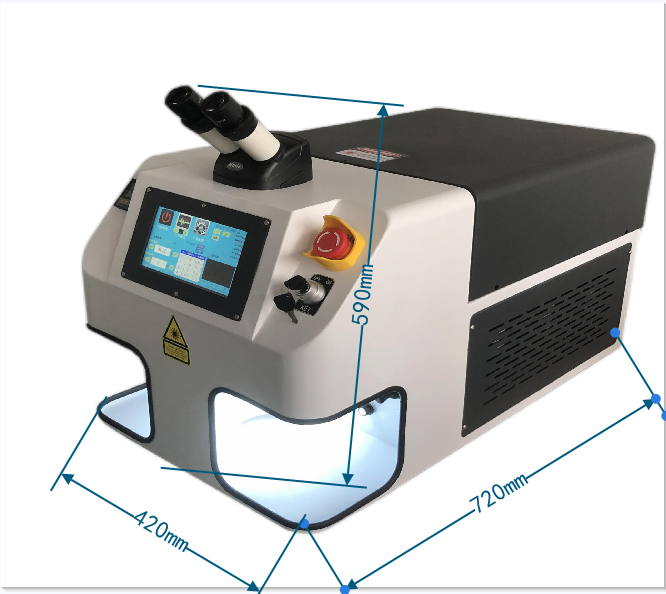

Equipped with a 1064nm wavelength laser, the equipment has a maximum laser power of 150W and a maximum pulse energy of 45J. The pulse width and frequency can be adjusted in stages to meet the spot welding needs of various metal jewelry. It is equipped with a dual positioning system of microscope + CCD camera, which can clearly observe the welding position and achieve precise alignment. Adopting water circulation air cooling mode, it ensures long-term stable operation of the equipment. Multiple protection mechanisms (pre-ignition protection, temperature protection, cooling water circulation interlock protection) guarantee operational safety.

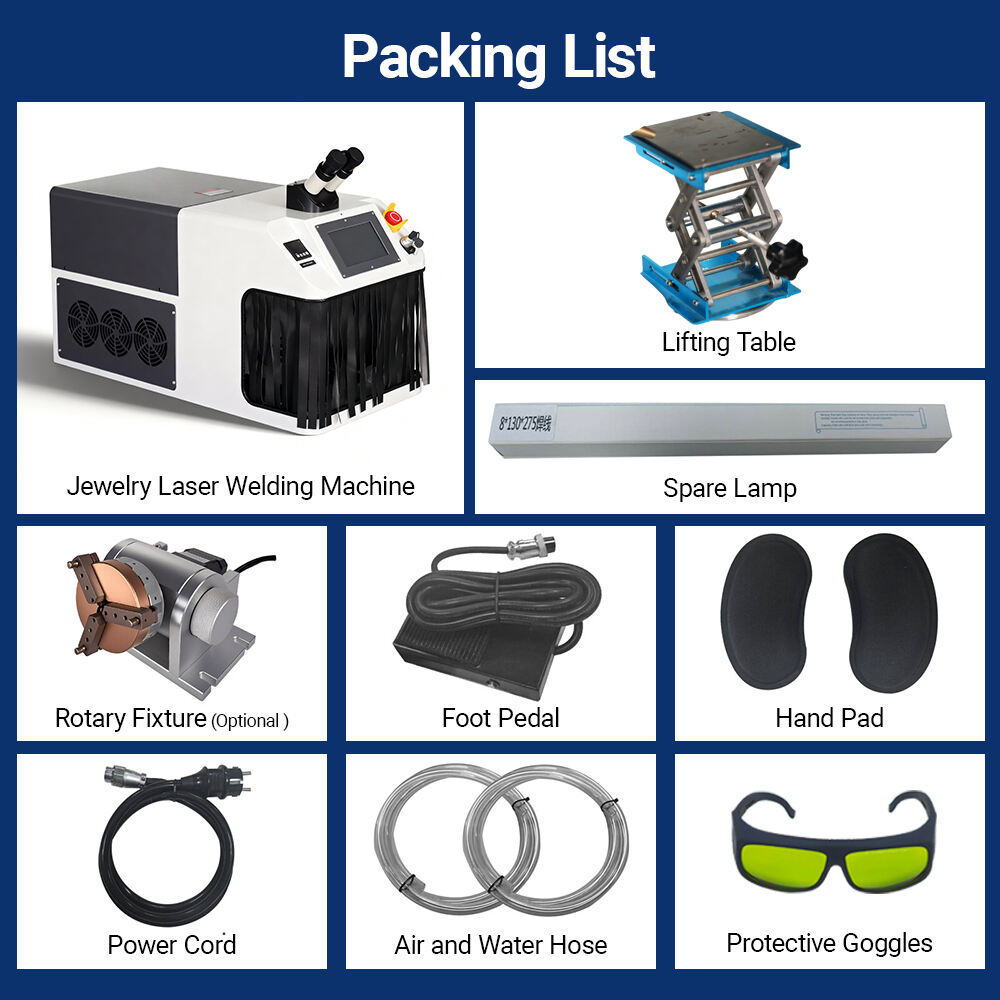

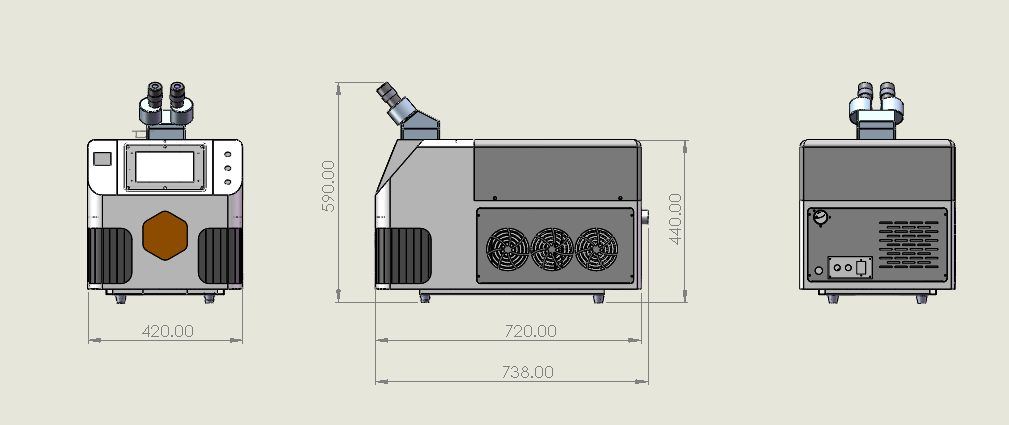

With a compact body (720×420×590mm) and a net weight of only 50kg, the equipment is easy to move. The operation interface is simple and easy to understand, supporting the storage and recall of 30 sets of welding programs, which can quickly adapt to different jewelry welding processes. It is widely used in welding and repair scenarios of various metal jewelry, and is an efficient and precise welding solution for the jewelry processing industry.

Product Parameters

| Parameter Category | Specific Parameters |

|---|---|

| Core Laser Parameters | - Laser Wavelength: 1064nm - Maximum Laser Power: 150W - Maximum Laser Pulse Energy: 45J - Pulse Width: 0.1-15.0ms - Pulse Frequency: 1.0-15.0Hz (Adjustable in Stages) |

| Positioning and Welding Parameters | - Aiming and Positioning: Microscope + CCD Camera System - Applicable Scenarios: Welding and Repair of Various Metal Jewelry - Program Storage: Supports 30 Sets of Welding Programs |

| Power Supply and Energy Consumption Parameters | - Host Power Consumption: ≤2.8KW - Power Requirement: AC220V±5%, 50HZ |

| Cooling and Protection Parameters | - Cooling Mode: Water Circulation Air Cooling - Protection Mechanisms: Pre-ignition Protection, Temperature Protection, Cooling Water Circulation Interlock Protection |

| Shape and Weight Parameters | - Host Dimensions (Length×Width×Height): 720×420×590mm - Overall Net Weight: 50kg - Weight After Packaging: 80kg |

| Operating Environment Parameters | - Ambient Temperature: ≤30℃ |

Other Details

1、Equipment Composition and Operation

- Core Components: Host (built-in laser power supply, energy storage circuit, control circuit, etc.), Microscope, CCD Camera System, Foot Switch, Water Circulation Cooling System.

- Operation Process: Connect the power supply (ensure good grounding) → Install the foot switch and microscope → Turn on the emergency stop switch and key switch → Fill the water tank → Start the equipment → Select/set the welding program → Position the welding location → Step on the foot switch to start welding.

- Key Operations: Welding parameters can be adjusted according to jewelry material and process requirements, supporting precise adjustment of pulse width, frequency, power, etc.; the CCD cross cursor can be calibrated through screen operation to ensure accurate alignment of the welding spot.

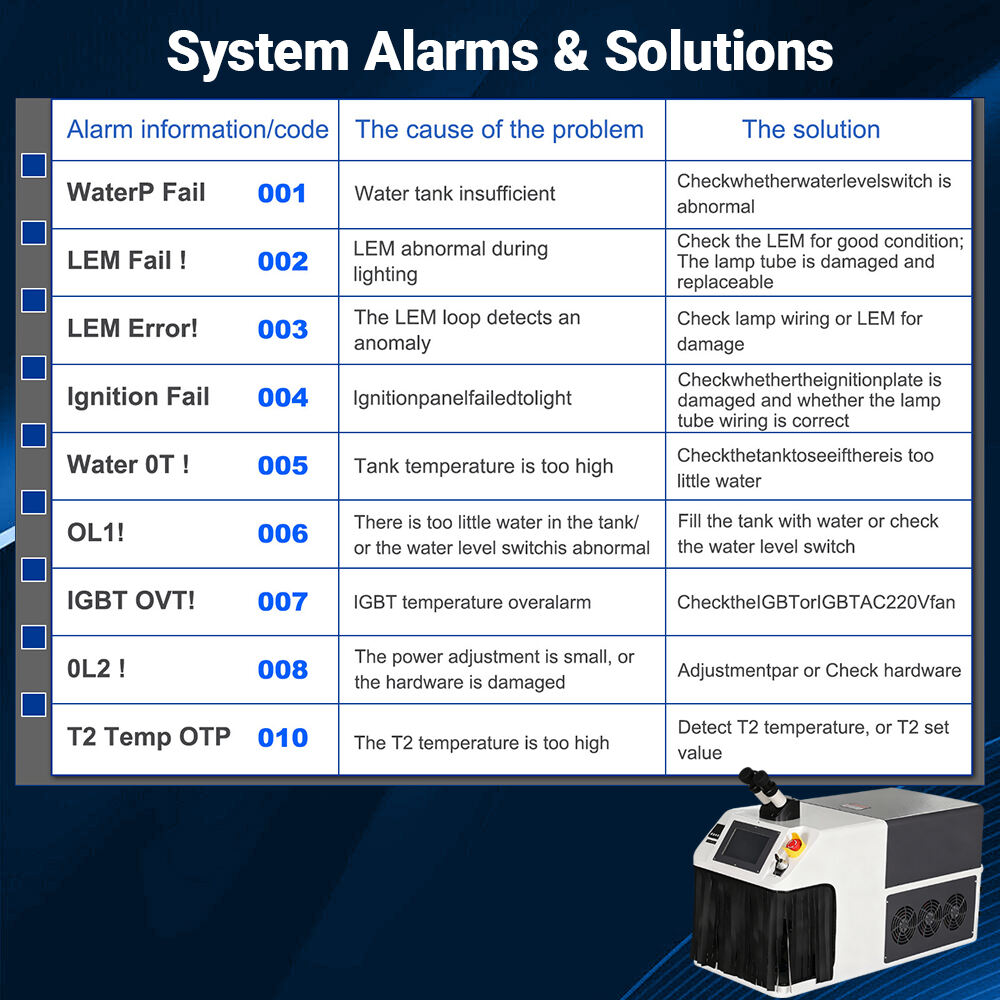

2、Maintenance and Troubleshooting

| Daily Maintenance | Common Troubleshooting |

|---|---|

| - Cooling System: Fill with distilled water or deionized water, replace the internal circulating water every 2 months; drain the water tank when not in use for a long time, and store indoors after power-off and draining in environments below 0℃. - Optical Components: Regularly wipe the laser objective protective lens and microscope eyepiece with lens paper dipped in anhydrous ethanol to avoid dust affecting observation and welding effects. - Equipment Storage: Avoid strong mechanical vibration to prevent optical path structure deviation. | - No Display on Screen: Check if the power switch is closed, the plug is in good contact, and confirm that the emergency stop switch and key switch are turned on. - Unable to Ignite the Lamp: Check if the xenon lamp is blackened after power-off, and have professional personnel replace the xenon lamp. - Water Circulation Error: Check the water level of the water tank and troubleshoot the water pump fault. - Reduced Laser Output Power: Replace the aging crystal laser rod. |

3、Usage Precautions

- The equipment must be grounded in strict accordance with electrical standards to avoid electrostatic interference.

- The foot switch is a passive input; do not connect an external power supply to prevent equipment damage.

- Wear professional protective equipment during welding to avoid laser radiation damage.

- When the ambient temperature exceeds 30℃, take cooling measures to ensure stable operation of the equipment.

Sample Display

|

|

EN

EN

AR

AR CS

CS NL

NL FR

FR DE

DE IT

IT JA

JA KO

KO PL

PL PT

PT RU

RU ES

ES UK

UK TH

TH TR

TR