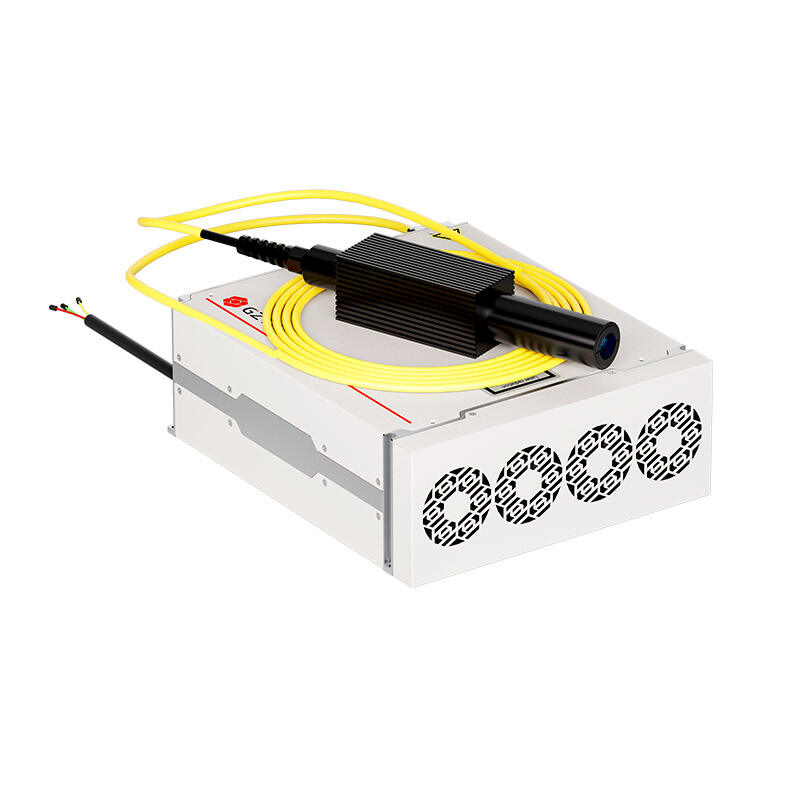

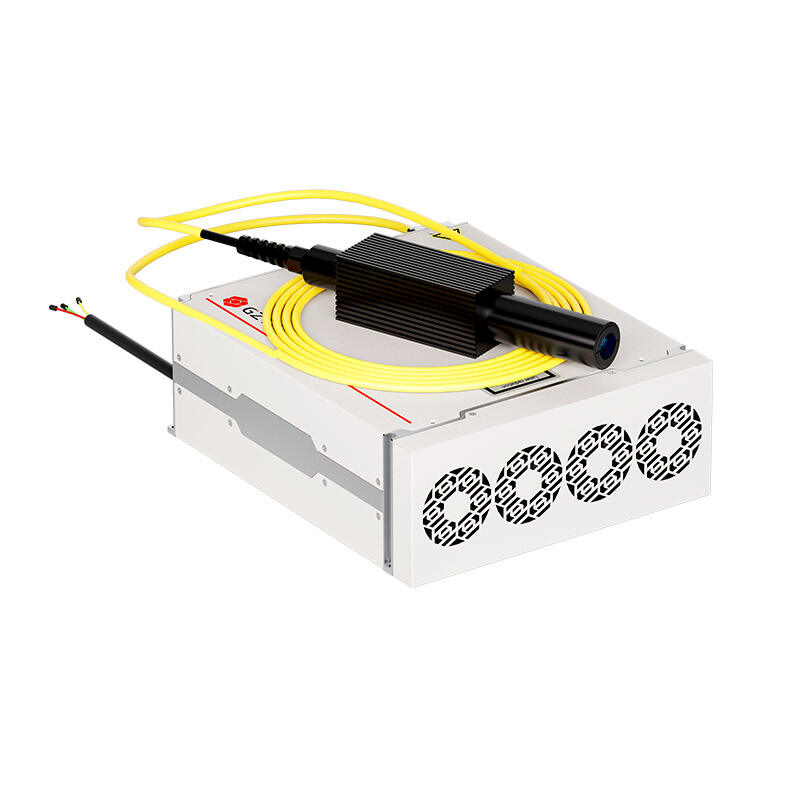

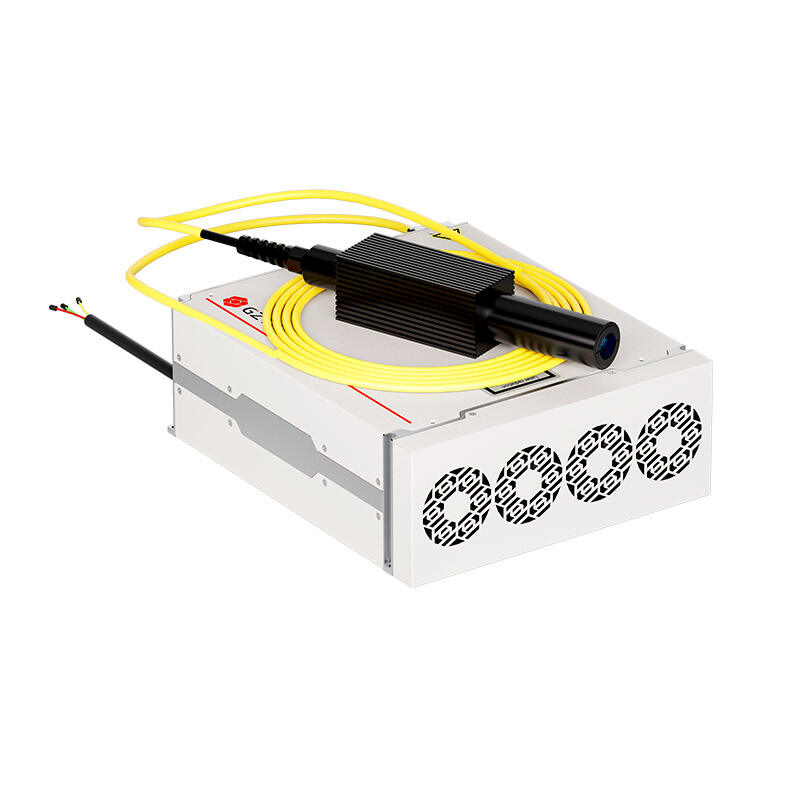

YFPN-100-GLE Q-Switched Pulsed Fiber Laser Generator

Product Overview

The YFPN-100-GLE is a high-power, Q-switched pulsed fiber laser designed for demanding industrial applications. With 100W average output power and single pulse energy of 1.25mJ, this model delivers excellent performance for high-speed, high-precision material processing. It offers a >20% electro-optical conversion efficiency, integrated red light positioning, and a maintenance-free design—ensuring stable, long-term operation in both OEM systems and automated production lines.

Key Features

⚡ 100W Average Power Output

Enables high-throughput processing with consistent energy delivery.💥 1.25mJ Single Pulse Energy

Ensures strong, stable pulses ideal for deep engraving and micromachining.🔄 Q-Switched Nanosecond Pulses

Perfect for high-precision tasks like fine marking and drilling with minimal thermal effects.🔋 >20% Conversion Efficiency

Reduces energy waste, simplifies cooling systems, and lowers operational costs.🎯 Integrated Red Laser Pointer

Simplifies focus alignment and enhances system usability.🔧 Maintenance-Free Operation

Long lifespan and high reliability for uninterrupted industrial use.

Technical Specifications

| Parameter | Specification |

|---|---|

| Model | YFPN-100-GLE |

| Laser Type | Q-switched Pulsed Fiber Laser |

| Average Output Power | 100W |

| Single Pulse Energy | 1.25mJ |

| Electro-Optical Efficiency | >20% |

| Center Wavelength | 1064nm |

| Pulse Duration | Nanosecond range |

| Cooling Method | Air Cooling |

| Red Light Pointer | Integrated |

| Operation Mode | Maintenance-Free |

| Typical Applications | Marking, Engraving, Cutting, Drilling, Surface Treatment |

Applications

Laser Marking

High-speed, high-contrast marking on metals, plastics, and composites.Deep Engraving

Ideal for molds, nameplates, and tools that require durability and depth.Precision Cutting

Clean, narrow kerfs on thin materials with excellent edge quality.Laser Drilling

Micron-scale holes in electronic components and precision hardware.Surface Treatment & Texturing

Modify texture, adhesion, reflectivity, or friction properties of surfaces.

EN

EN

AR

AR CS

CS NL

NL FR

FR DE

DE IT

IT JA

JA KO

KO PL

PL PT

PT RU

RU ES

ES UK

UK TH

TH TR

TR