UV Laser Marking Machine - 355nm Short Wavelength + 3W-30W Adjustable Power + Ultra-fine Marking + Water-cooled Constant Temperature - For Cosmetics/Medical/Electronic Components/Flexible PCB Marking

Product Description

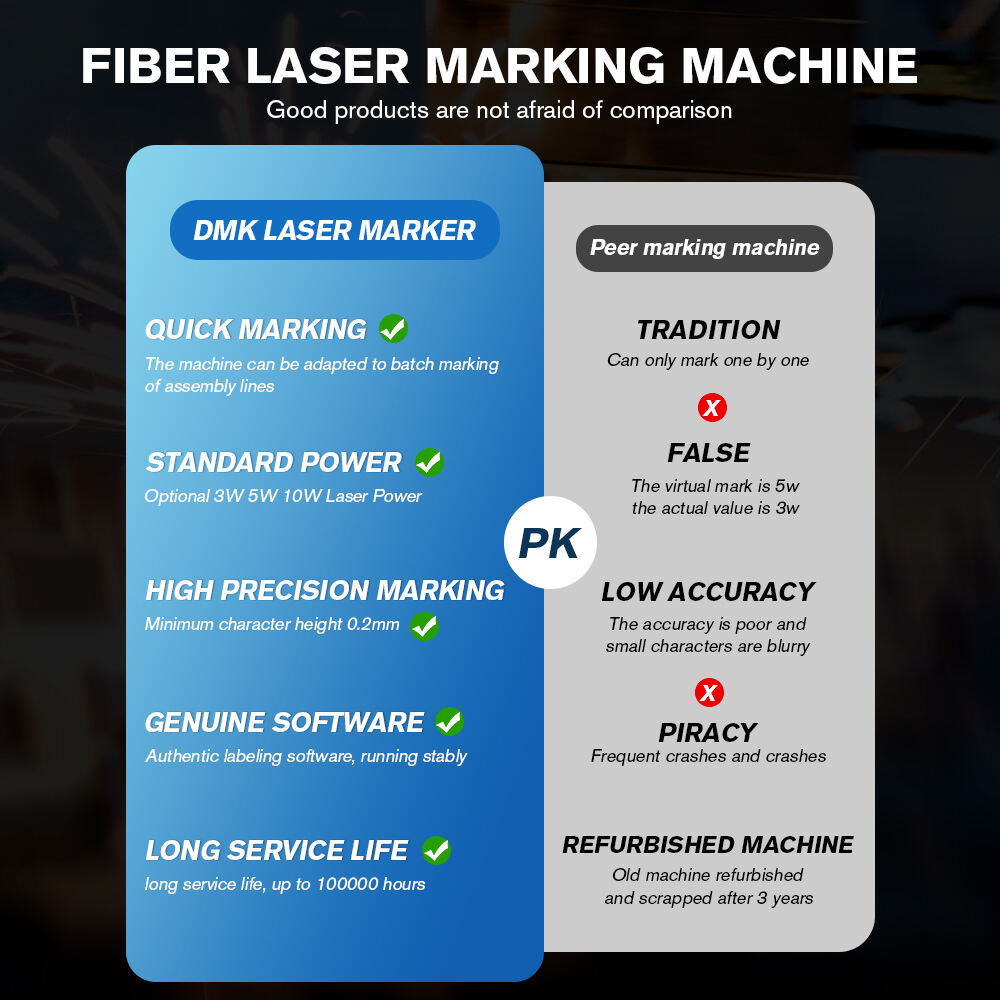

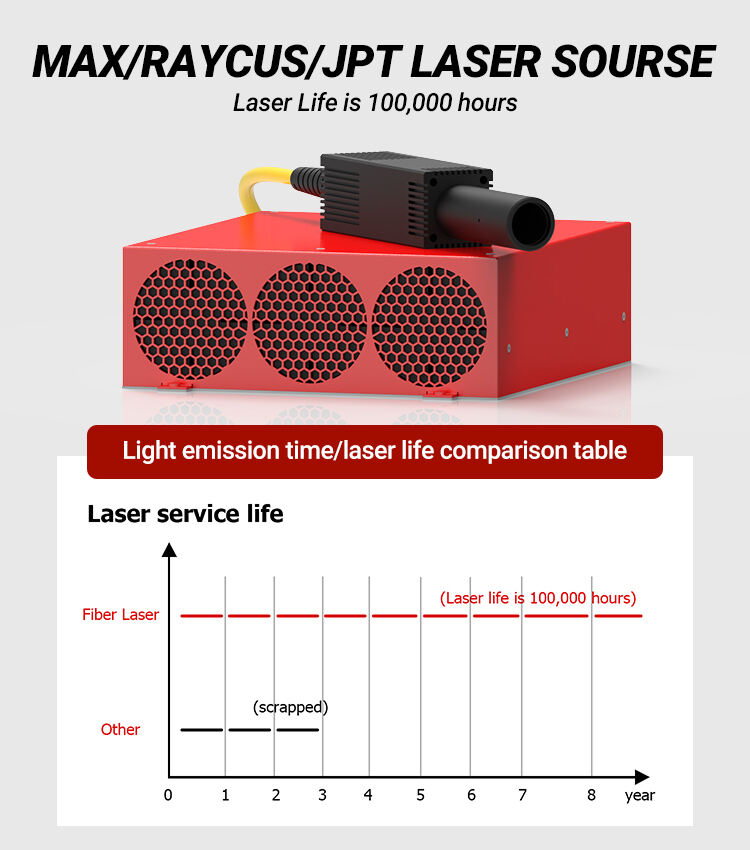

UV Laser Marking Machine is a high-end industrial marking equipment focusing on ultra-fine processing. Adopting pulse duration tunable fiber laser technology, it uses 355nm short-wavelength laser to directly break material molecular chains for permanent marking. Different from the surface evaporation processing of long-wave laser, it has finer marking effect and no material burning problem.

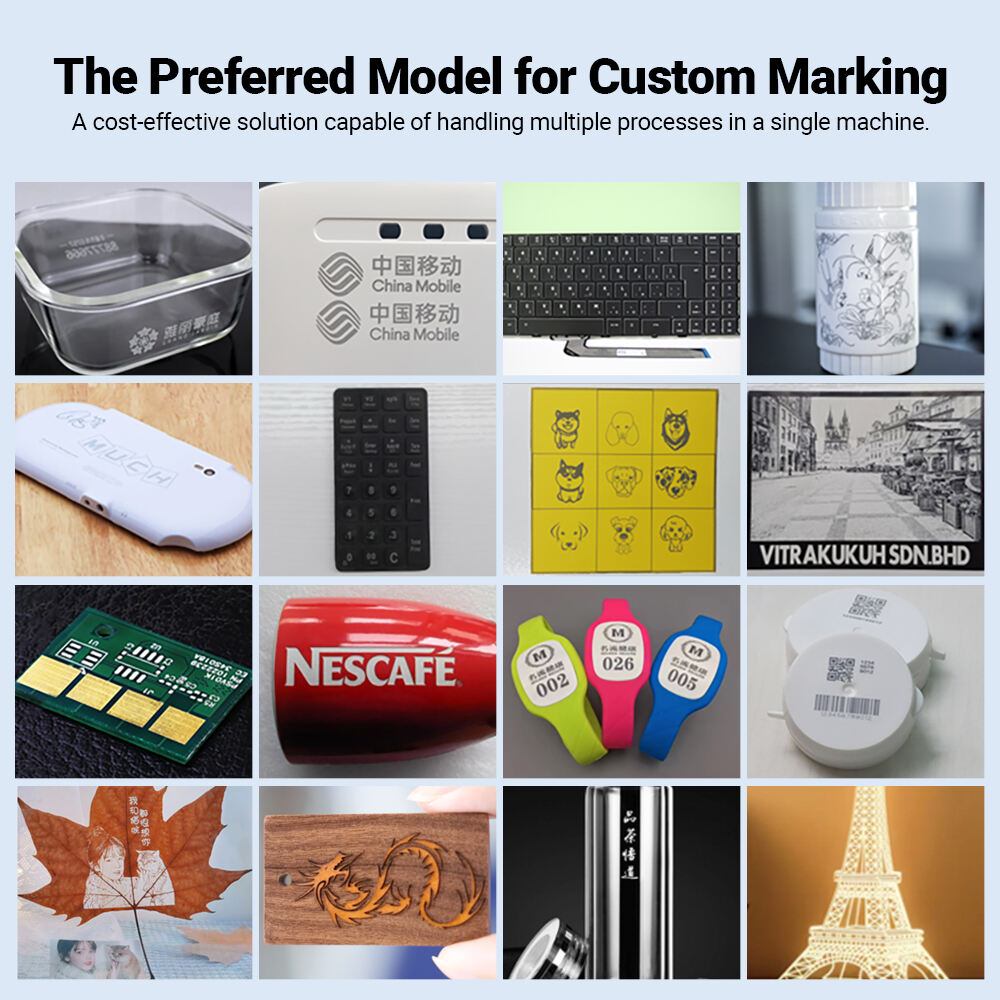

The equipment has core advantages such as excellent beam quality, small focused spot (minimum character height 0.1mm) and extremely small heat-affected zone. Except for copper materials, it is suitable for various materials including wood, plastic, glass, leather and polymer materials. It can accurately mark numbers, characters, QR codes, vector graphics, etc., support importing multiple format files such as AI, BMP, PLT and DXF, with fast marking speed, high efficiency, stable overall performance and low power consumption.

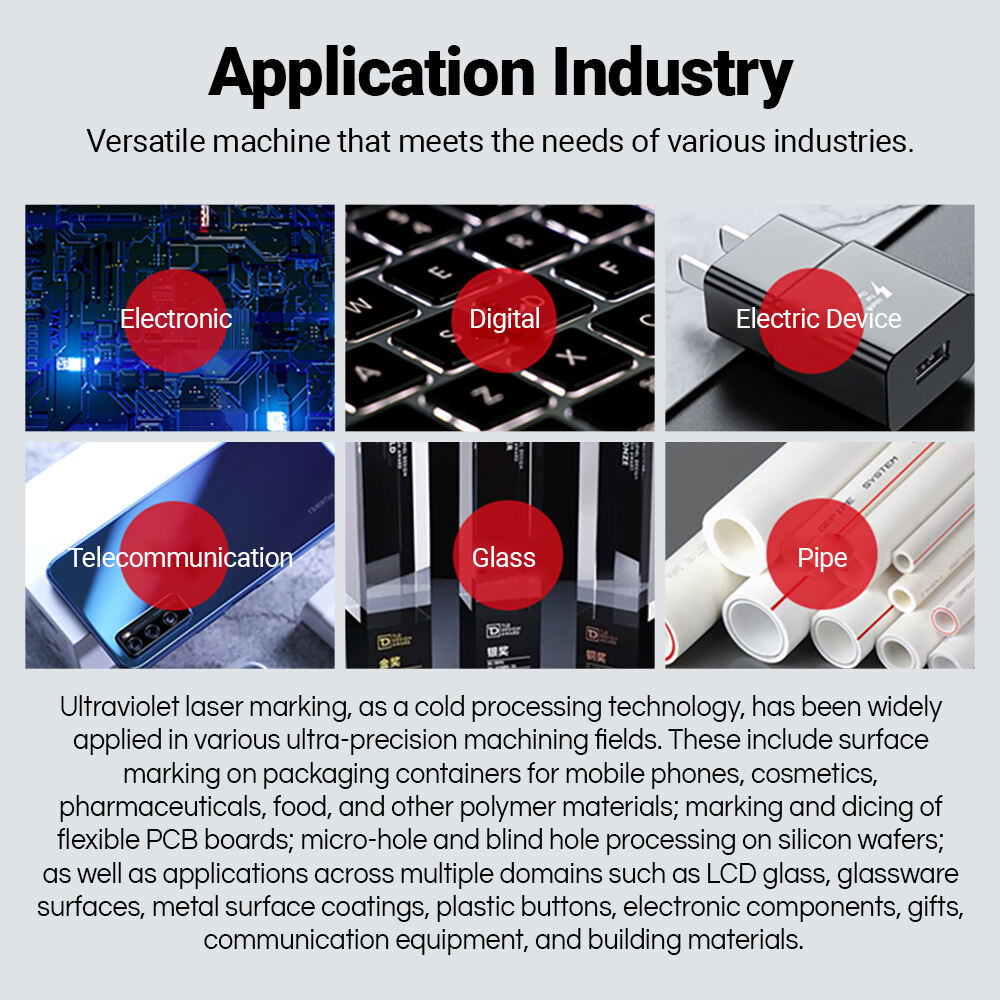

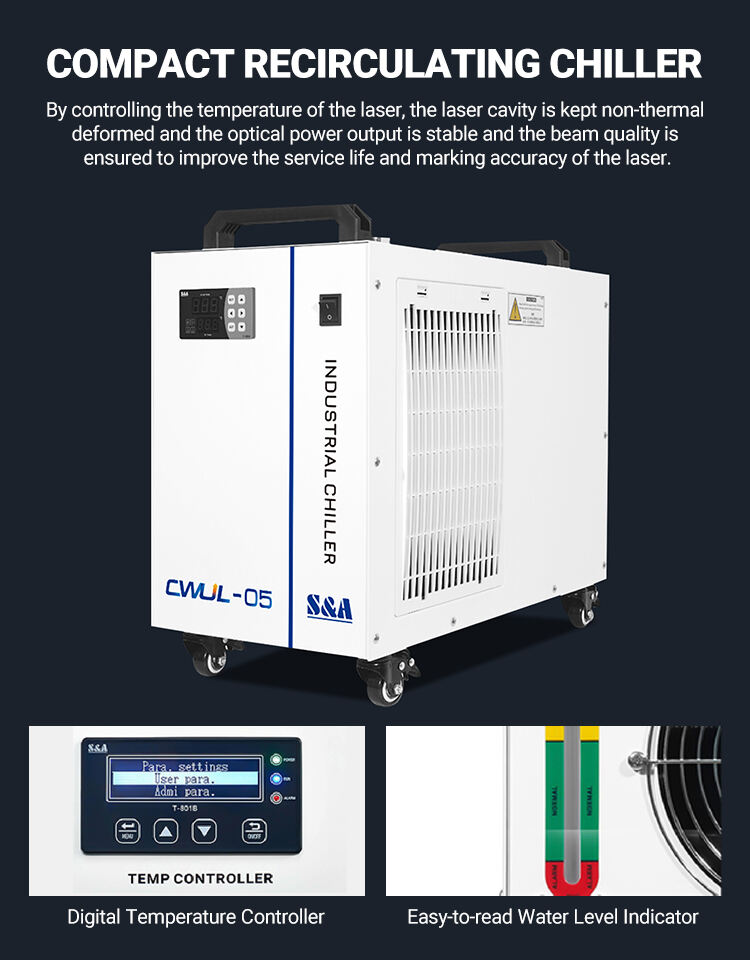

Equipped with a water-cooled cooling system (temperature control accuracy ±0.3℃) to ensure long-term stable operation of the equipment, it is widely used in high-end ultra-fine marking scenarios such as cosmetics packaging, medical packaging, food packaging, flexible PCB marking and dicing, silicon wafer processing, LCD liquid crystal glass QR code marking, electronic components and communication equipment.

Product Parameters

| Parameter Category | Specific Parameters |

|---|---|

| Core Laser Parameters | - Laser Central Wavelength: 355nm - Nominal Average Output Power: 3W/5W/10W/15W/20W/30W - Pulse Repetition Frequency: 10-150kHz - Pulse Width: <20ns@40kHz (DMK-UV3-5); >10ns@60kHz (DMK-UV10), etc. - Beam Quality: ≤1.2 - Average Power Stability (24h): RMS≤3% |

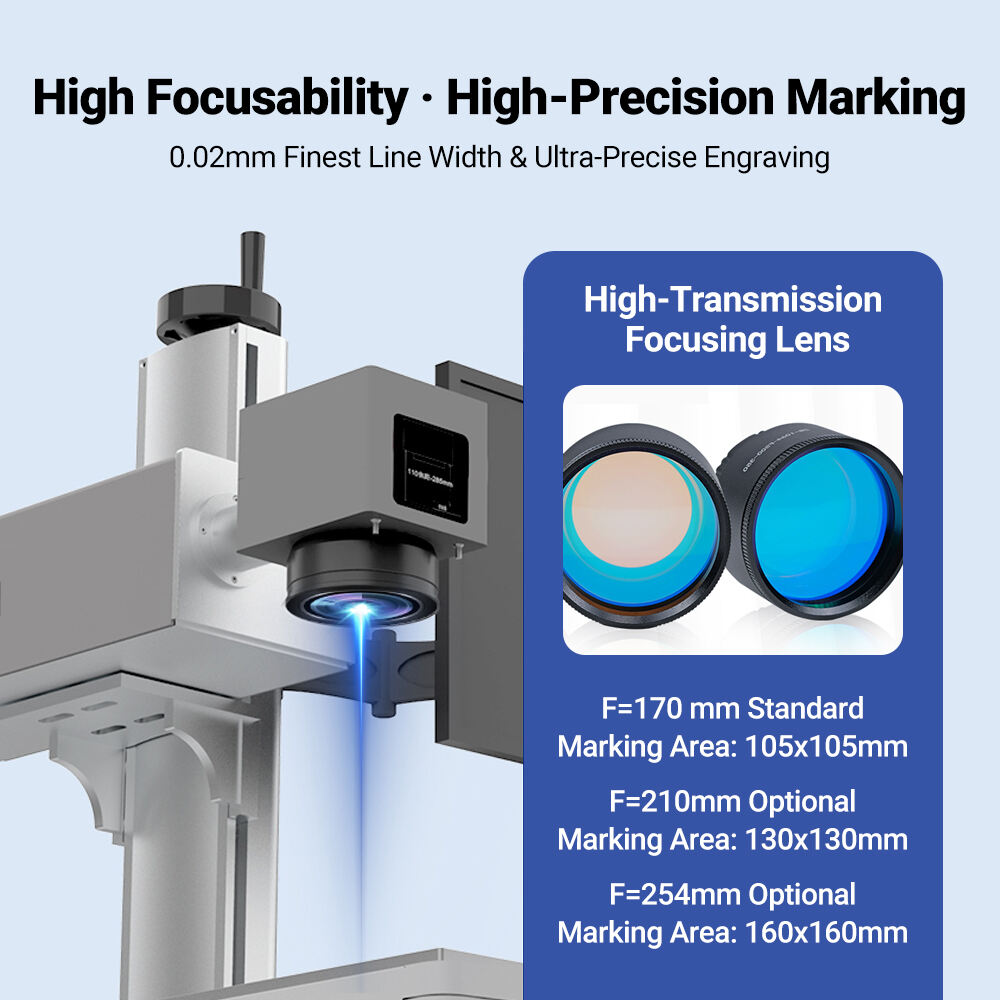

| Optical Output Parameters | - Focus Lens: F=100mm/F=160mm/F=254mm - Marking Range: 70×70mm (Standard)/110×110mm/175×175mm - Standard Line Width: 0.02mm (Material-dependent) @F=160mm - Minimum Character Height: 0.1mm (Material-dependent) @F=160mm |

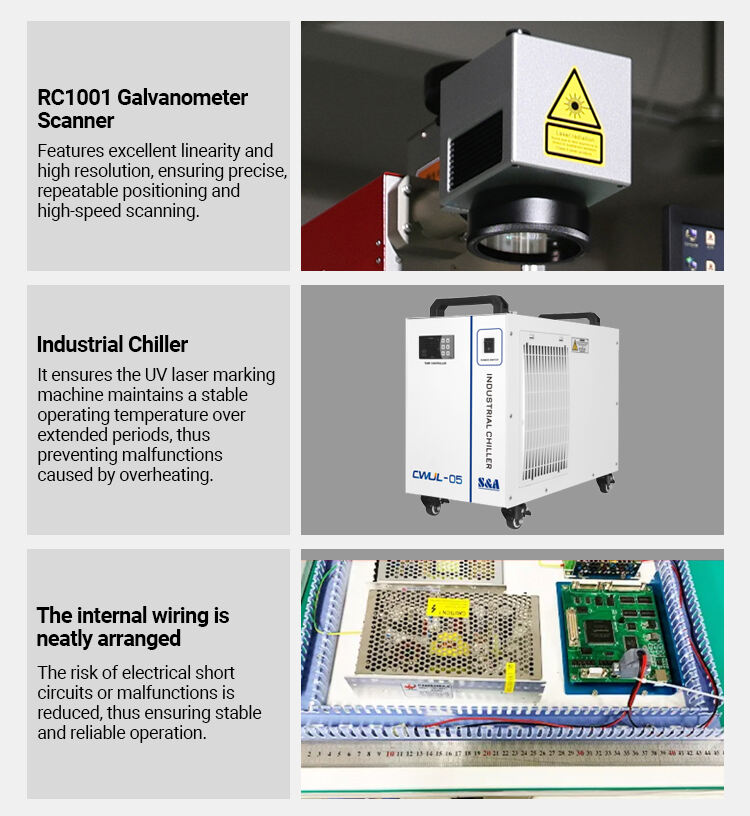

| Galvanometer and Motion Parameters | - Scanning Speed: ≤7000mm/s (F=160mm) |

| Cooling and Power Supply Parameters | - Cooling Mode: Water Cooling (Chiller Cooling Capacity 380W/750W/1400W) - Temperature Control Accuracy: ±0.3℃ - System Power Supply: AC220V/50Hz (Voltage Fluctuation Range ±5%) |

| Operating Environment Parameters | - Ambient Temperature: 0~40℃ - Ambient Humidity: 30%≤RH≤85% (No Condensation) - Grounding Requirement: Comply with national standard power grid grounding requirements |

Other Details

1、Equipment Composition and Operation

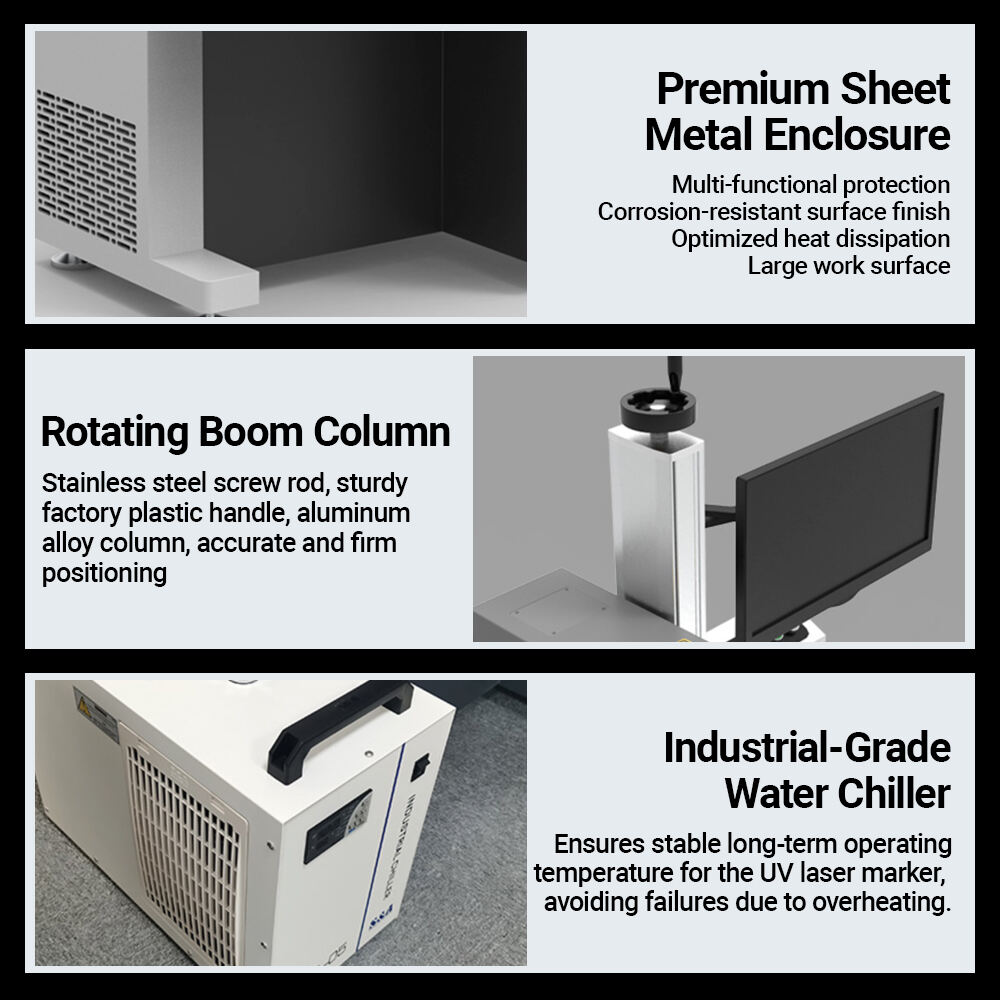

- Core Components: Cabinet Body (built-in laser and electronic control system), Galvanometer Head (controls marking trajectory), Lifting Crank (adjusts focal length, stroke 500mm), Field Lens (focuses laser), Computer (installs marking software), Workbench (places products to be processed), Chiller (cools and dissipates heat).

- Operation Process: Turn on the key switch → Start the computer → Turn on the laser power supply → Turn on the galvanometer power supply → Import design files → Adjust parameters (power, speed, frequency, etc.) → Calibrate focal length → Fix materials → Close the protective door → Start marking.

- Safety Specifications: The equipment is a Class IV laser product. Operators must wear laser protective glasses throughout the operation and are strictly prohibited from looking directly at the laser output head; the laser output head shall not be directed at personnel to avoid radiation damage.

2、Maintenance and Troubleshooting

| Daily Maintenance | Common Troubleshooting |

|---|---|

| - The equipment should be placed in a clean and well-ventilated room with an optimal room temperature of 22-25℃, and kept at least 0.5m away from the wall to ensure heat dissipation. - When dust is generated during processing, use a small fan for dust prevention to avoid lens contamination; wipe the dirty lens gently with lens paper or ethanol. - Regularly clean the equipment air inlet and fan, check the water level and circulation status of the water cooling system, and ensure the water temperature ≤30℃. | - No Power On: Check the power cord connection, whether the 10A fuse is burned out, or whether the start relay inside the control box is damaged. - No Laser Output: Confirm that the laser power supply is energized and the emergency stop switch is reset. - Weak Laser Energy: Replace the aging lens and adjust the workbench to the correct focal length. - No Red Light Indication: Replace the red light emitter or check if the red light switching power supply normally outputs 5V voltage. |

3、Parameter Adjustment Skills

- Power Adjustment: 10%-30% power for shallow engraving (paper, thin plastic); 50%-100% power for deep engraving (hard wood, thick glass).

- Speed Adjustment: High speed (≥3000mm/s) for large-area shallow engraving; low speed (≤1000mm/s) for fine deep engraving.

- Frequency Adjustment: Low frequency (1-20kHz) for deep and thick lines; high frequency (20-50kHz) for delicate surfaces.

- Focal Length Adjustment: Keep the workpiece surface within the focal depth range (1mm-2mm), and calibrate by red light positioning or test marking.

Sample Display

EN

EN

AR

AR CS

CS NL

NL FR

FR DE

DE IT

IT JA

JA KO

KO PL

PL PT

PT RU

RU ES

ES UK

UK TH

TH TR

TR