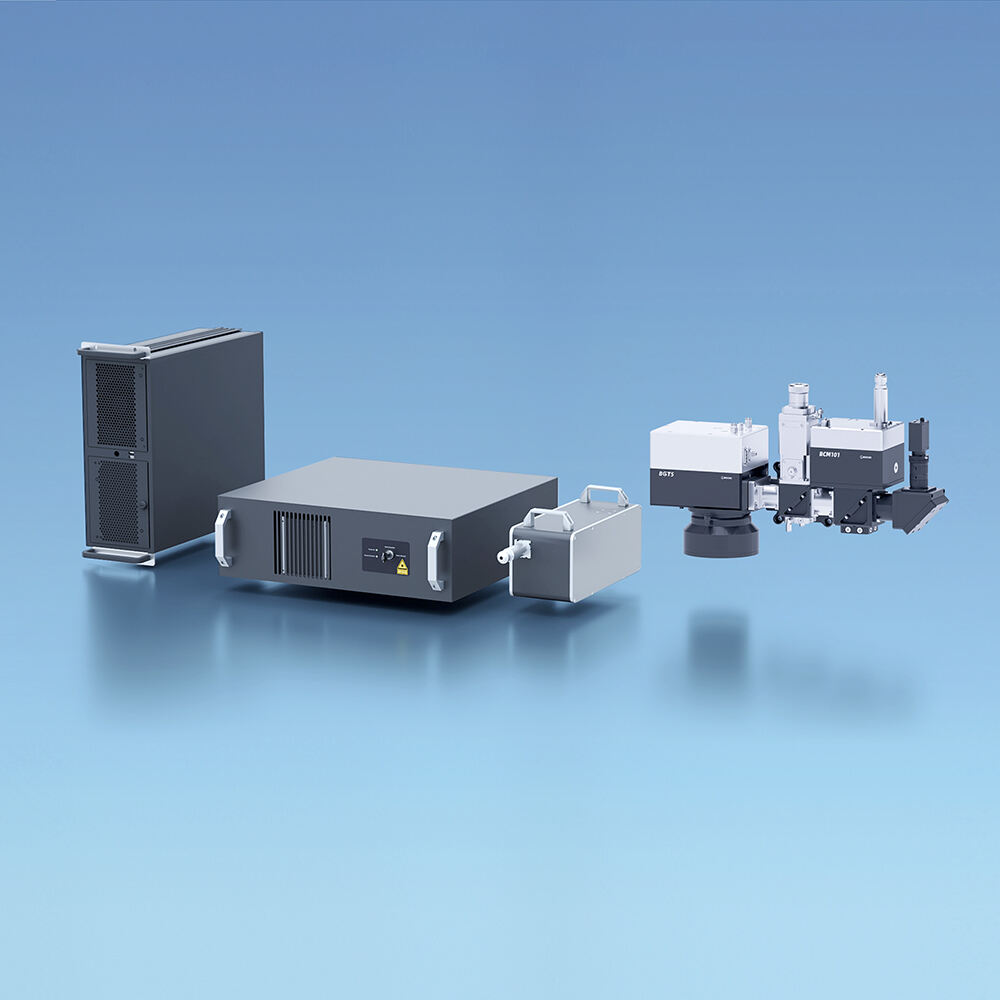

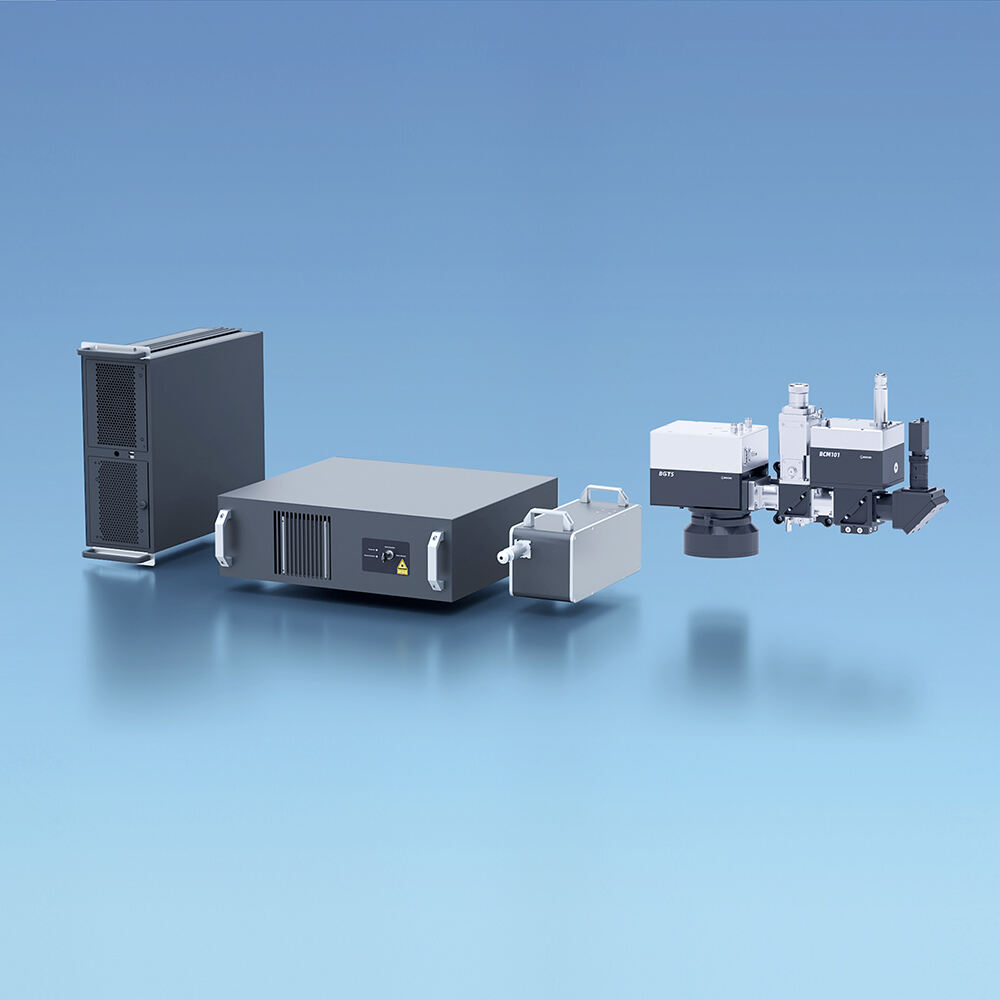

UltraOCT Real-Time Laser Welding Keyhole Depth Monitoring System

Product Description

The Bochu UltraOCT System brings unmatched accuracy to laser welding quality control. Using advanced Optical Coherence Technology (OCT), it measures weld penetration depth in real time — ensuring perfect results for every joint.

With pre-weld, in-weld, and post-weld inspection, UltraOCT delivers 100% process coverage, detecting issues before they become costly defects.

Why Choose UltraOCT?

Smarter Detection: Scans seam gaps, defocus, misalignment, and warping before welding

Live Penetration Monitoring: Instantly spots depth fluctuations, incomplete fusion, and burn-through

Post-Weld Analysis: Measures weld width, roughness, porosity, and undercut

Performance You Can Rely On

5.2× better imaging than conventional OCT

Zero tracking error with ScanForward technology

Chip-level synchronization between welding and detection for ultimate precision

Fully automatic calibration for dispersion, alignment, and optical path difference

Technical Highlights

| Resolution | 12 μm longitudinal, 30–50 μm lateral |

| Max Depth | 6 / 9 / 12 mm |

| Frequency | 80 / 130 / 250 kHz |

| Focal Length | 254–500 mm |

| Lateral Range | ±15 mm |

| Reference Arm Travel | 700 mm |

| Swing Speed | 100 rad/s |

UltraOCT turns laser welding quality from guesswork into certainty — making every weld visible, measurable, and dependable.

EN

EN

AR

AR CS

CS NL

NL FR

FR DE

DE IT

IT JA

JA KO

KO PL

PL PT

PT RU

RU ES

ES UK

UK TH

TH TR

TR