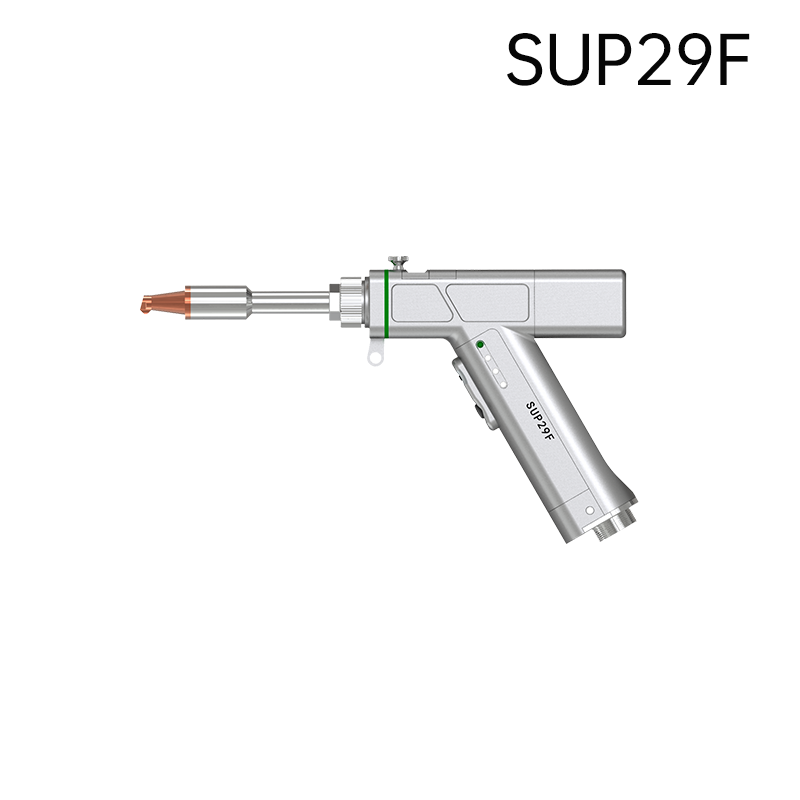

SUP29F 4-in-1 Handheld Laser Welding Head

Product Description

The SUP29F is a 4-in-1 handheld laser welding head specifically designed for low-power scenarios up to 1200W. It is compatible with a laser wavelength of 1070±10nm and adopts convenient air-cooling for heat dissipation, eliminating the need for an external water-cooling system. Weighing only 0.65kg, it features a customized mini QBH lock to optimize weight, ensuring comfortable and flexible handling.

Equipped with an independent gun status light, a self-developed safety detection system, and real-time temperature monitoring, it supports four integrated functions: handheld continuous welding, spot welding, cleaning, and cutting. It also allows one-click switching between 3 sets of preset processes. Core components like lenses and QBH locks are designed for plug-and-play replacement. Balancing safety, portability, and versatility, this welding head is an ideal choice for low-power laser processing scenarios.

Product Features

- Safety - Perfectly safe:Gun body independent status light, self-developed safety detection system, built-in real-time temperature monitoring

- Time saving - Efficient and Convenient:Independent process switch button, easy to switch 3 preset processes; Focusing lens, protection lens drawer, collimating lens and QBH lock integrated, pluggable, easy to replace on site

- Lightness - Light and Convenient:Customized mini QBH lock,optimize the weight of the entire gun; Comfortable grip, flexible operation, easy to use

- Quality - Beautiful welding - Stable performance:Built-in digital driver, strong anti-interference performance, stable and reliable; The optical structure is further optimized, the welding strength is high, the deformation is small, the melting depth is high

- Performance - Multiple functions:Support handheld continuous welding, spot welding, cleaning, cutting, "hand" self-integration, password authorization, real-time monitoring of all interfaces, convenient on-site maintenance, remote support

Technical Parameters

Scope of application |

≤1200 W |

Protective lens |

D18*T2mm |

Collimating tens |

D16 F50 mm |

Vertical focusing range |

±10mm |

Focusing lens |

D20 F150 mm |

Light spot adjustment range |

Line 0-8mm |

Applicable wavelength |

1070±10mm |

Recommended flow |

10-15L/min |

Weight |

0.65Kg |

Type of cooling |

Air cooling |

Application

- New Energy Vehicle Sector: Suitable for on-site repair of aluminum battery pack casings. Its pulsed laser can precisely control the heat-affected zone, avoid electrode wear issues associated with traditional TIG welding, and improve welding efficiency and yield rate.

- Precision Electronics Industry: Applicable to the assembly of precision components such as TWS earphone magnetic charging modules. With a spot diameter as small as 0.1mm, it enables micro-level welding. Combined with a real-time temperature feedback system, it effectively protects internal precision chips.

- Medical Device Manufacturing: Usable for aseptic welding of medical devices like titanium alloy orthopedic implants. The enclosed air-cooling system eliminates metal spatter contamination caused by traditional welding, ensuring welding quality and the safety of medical devices.

- Architectural Decoration Industry: Capable of outdoor welding operations such as stainless steel curtain walls. Equipped with a lithium battery module power supply solution and an intelligent wire feeding mechanism, it is not restricted by power sources, which improves welding efficiency for high-altitude operations. It can also complete seamless welding of special-shaped steel structure artistic joints, ensuring both aesthetics and structural strength.

- Sheet Metal Processing Industry: Widely used in the welding of sheet metal products such as kitchen cabinets, stairs, elevators, shelves, and distribution boxes. It can weld various complex and irregular weld seams, featuring fast welding speed, smooth and aesthetically pleasing welds without cracks or welding scars, and reduces subsequent processing steps like polishing.

EN

EN

AR

AR CS

CS NL

NL FR

FR DE

DE IT

IT JA

JA KO

KO PL

PL PT

PT RU

RU ES

ES UK

UK TH

TH TR

TR