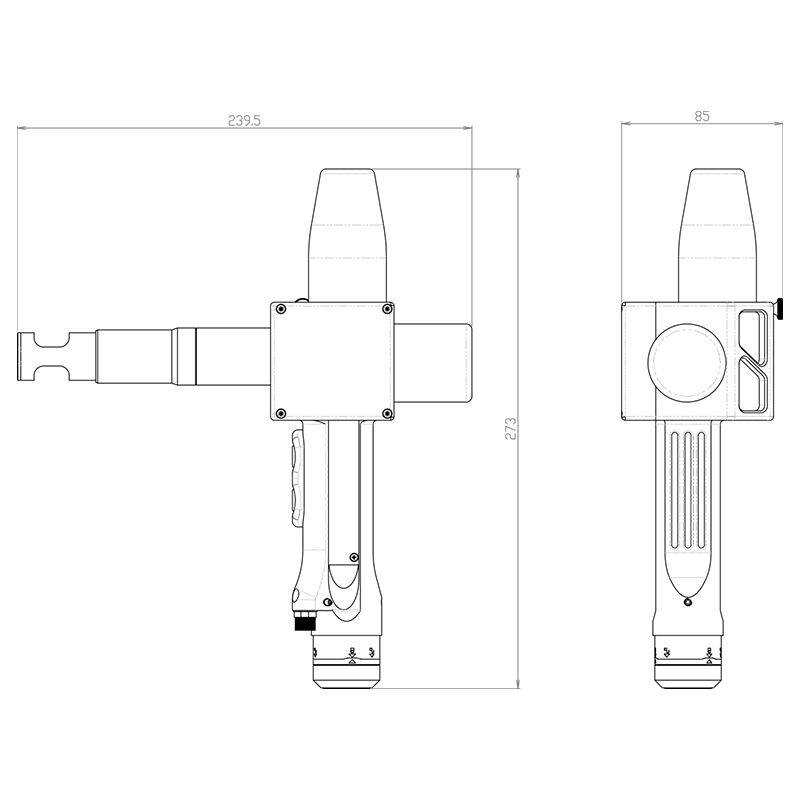

SUP27S 4 in 1 Handheld Laser Swing Welding Head

Product Description

The SUP27S 4 in 1 Handheld Laser Welding Head is specifically designed for power scenarios up to 3000W, compatible with a laser wavelength of 1070±10nm, and adopts water-cooling for heat dissipation to ensure stable operation. It is equipped with an independent safety switch and a self-developed safety monitoring system that real-time monitors interface signals and laser head temperature.

Featuring an ergonomic structure for two-handed holding and a drawer-type lens design, it is compatible with various focusing lenses and welding environments-especially suitable for welding R&D needs in the new energy field. It is a handheld laser welding device that balances safety and professionalism.

Product Features

- Safety - Perfectly safe:Add safety switch for safer use;The independently developed safety monitoring system monitors the real-time status of various interface signals and the temperature status of the laser head

- Function - Specialized and Unique:Designed for welding research and development in the field of new energy, can meet a variety of weld needs; Stable welding and accurate trajectory. Suitable for a variety of focusing mirrors, can be adapted to different welding environment

- Design - Innovation for Change:Ergonomic support structure, easy to hold with both hands, easier to weld; Simple operation, easy to use

- Maintenance - Simple and Convenient:Drawer style lenses are convenient for on-site replacement

Technical Parameters

Scope of application |

≤3000W |

Protective lens |

D30 T3mm |

Collimating tens |

D16 F60 mm |

Vertical focusing range |

±10mm |

Focusing lens |

D30 F150 mm |

Maximum spot |

15mm |

Applicable wavelength |

1070±10mm |

Recommended flow |

10-15L/min |

Weight |

1.1Kg |

Type of cooling |

Watercooling |

Application

- Welding of new energy battery components ( tabs, cell casings)

- Welding of new energy vehicle metal accessories (connectors, small brackets)

- Oscillating welding of medium-power metal workpieces (stainless steel, aluminum alloy components)

- Welding scenarios requiring precise trajectory control (precision metal structural parts)

EN

EN

AR

AR CS

CS NL

NL FR

FR DE

DE IT

IT JA

JA KO

KO PL

PL PT

PT RU

RU ES

ES UK

UK TH

TH TR

TR