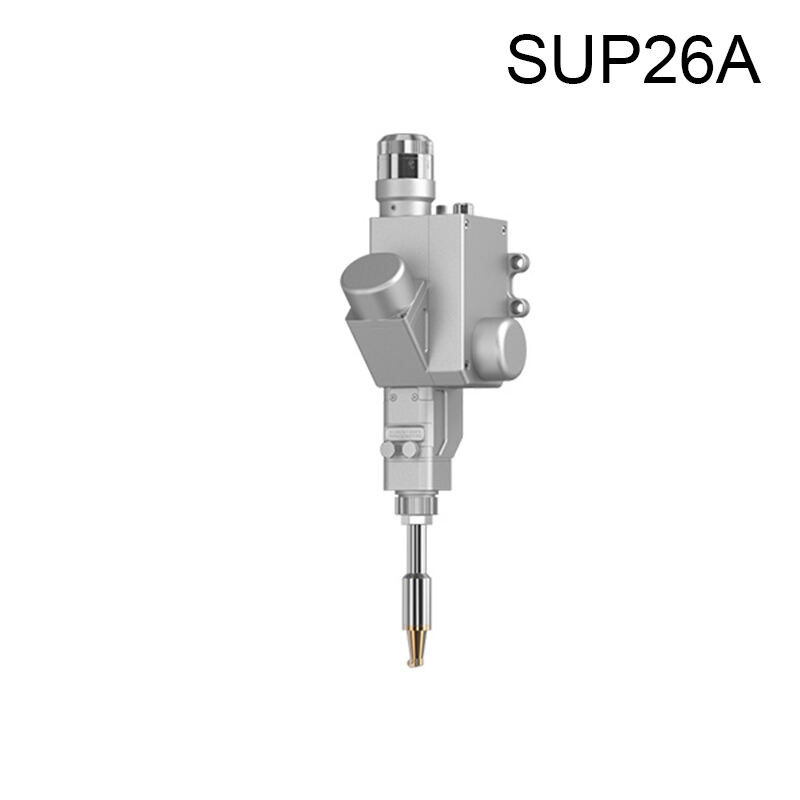

SUP 26A Optical Fiber Oscillating Welding Head

Product Description

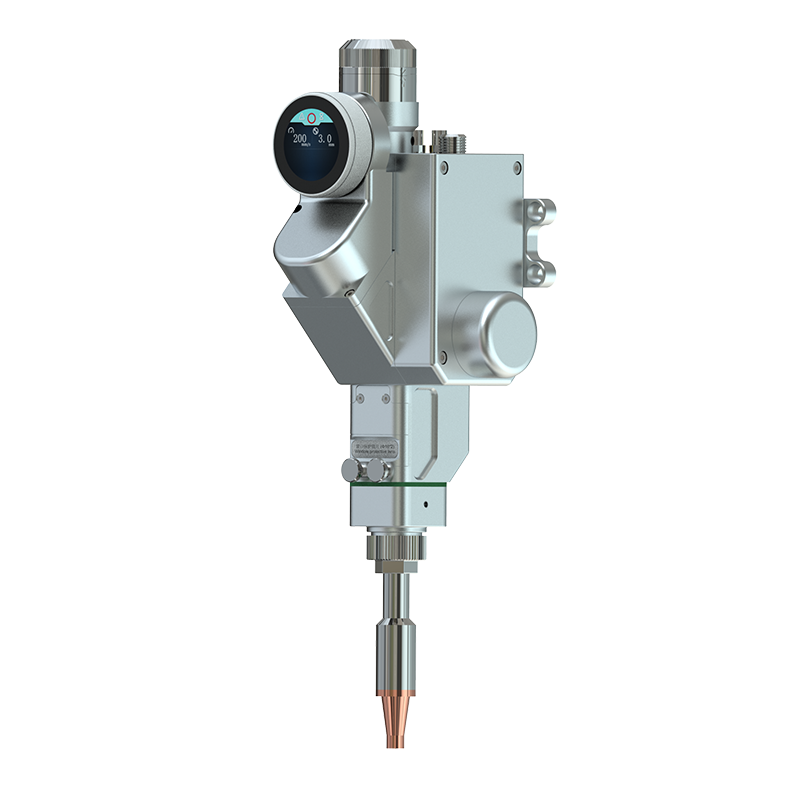

The SUP 26A Optical Fiber Oscillating Welding Head is a cost-effective automated welding tool engineered for power capacities up to 3000W. Its space-saving, lightweight build (a mere 1.2kg) fits seamlessly into mainstream laser setups while alleviating mechanical strain on machine tools. Boasting a fully sealed inner structure to fend off dust, it incorporates a transparent water-cooling system for steady long-term performance. A galvanometer motor drives X/Y axis lens oscillation across multiple modes. Compatible with the QBH interface and lasers from manufacturers such as IPG, Raycus, and JPT, it delivers superior results in rapid, high-precision automated welding operations.

Product Features

- Superior Dust Resistance & Budget-Friendly Design:As an optical fiber swing welding head, it delivers fast, high-precision welding. Its fully sealed internal structure keeps optical components free from dust contamination, giving it a distinct edge in automated welding scenarios. This makes it an economical choice for medium-power the equipment.

- Consistent Quality & Flexible Oscillation Modes:A galvanometer motor drives X/Y axis lenses to swing with multiple modes, enabling swing welding to handle irregular workpiece joints and larger gaps-greatly enhancing weld quality. It also supports wire breakage detection and dynamic parameter adjustment for continuous laser output, ensuring reliable performance.

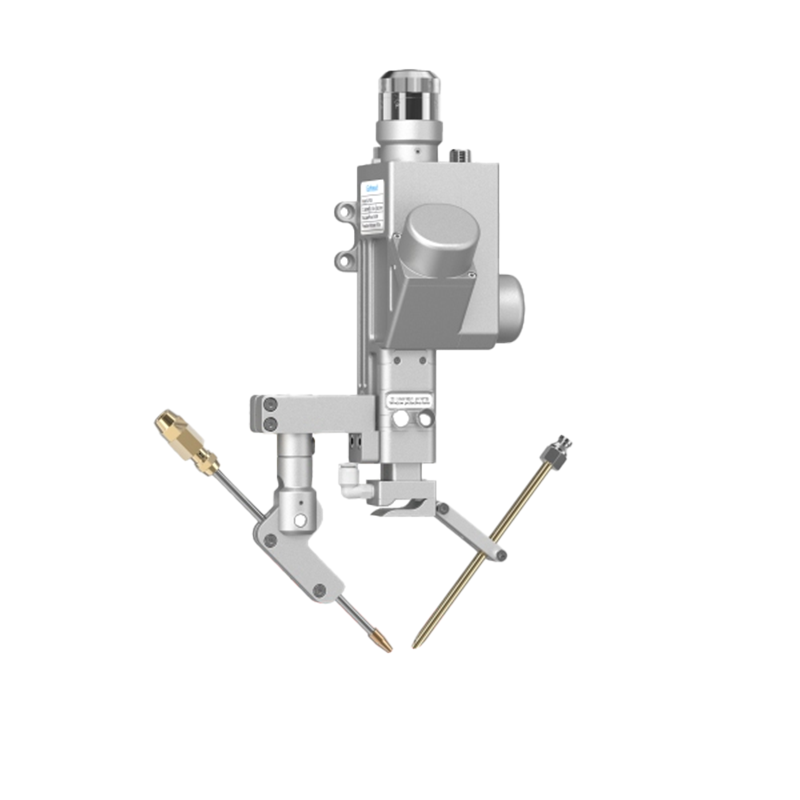

- Precision Welding & Hassle-Free Maintenance:The sealed structure reduces lens pollution from welding fumes and spatter. Both protective and focusing lenses feature a drawer-style design for quick on-site replacement, and it supports switching between D20 F150/F200mm focusing lenses, simplifying upkeep and adapting to diverse welding demands.

- Wide Compatibility & Easy Integration:Fitted with a QBH interface, it works seamlessly with lasers from brands like IPG, SPI, Ronfin, nLight, Raycus, Chuangxin, Tottenham, Keplin, JPT, and Guanghui-no extra modifications needed, making integration with existing systems straightforward.

- Lightweight Build & Efficient Cooling:With a compact structure weighing just 1.2kg, it eases mechanical load on machine tools to boost operational efficiency. The integrated transparent water-cooling system dissipates heat effectively, ensuring stable long-term operation even at maximum power (≤3000W).

Technical Parameters

Scope of application |

≤3000 W |

Focusing lenses |

D20 F150/F200mm |

Collimator |

D16 F60mm |

Focus vertical mediation |

±10mm |

Protective mirror |

D18*2mm |

Recommended flow |

10-15L/min |

Weight |

1.2Kg |

Type of cooling |

Water cooling |

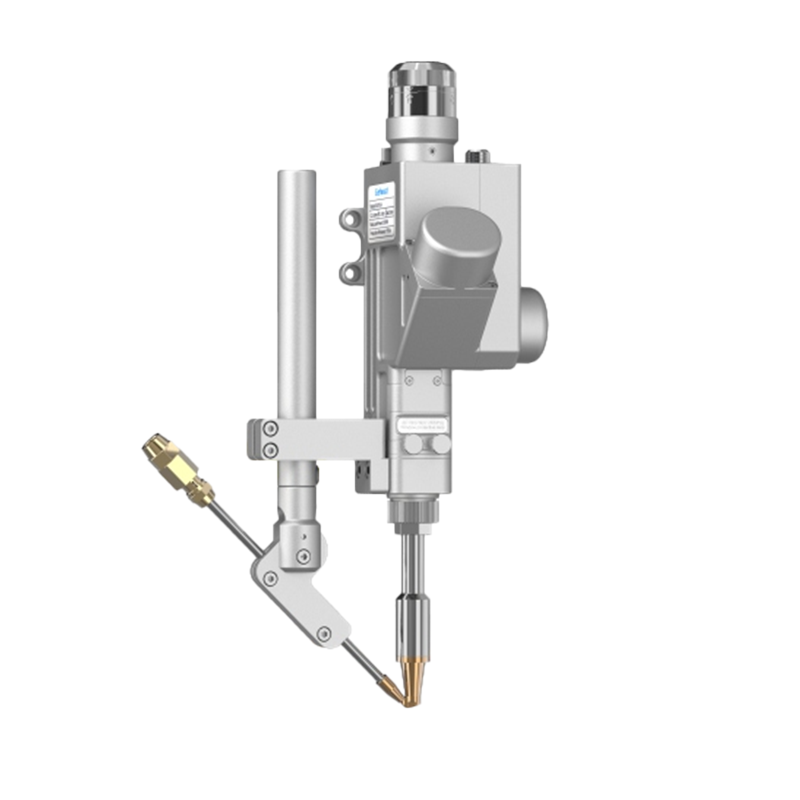

Application

|

|

| Robotic laser welding | Automated laser welding |

EN

EN

AR

AR CS

CS NL

NL FR

FR DE

DE IT

IT JA

JA KO

KO PL

PL PT

PT RU

RU ES

ES UK

UK TH

TH TR

TR