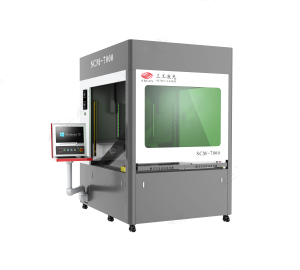

SUNICLASER Ultra-fast Denim Laser Burnishing Machine

Product Description

This ultra-fast denim laser burnishing machine is a professional processing equipment designed specifically for denim fabrics. It is equipped with denim-specific software and original imported core components, supporting multiple power options ranging from 350W to 700W.

The machine can achieve various denim processes such as whiskers, monkey wash, sanding, holes, burnishing, and hanging grinding. It has a marking range of 900×900mm~1400×1400mm and a marking speed of up to 15000mm/s. By replacing traditional water-washing processes with laser technology, it balances environmental protection and efficiency, making it suitable for batch processing needs of various denim fabrics.

Details Display

Product Features

- Full Process Coverage + Dedicated Software:As an ultra-fast denim laser burnishing machine, it has built-in denim-specific software to complete whiskers, monkey wash, sanding, holes, burnishing and hanging grinding in one stop (no extra equipment needed). It supports bitmap/vector engraving, with one-click generation of complex burnishing effects to simplify denim laser processing workflow.

- High Power + Ultra-High Speed:It offers 3 power models (SCM-4000/350W, SCM-5000/400W, SCM-7000/700W) for different denim fabrics. With max marking speed of 15000mm/s, plus electrically liftable laser head and adjustable processing width, it handles large-sized denim quickly, outperforming traditional equipment.

- Precise Positioning + Eco-Friendly Processing:Equipped with high-definition projector positioning (optional cross red light), it enables accurate control. Laser tech replaces traditional water-washing to solve sewage issues; upgraded workbench adsorption/auxiliary air blowing (with optional smoke purifier) reduces dust and smoke.

- Imported Components + Intelligent Design:It uses original imported lasers, galvanometer control systems and lenses for stable performance. Electrically adjusted laser head focal length (digital display) ensures easy operation; optional safety light curtains enhance safety and lower operation difficulty.

- Comprehensive After-Sales Support:Pre-sales: process solutions, technical consultation, sample testing. After-sales: free installation/commissioning (1-2 days) and operator training. National offices and after-sales call center with resident technicians ensure quick maintenance response.

Technical Parameters

Parameter Name |

SCM-4000 |

SCM-5000 |

SCM-7000 |

Laser Power |

350W |

400W |

700W |

Laser Wavelength |

10.6um |

||

Laser Repetition Frequency |

1kHz~100kHz |

||

Marking Range |

900×900mm~1400×1400mm |

||

Marking Speed |

≤15000mm/s |

||

Cooling Method |

Circulating Water Cooling |

||

Working Power Supply |

AC220V/AC380V 50Hz/60HZ |

||

Maximum Power Consumption |

9KVA |

12KVA |

16KVA |

Machine Dimensions |

1900×2640×2560mm (Cantilever Extended) / 1900×1700×2560mm (Excluding Cantilever) |

||

Machine Weight |

Approximately 1250KG |

||

Safety & Environmental Protection Configuration |

Optional Safety Light Curtain, Smoke Purifier |

||

Application

- Laser burnishing on denim garment fabrics: whisker effect on jeans, pattern burnishing on denim jackets

- Processing of denim accessories: hole treatment on denim bags, sanding process on denim hats

- Batch cutting of denim fabrics: special-shaped cutting of denim fabrics, decorative hollowing

- Custom denim processes: monkey wash effect on personalized denim items, bitmap pattern engraving

EN

EN

AR

AR CS

CS NL

NL FR

FR DE

DE IT

IT JA

JA KO

KO PL

PL PT

PT RU

RU ES

ES UK

UK TH

TH TR

TR