Rolling suitcase cleaning equipment

Product Description

Product Brief Introduction

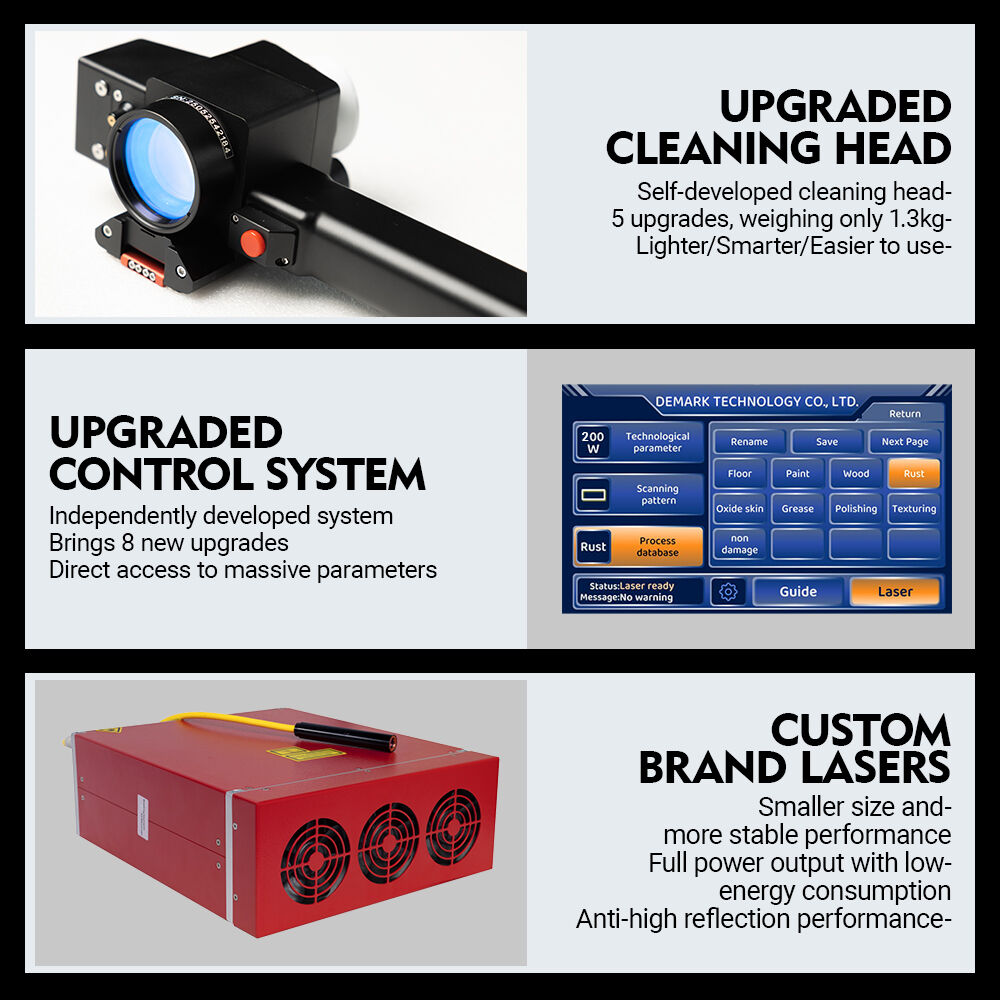

The laser cleaning equipment is a new type of industrial cleaning device. It adopts peak power pulse laser, high-speed scanning system and high-precision control system. The internal electrical components are selected from well-known enterprise brands, featuring stable and reliable performance, excellent quality, super portability, high efficiency and cost-effectiveness.

Cleaning Principle

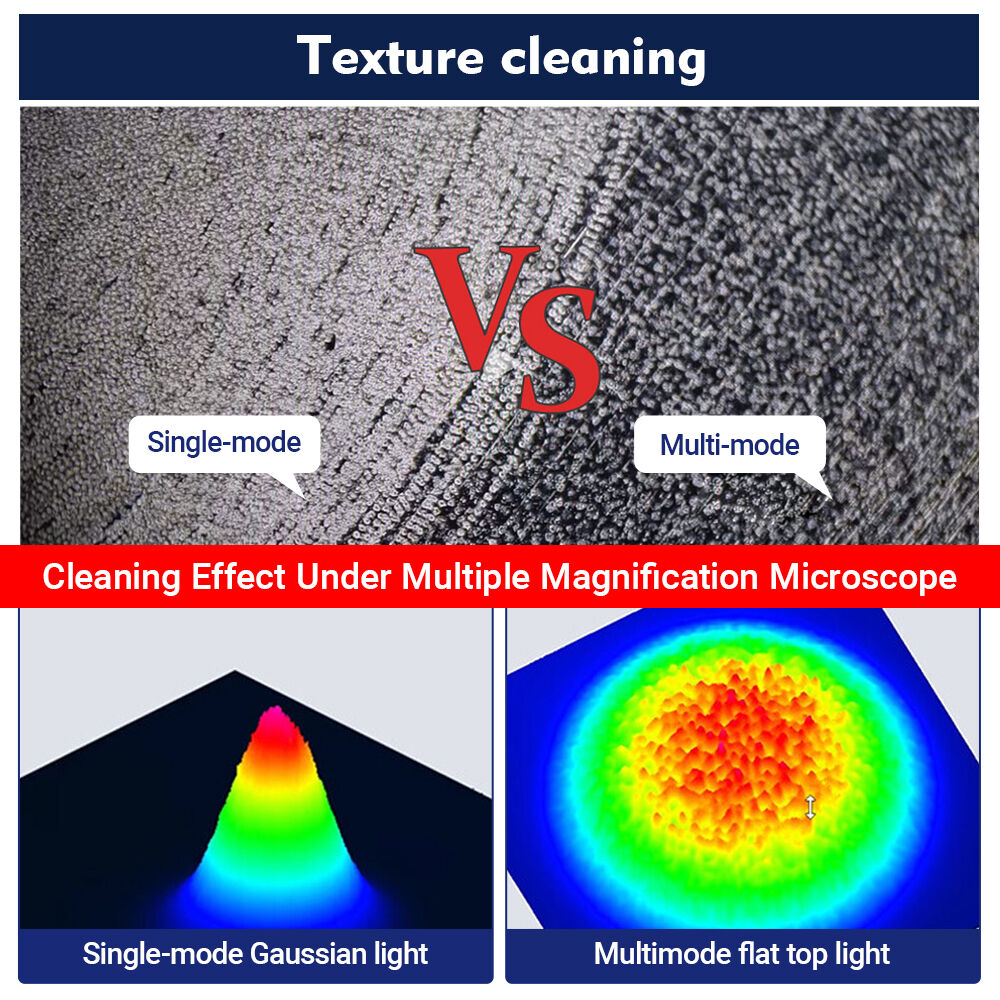

Taking advantage of the difference in laser absorptivity between pollutants and substrates, or the certain difference in melting point and boiling point temperature between the two. After pollutants absorb laser energy, they instantly vaporize, vibrate and expand, and finally peel off from the substrate surface to achieve the cleaning purpose.

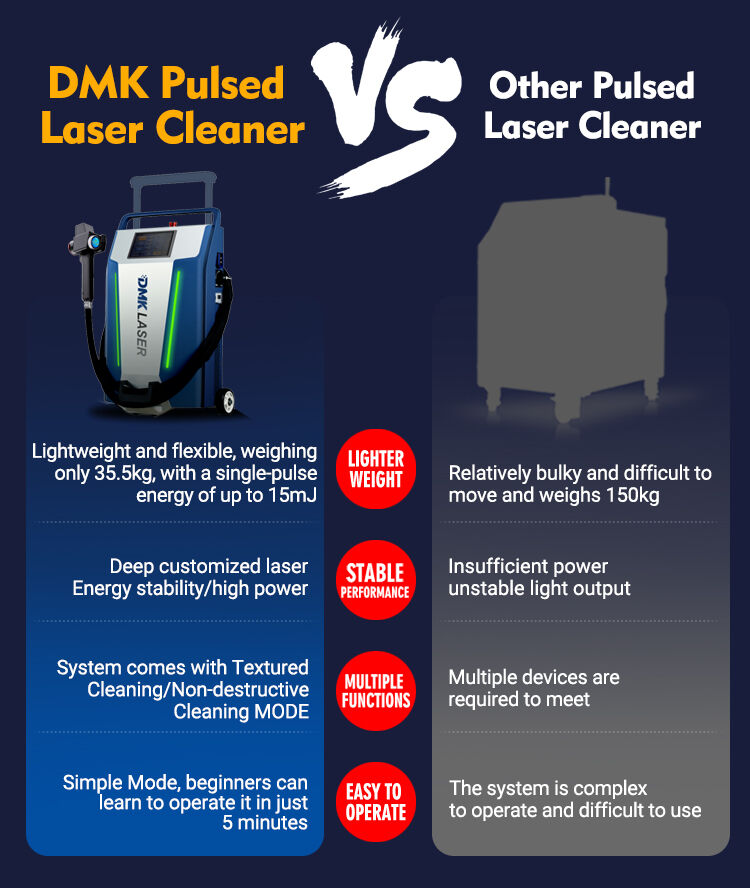

Product Advantages

- Safe and environmentally friendly: Non-contact cleaning without damaging the substrate; no secondary pollution, and the removed substances can be recycled.

- Accurate and controllable: Selective cleaning is available, and micron-level precision control can be achieved in the thickness direction.

- High cost-effectiveness: No consumables are required during use, only electricity is consumed.

- Strong applicability: Hand-held operation, integrable with automation; easy to move and suitable for complex working conditions.

Usage and Characteristics

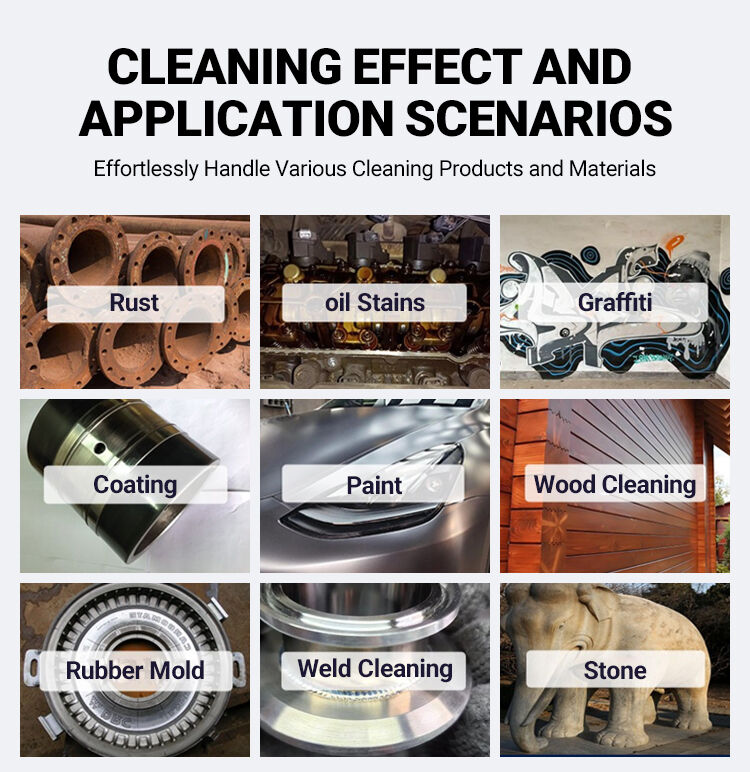

- Usage: It can remove rust, paint and oil stains on metal and some non-metal surfaces, as well as black ash, carbon deposition and oil stains on the surface of parts after welding.

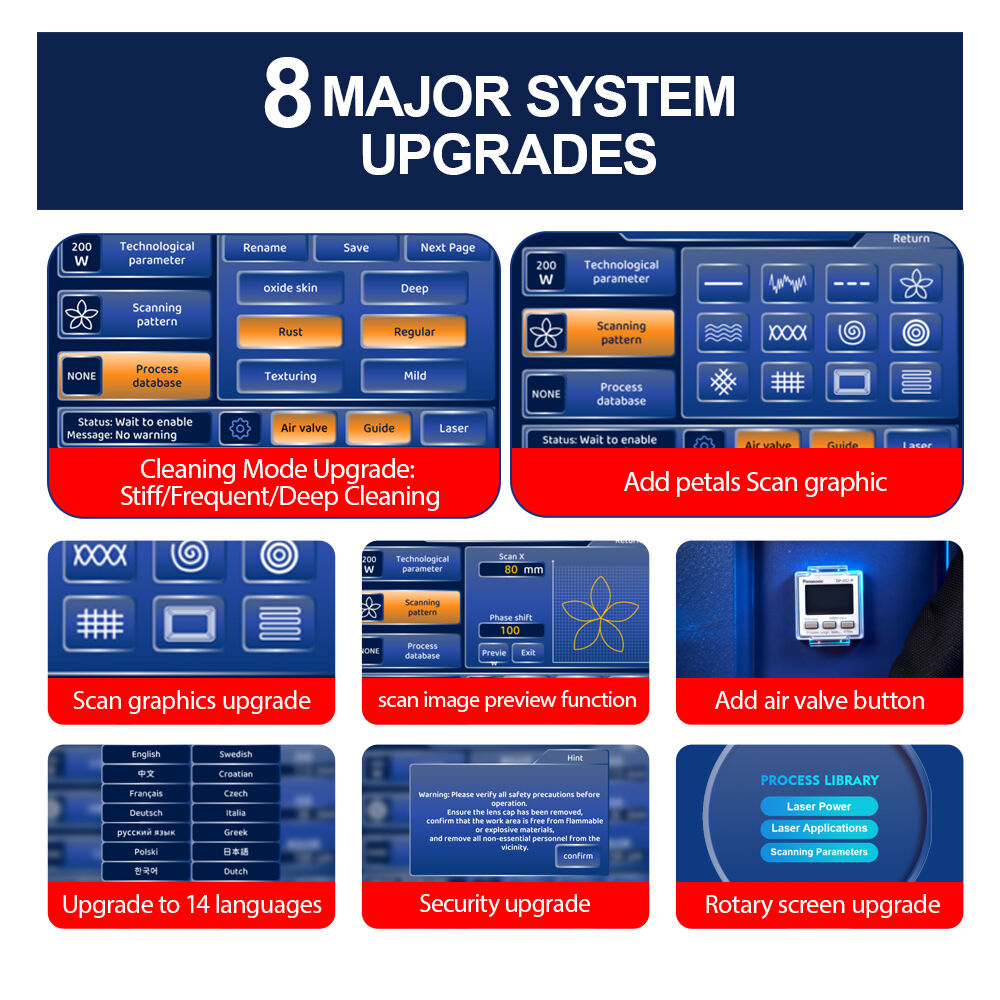

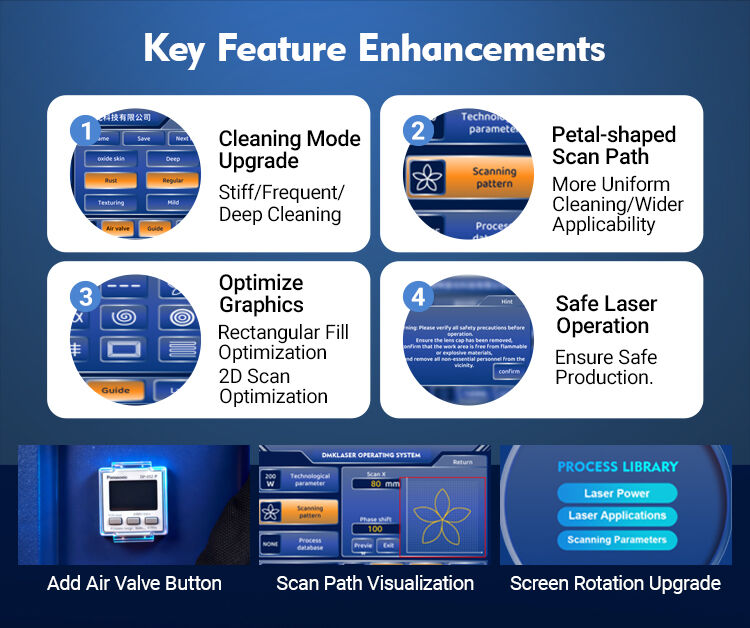

- Characteristics: The net weight of the whole machine is 35.5kg, and the hand-held head is only 1.1kg, which is lightweight and easy to carry; equipped with universal wheels for convenient equipment movement; multiple scanning graphics are preset to ensure the cleaning effect under complex working conditions.

Scope of Application

Applicable to aerospace, rail transit, automobile manufacturing, marine ships, electronic micro-processing, food processing, stainless steel and aluminum alloy products, mold processing and other fields. Typical application scenarios include: cleaning of natural oxide film before aluminum alloy welding, cleaning of black ash oxide after welding of battery trays, cleaning before welding flaw detection of train bogies, cleaning before renovation of automobile sheet metal parts, cleaning of steel wire brushes in small holes and grooves, etc.

Product Parameters

General Characteristic Parameters

Cleaning Head Technical Parameters

Other Details

EN

EN

AR

AR CS

CS NL

NL FR

FR DE

DE IT

IT JA

JA KO

KO PL

PL PT

PT RU

RU ES

ES UK

UK TH

TH TR

TR