SLC-1500/2000/3000 High-Power Laser Cleaning Equipment - 1500-3000W Adjustable + Water-Cooled Design + 10m Fiber + Automated/Handheld Dual Modes - For Aerospace/Rail Transit/Industrial Heavy Pollution Cleaning

Product Description

SLC-1500/2000/3000 is a high-power laser cleaning equipment developed for industrial heavy pollution cleaning scenarios. It adopts high peak power pulsed laser, high-speed scanning system, self-developed high-precision control system and power supply from well-known domestic enterprises, ensuring stable and reliable operation, excellent performance, high efficiency and cost-effectiveness.

The equipment can efficiently realize rust removal, paint stripping, oil removal and oxide film cleaning on all metal and some non-metallic surfaces, as well as the cleaning of black ash, carbon oil and other dirt on component surfaces after welding. Compared with traditional cleaning methods, this industrial laser cleaning machine has prominent advantages: non-contact cleaning without damaging substrates, environmental protection without secondary pollution (recyclable removed substances), micron-level precision control in thickness direction, no consumables during use (only consuming electricity), ultra-energy-saving and strong applicability.

With a net weight of 170-190kg and universal wheels for easy movement, it supports handheld operation or customized integration into robots, CNC and other motion mechanisms. Adopting deionized water cooling, it can operate stably for a long time, and is widely used in aerospace, rail transit, automotive manufacturing, marine vessels, mold processing, electronic microprocessing, food processing, stainless steel and aluminum alloy products and other fields, making it an ideal choice for industrial heavy pollution cleaning.

Product Parameters

| Parameter Category | English Specific Parameters |

|---|---|

| Optical Property Parameters | - Cleaning Head Model: Type A - Laser Average Power: 1500W/2000W/3000W - Power Adjustable Range: 10%~100% - Polarization Direction: Arbitrary - Laser Line Width: 5mm~200mm Adjustable - Fiber Length: 10m - Minimum Fiber Bend Radius: 200mm - Cooling Mode: Water Cooling (deionized water) - Guided Laser Function: Available - Anti-high-reflection Function: Available - Field Lens Model: F210/F254/F330 (Optimized according to actual working conditions) |

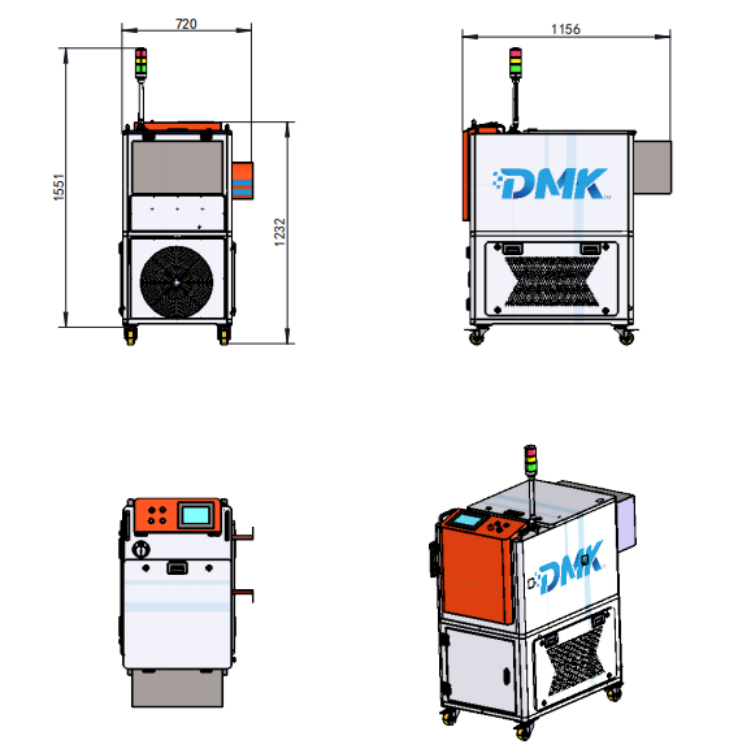

| General Property Parameters | - Chassis Size: L1360mm×W630mm×H1600mm (Subject to actual delivery) - Main Unit Net Weight: 170kg (SLC-1500/2000); 190kg (SLC-3000) - Cleaning Head Net Weight: 4.0kg - Operation Mode: Automated/Handheld - Supply Voltage: SLC-1500/2000 (Single phase three-wire system AC220±10%V); SLC-3000 (Three phase five-wire system AC380±10%V) - Utility Frequency: 50Hz - Working Temperature: 0℃~40℃ - Storage Temperature: -10℃~60℃ - Power Consumption @25℃: <6kW (SLC-1500); <10kW (SLC-2000); <14kW (SLC-3000) |

Other Details

1.Configuration

| Configuration Type | English Details |

|---|---|

| Standard Configuration | - Cleaning Host: 7-inch display, Type A cleaning head, 10m operating cable, red light indication, external control interface - Laser Protective Glasses: 1 pair (Compliant with EU EN207:2009/AC2011 & CE certification, protection band 190~400nm & 800~1100nm) - Lens Wiping Paper: 2 boxes - Replaceable Field Lenses: 1 set (Including 4 field lens protection lenses) - Warranty: 1 year |

| Selective Assembly | - Customized Communication - Fume Purifier - Wireless Remote Start-Stop - Integrated Cart |

2.Safety & Operation

- The equipment is a Class IV laser product with a central wavelength of 1080nm (invisible light). Direct or indirect contact with laser may cause irreversible eye damage and skin burns; operators must wear laser protective glasses throughout the operation.

- Emergency Stop Button: Located on the right side of the operation panel (red mushroom head), press immediately in case of abnormality, and rotate clockwise to reset.

- Operation Steps: Power on → Enter password "9527" to unlock → Adjust process parameters (power, frequency, etc.) → Select scanning pattern → Start laser cleaning (maintain 1-3mm focusing distance between cleaning head and workpiece for handheld operation).

- Precautions: Reserve 10cm ventilation distance around the equipment; fiber bend radius not less than 200mm; do not place flammable and explosive materials near the equipment; cover the laser output head with a protective cover when not in use.

Sample Display

|

|

Product appearance subject to actual delivery

EN

EN

AR

AR CS

CS NL

NL FR

FR DE

DE IT

IT JA

JA KO

KO PL

PL PT

PT RU

RU ES

ES UK

UK TH

TH TR

TR