SKYLC-SPM-100/200/300 Laser Cleaning Equipment - Non-contact & Damage-free

Product Description

SKYLC-SPM-100/200/300 is a high-performance industrial laser cleaning equipment developed for solving surface contamination problems of metal and partial non-metallic materials. Adopting high peak power pulsed laser, high-speed scanning system and self-developed high-precision control system, it effectively realizes rust removal, paint stripping, oil removal, oxide film cleaning, and pre-treatment for welding black ash cleaning, painting and texturing.

Compared with traditional cleaning methods, this non-contact laser cleaning machine has prominent advantages: it causes no damage to the substrate, produces no secondary pollution with recyclable cleaned substances, achieves micron-level precision control in thickness direction, and features no consumables, ultra-energy-saving and high cost-effectiveness. Equipped with universal wheels and external control system, it supports handheld or automated operation, and can be integrated with robotics and CNC systems. It is widely applied in aerospace, rail transportation, automotive manufacturing, marine vessels, mold processing, additive manufacturing and semiconductor fields.

Product Parameters

| Parameter Category | Specific Parameters |

|---|---|

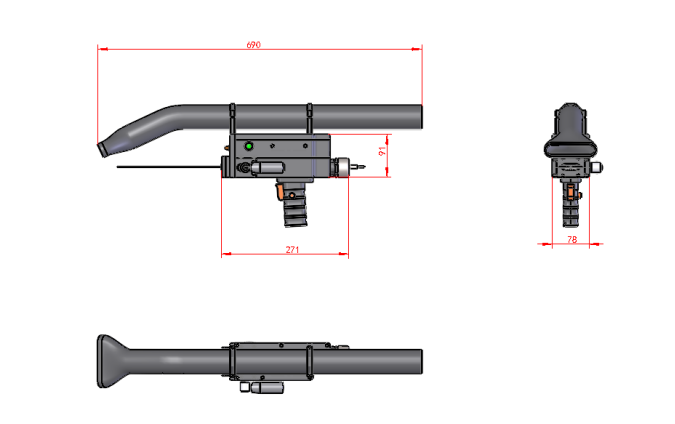

| Optical Property Parameters | - Cleaning head model: Type A - Laser average power: 100W/200W/300W - Power adjustable range: 10%~100% - Polarization direction: Arbitrary - Laser line width: 5mm~100mm adjustable - Fiber length: 5m - Minimum fiber bend radius: 150mm - Cooling mode: Water cooling + Air condition - Guided laser function: Available - Anti-high-reflection function: Available - Field lens model: F160/F210/F254(optimized by actual working conditions) |

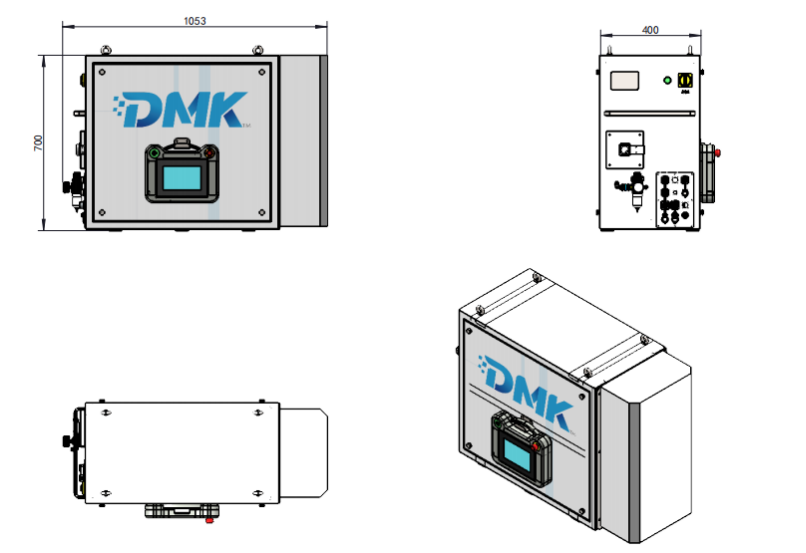

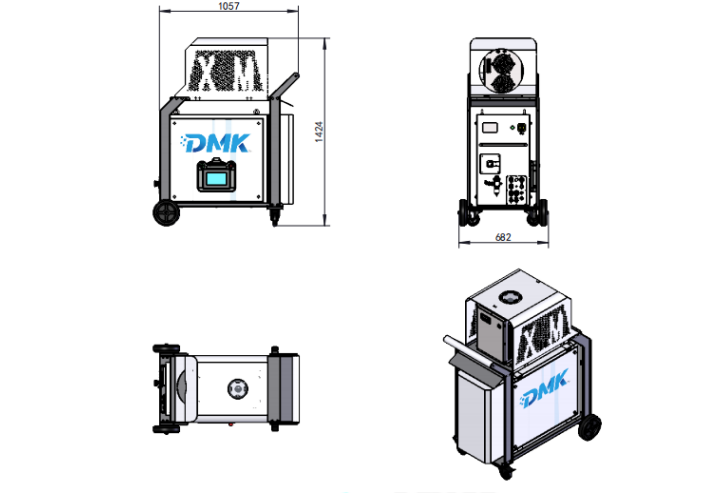

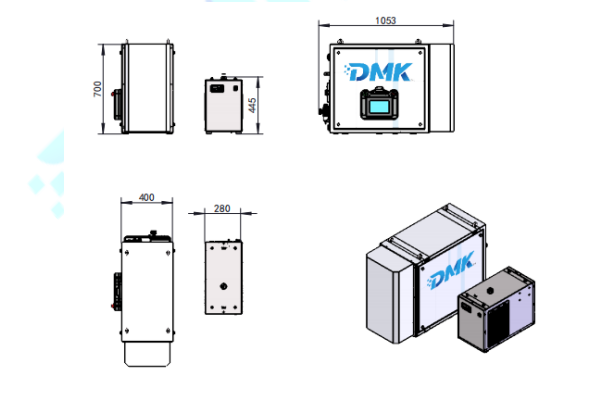

| General Property Parameters | - Chassis size: SPM-100: L1053mm×W400mm×H700mm SPM-200/300 (Integrated): L1075mm×W735mm×H1402mm SPM-200/300 (Split): Host L1030mm×W400mm×H700mm; Water cooler L560mm×W290mm×H445mm - Net weight: SPM-100: Host 80kg; Cleaning head 2.8kg SPM-200/300 (Integrated): 120kg; Cleaning head 2.8kg SPM-200/300 (Split): Host 85kg; Water cooler 20kg; Cleaning head 2.8kg - Operate mode: Automated / Handheld - Supply voltage: Single phase three-wire system AC 220±10% V - Utility frequency: 50Hz - Work temperature: 0℃~40℃ - Storage temperature: -10℃~60℃ - Power consumption: SPM-100<1000w; SPM-200/300<3200w |

Other Details

1.Configuration

| Configuration Type | Details |

|---|---|

| Standard Configuration | - IP54 level constant temperature cleaning host(: 7-inch display, 5m operating cable, red light indication, external control start/stop, alarm fault output - Water cooler: 1 set (100W equipment excluded) - Laser protective glasses: 1 pair(compliant with EU EN207:2009/AC2011&CE certification) - Lens wiping paper: 2 boxes - Replaceable field lenses: Including 4 field lens protection lenses - Warranty: 1 year |

| Selective Assembly | Customized Communication, Fume Purifier, Wireless Remote Start-Stop, Integrated cart |

2. Safety & Operation(安全与操作)

- The equipment is Class IV laser product with laser wavelength 1064nm, requiring operators to wear laser protective glasses throughout operation.

- Emergency stop button is located on the right of the operation panel; press to stop immediately in abnormal situations, and rotate clockwise to reset.

- Operation steps: Power on → Enter password "9527" to unlock → Adjust parameters (power, scanning width/frequency/speed, etc.) → Enable red light and laser → Start cleaning (maintain 1-3mm from focusing distance during handheld operation).

3. Maintenance & Troubleshooting

| Daily Maintenance | Common Troubleshooting |

|---|---|

| - Clean the cleaning head lens with special wipes after each use - Check chassis buttons, knob tightness and water tank temperature (≤40℃) before use - Clean equipment surface and ventilation filter weekly - Add antifreeze in winter (refer to proportioning chart for temperature adaptation) | - No power on: Check emergency stop switch reset, power connection and air switch - No red light: Confirm laser operation, power connection and red light enable status - No laser output: Verify "Start" button, DB25 line and optical path - Weak laser output: Clean the field lens of the handheld head |

4. Packing, Transportation & Storage

- Packing: Fix optical fiber (bend radius ≥150mm), wrap with foam and film, lock universal wheels.

- Transportation: Keep vertical, avoid vibration/collision/inversion, use closed cabins for long-distance transport.

- Storage: Avoid water, direct sunlight, strong electric/magnetic fields, corrosive gas; meet temperature (-10℃~60℃) and humidity requirements.

Sample Display

|

SKYLC-SPM-100 appearance (Product appearance subject to actual delivery) |

SKYLC-SPM-200/300 Integrated-type Appearance Diagram (Product appearance subject to actual delivery) |

|

SKYLC-SPM-200/300 Split-type Appearance Diagram (Product appearance subject to actual delivery) |

SKYLC-SPM-100/200/300 cleaning head |

EN

EN

AR

AR CS

CS NL

NL FR

FR DE

DE IT

IT JA

JA KO

KO PL

PL PT

PT RU

RU ES

ES UK

UK TH

TH TR

TR