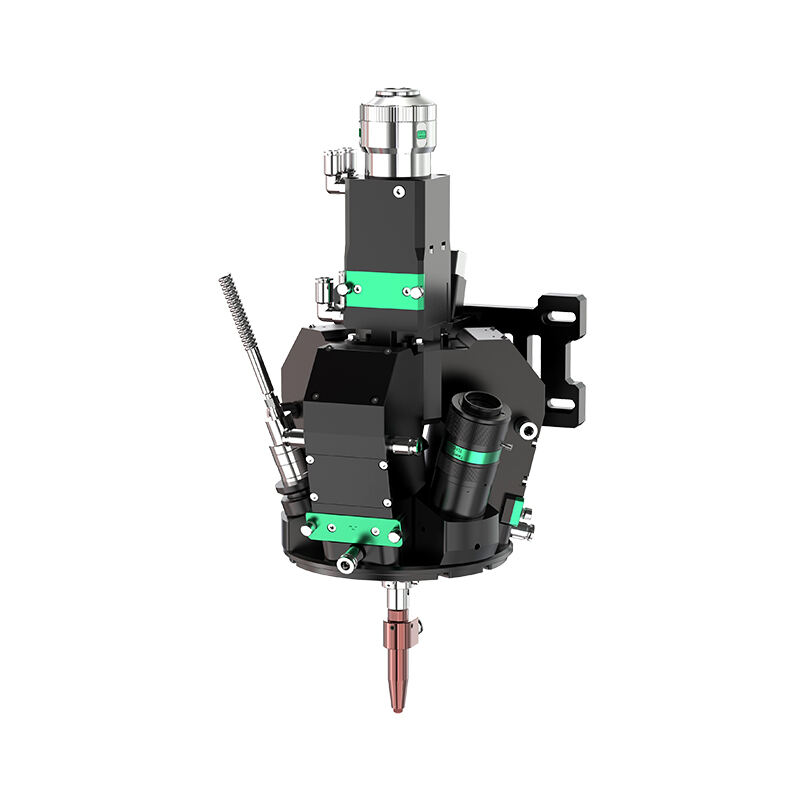

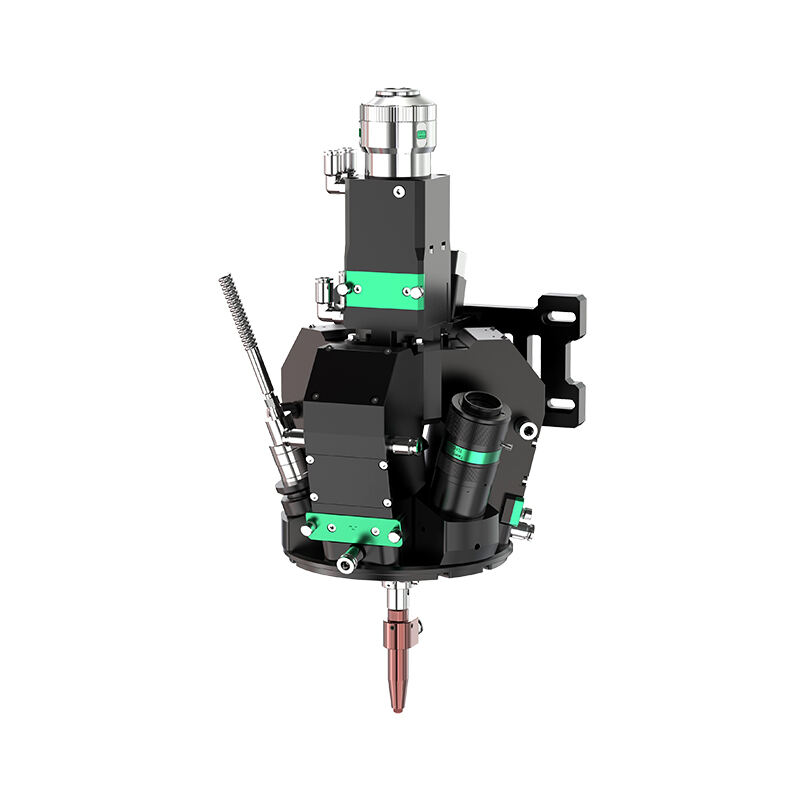

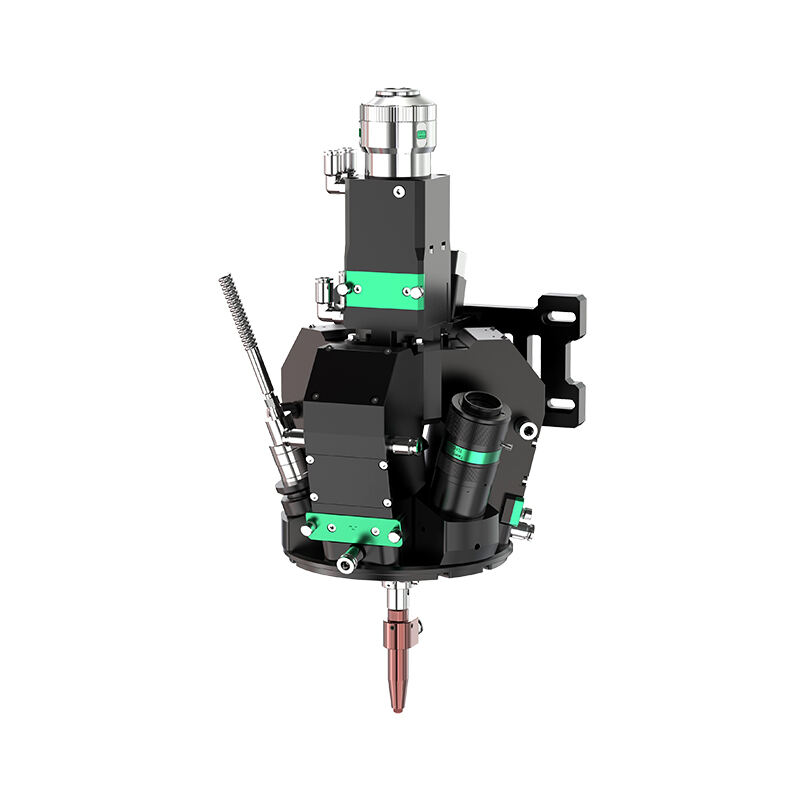

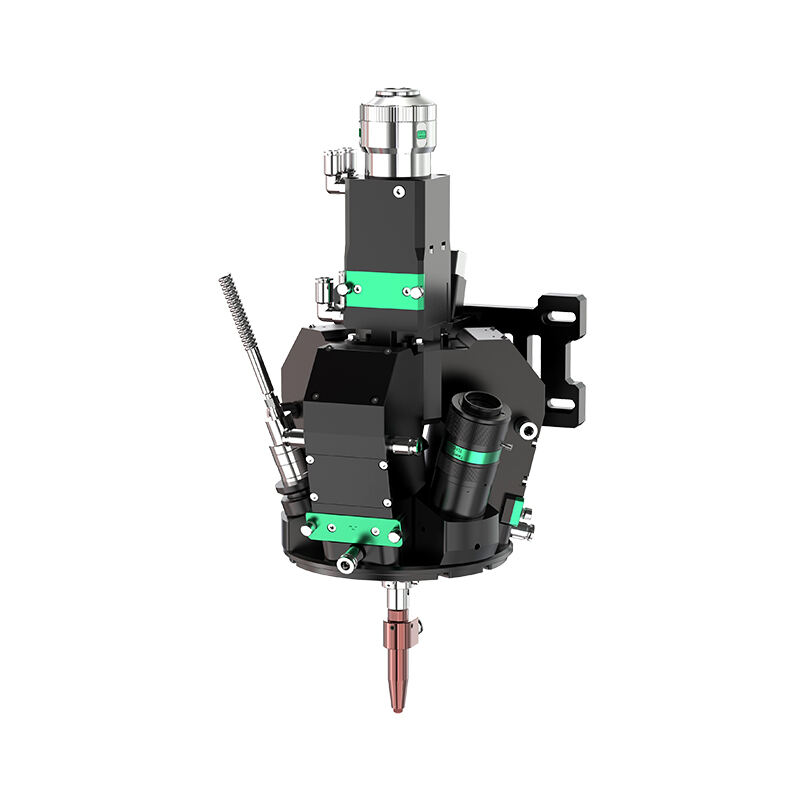

Raytools 6000W BP06K Coaxial Wire Feed Laser Processing Head

Description

The BP06K coaxial wire feed laser head transforms incident laser light into three beams with uniform energy distribution. These beams are reflected and focused to converge in a conical shape along the vertical direction, effectively enveloping the wire material to melt it uniformly. Compared to foreign products, the optical design of the BP06K is simpler and more cost-effective.

Advantages

High Cost-Effectiveness: The simple and reliable optical design results in lower operational costs. Its compact size and lightweight construction enhance usability.

Excellent Cladding Quality: Utilizing a three-beam wire wrapping scheme, the wire material or powder is output coaxially, ensuring uniformity and minimal directional bias, which reduces spatter during the melting process.

Optimized Structural Design: Features a unique structure with a 360-degree annular air knife protection system, preventing smoke and spatter from contaminating the lenses.

Efficient Cooling: Key lenses are equipped with direct water cooling, effectively reducing the impact of thermal lensing on performance.

Modular Design: Capable of integrating CCD cameras and closed-loop temperature control modules, allowing for effective monitoring of the processing quality and conditions.

Parameters

| Power level | Transmission Wavelength | Applicable Wire Diameter |

| 6000W | 900-1100mm | 0.8-1.6mm (0.8mm, 1.0mm, 1.2mm, 1.6mm diameters respectively) Adaptable wire diameter |

| Coaxial Protective Gas Flow | Air Knife Protective Gas Flow | Weight |

| 0-20L/min | 0-40L/min | ~8.0kg |

Applications

The BP06K coaxial wire feed laser processing head is ideal for various industrial applications, including:

- High-quality cladding of components using wire or powder materials.

- Precision repairs and enhancements of existing parts.

- Advanced manufacturing processes requiring controlled melting and deposition.

EN

EN

AR

AR CS

CS NL

NL FR

FR DE

DE IT

IT JA

JA KO

KO PL

PL PT

PT RU

RU ES

ES UK

UK TH

TH TR

TR