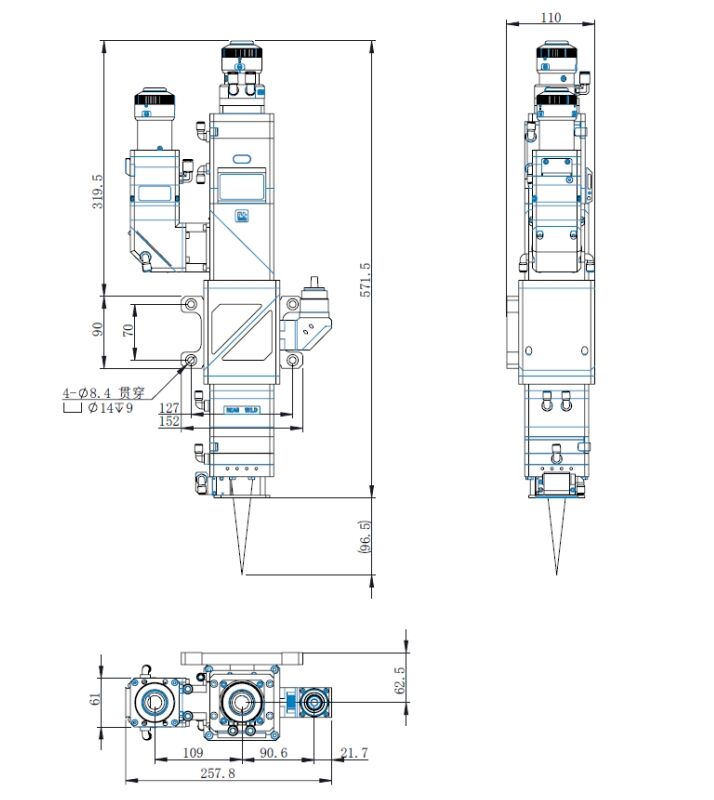

Raytool BW06H Dual-Band Hybrid Laser Welding Head

Description

The BW06H Dual-Band Hybrid Welding Head is an advanced optical system engineered for high-performance welding of reflective metals. Combining 4,000W fiber laser and 2,000W semiconductor laser energy (≤6,000W total), it overcomes traditional welding limitations by simultaneously delivering two complementary laser wavelengths. This synergy stabilizes the welding process on challenging materials like copper, aluminum, and brass while enabling real-time quality control via integrated HD CCD monitoring. Designed for industrial automation, it features rapid-maintenance components and robust thermal management for 24/7 operation.

Parameters

| Total Power Capacity | ≤ 6,000W |

| Power level | Optical fiber 4000W + semiconductor 2000W |

| Clear Aperture | Optical fiber 35mm, semiconductor 48mm |

| Laser wavelength | Fiber 1064nm, semiconductor 915-450nm |

| Weight | ~9.0kg |

Advantages

New Energy Vehicle (NEV) Battery Manufacturing

Application: Welding copper/aluminum busbars, cell connectors, and battery trays.

Benefit: Near-zero spatter prevents internal short circuits; ≤0.3 mm distortion on thin foils.

Consumer Electronics

Application: Hermetic sealing of stainless steel/Al alloy smartphone cases, laptop heat sinks.

Benefit: Aesthetic seam quality (Ra ≤ 1.6 μm) with 100% leak-tight integrity.

Home Appliance Compressors

Application: Joining copper refrigerant tubes to aluminum compressor bodies (e.g., refrigerators/AC units).

Benefit: Eliminates flux contamination; withstands 35+ bar pressure.

Power Electronics

Application: IGBT module copper baseplates, inverter housings.

Benefit: 40% faster welding vs. TIG; no post-weld cleaning required.

Industrial Machinery

Application: Thin-wall stainless steel/brass fluid system components (valves, pumps).

Benefit: Consistent penetration on 0.8–2 mm sheets; H2/He leak rate < 1×10⁻⁹ mbar·L/s.

Applications

Ideal for high-value manufacturing where weld integrity is critical:

Reflective Metal Welding

Electric Vehicles: Battery busbars, cell connectors, copper terminals.

Power Electronics: IGBT cooling plates, inverter housings.

Aerospace: Fuel system components, heat exchangers.

Precision Components

Jewelry (gold/silver) micro-welding

Medical device hermetic sealing

Sensor & microelectronics packaging

Automation Scenarios

High-speed robotic welding cells

Zero-defect production lines (e.g., battery gigafactories)

Lights-out manufacturing environments

EN

EN

AR

AR CS

CS NL

NL FR

FR DE

DE IT

IT JA

JA KO

KO PL

PL PT

PT RU

RU ES

ES UK

UK TH

TH TR

TR