Precision Laser Spot Welding Machine

Product Description

This precision welding machine features our pulse laser, which has several key advantages over traditional lasers:

- High Efficiency: Optimal energy use.

- Compact Design: Easy to integrate.

- No Maintenance Required: Hassle-free operation.

- Flexible Fiber Output: Versatile applications.

Our pulse laser combines optics, mechanics, electronics, and software for enhanced performance. It allows real-time monitoring and data collection through a user-friendly interface.

Designed with an air-cooling system, it offers low energy consumption and is convenient for integration, making it ideal for industrial laser welding and various applications.

Product Features

-

Real-Time Laser Power Feedback Control: Our system allows for real-time feedback and arbitrary waveform control, ensuring high-quality and stable processing for various workpieces.

-

16 Processing Standards: Equipped with 16 different processing specifications and waveform control functions to accommodate a wide range of materials.

-

Fast Standard Switching: Capable of instantaneous switching between standards, enabling high-speed and high-quality welding.

-

Homogenized Optical System: Designed for processing small weld point diameters.

-

Multi-Channel Output: Features the P4 series with up to 4 output branches (optional), allowing for versatile configurations.

-

Uniform Power Distribution: Each branch can achieve uniform output power, simplifying operation and maintenance.

-

Simplified Wiring and Operation: Easier and more straightforward than previous models, enhancing user experience.

-

User-Friendly LCD Interface: Input specifications directly on the LCD screen for simple and accurate operation.

-

Rich I/O Terminals: Equipped with numerous input/output terminals (signals) for easy integration with various automation equipment.

-

Energy Monitoring Function: Enables monitoring of laser output energy (J) and average energy (W), with upper and lower limit determination for quality management.

-

High-Precision QBH Fiber: Available with a maximum cable length of 10 meters to meet diverse needs.

-

External Communication Capability: (Optional) Allows centralized management of laser device specifications and monitoring data, compact design improves workshop environment.

-

Optional 10.1-Inch HD Screen: Combines welding process monitoring with laser system functionality.

-

Air-Cooled System: This product is designed as an air-cooled series, eliminating the need for external cooling water, and features an intelligent air-cooling system for energy efficiency.

Product Advantages

|

Ergonomic Design with Flexible Accessibility Featuring comfortable manual ports and barrier-free access, this design offers a spacious working area with a flat processing surface and a removable bottom plate for enhanced versatility. |

|

|

Integrated water-air-cooling

• Generously sized for full load operation at max. 35°C

• Very large DI filter for optimal conductance

• µC controlled cooling water flow

|

Compact and Ergonomic WorkstationDesigned for efficiency and comfort, this workstation features an ergonomic microscope and arm position, a flat top surface for convenient placement of workpieces and tools, a spacious working chamber, and a compact footprint that ensures a comfortable seating position. |

|

|

Easy Mobility with Durable Wheels |

|

MicroWeld:

• Allows finest high precision welds

• Weld spot diameters smaller than 50 microns

• Enhanced range of applications

|

SweetSpot

• Consistent welding quality from the first pulse

• Large depth of field

• Reliable welding process

• Patented laser resonator design

• No first-pulse effect

• Excellent beam quality

|

Technical Parameters

| Model |

50W

|

60W

|

100W

|

120W

|

| Central wavelength |

1080nm

|

|||

| Light efficiency | 65% | |||

| Output fiber core diameter | 20(50,100 customizable)um | |||

| Output mode | QBH | |||

| Cooling method | air cooling | |||

| Storage temperature | 0-60℃ | |||

| Humidity |

<70 %

|

|||

| Operating temperature range |

10~35 ℃

|

|||

| Dimensions (W x D x H) |

300X500X460 mm

|

|||

| Weight | 25kg | |||

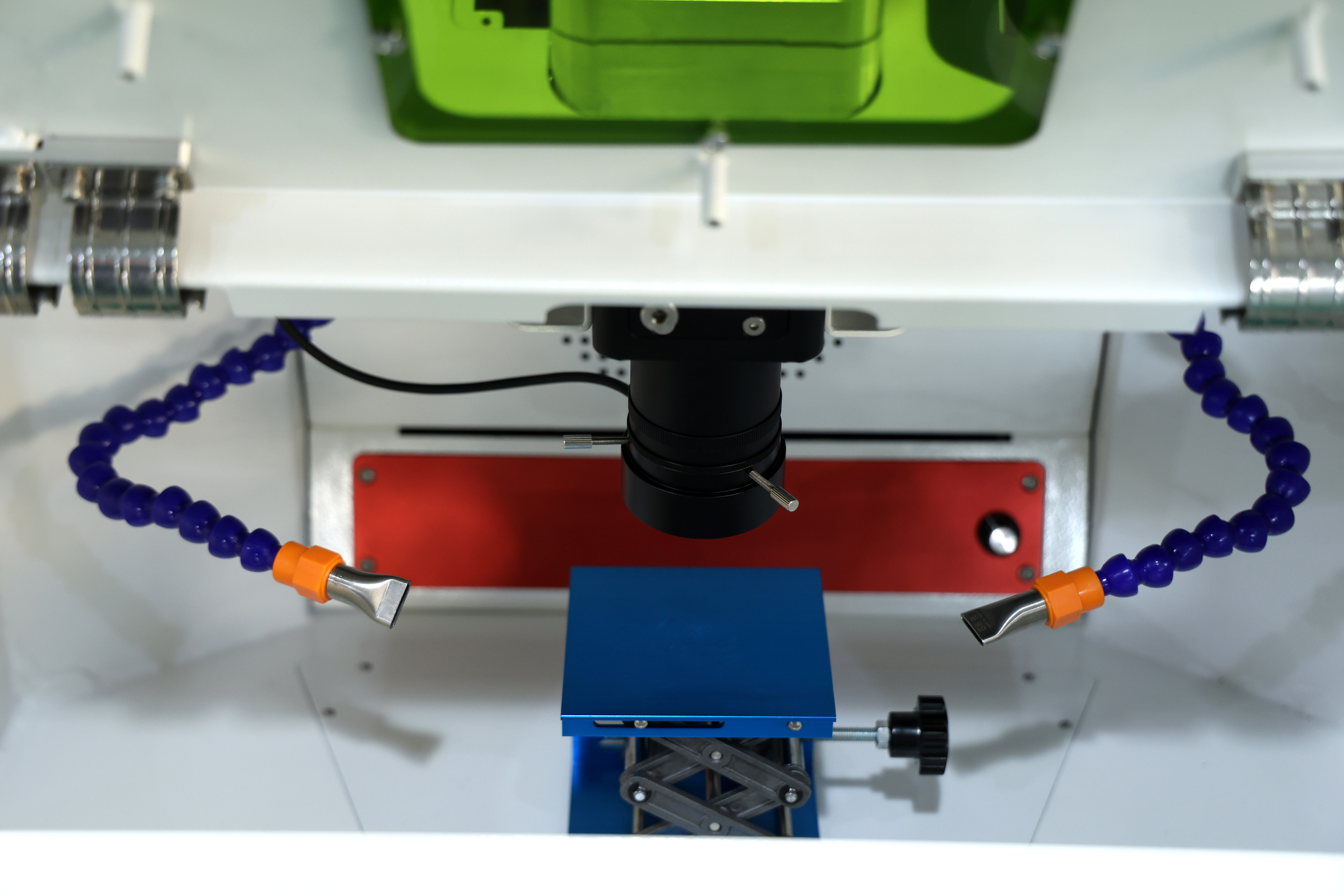

More Real Pictures

|

|

|

|

EN

EN

AR

AR CS

CS NL

NL FR

FR DE

DE IT

IT JA

JA KO

KO PL

PL PT

PT RU

RU ES

ES UK

UK TH

TH TR

TR