Portable New Model 20W-100W Fiber Optic Cabinet-type Laser Marking Machines Enclosed Design with Raycus Laser Source for Metal

An enclosed marking device equipped with core components including Raycus laser, Zhibotai double red-light galvanometer, etc. It supports 20W-100W power options, and is configured with functional modules such as rotating shaft and cross slide. It enables multi-process marking, suitable for precision processing and mass production scenarios.

Product Features

- High-End Core Components: Adopts 50W Raycus laser + Zhibotai double red-light galvanometer + JCZ control card and software, with output power stability < 5%. The core components deliver top-tier performance, ensuring marking precision and efficiency.

- Integrated Multi-Functional Modules: Standard-equipped with rotating shaft, cross slide and protective grating. It can realize circumferential marking of cylindrical workpieces and precise positioning of flat workpieces, balancing processing flexibility and operational safety.

- Wide Power & Range Options: Supports 20W/30W/50W/100W power switching and 100-300mm optional marking range, adapting to diverse needs from fine marking to deep engraving.

- High-Efficiency & Precision Marking: With engraving speed up to 10000mm/s, repeat precision of ±0.002mm and minimum line width of 0.1mm, it can complete high-quality marking of complex patterns and fine characters.

- Low-Threshold Compatible Operation: Compatible with Windows system, supporting full font library fonts and USB input. It can be quickly deployed with optional computer, and new users can get started after simple training.

Technical Parameters

| Laser Parameters | |

| Laser Power | 20W/30W/50W/100W (Optional) |

| Laser Wavelength | 1064±5nm |

| Output Power Stability | < 5% |

| Design Lifespan | ~100,000 Working Hours |

| Optical Characteristics | |

| Marking Range | 100~300mm (Range Optional) |

| Engraving Depth | ≤1mm (Depends on Power/Time) |

| Engraving Speed | ≤10000mm/s |

| Repeat Positioning Precision | ±0.002mm |

| Minimum Marking Line Width | 0.1mm |

| Minimum Character Height | 0.15mm |

| Usage Environment | |

| Cooling Method | Built-in Air Cooling |

| Power Supply | 500W/220V/50Hz |

| Applicable Temp & Humidity | 0~40°C; 30%≤RH≤85% |

| Oil Mist/Condensation Restriction | Not Allowed |

| Other Parameters | |

| Operating System | Windows Operating System |

| Supported File Formats | All Windows Fonts (USB Input) |

| Core Components | Raycus Laser, Zhibotai Galvanometer, JCZ Control Card |

| Functional Modules | Rotating Shaft, Cross Slide, Protective Grating |

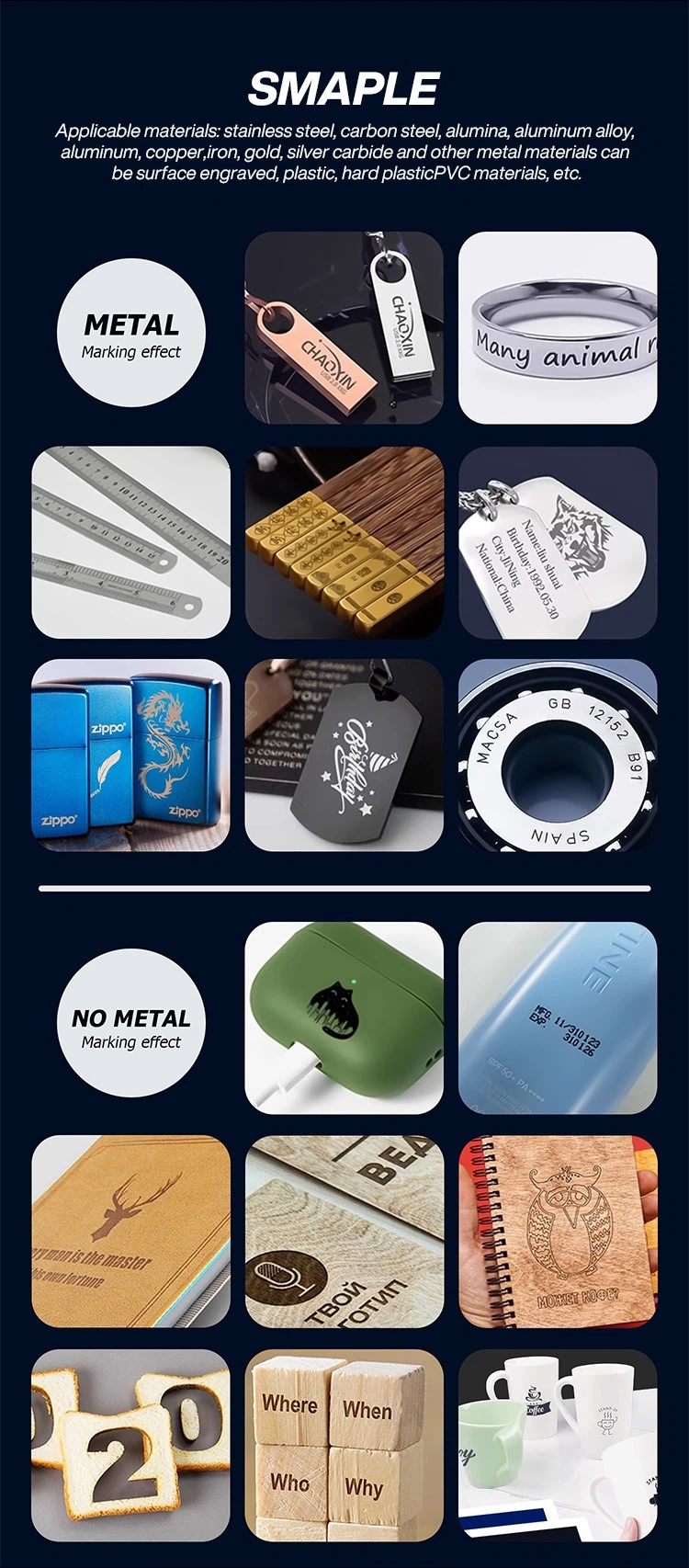

Application

- Precision Component Processing: Suitable for fine character/pattern marking of medical devices and optical components, meeting high-precision requirements.

- Cylindrical Workpiece Marking: The rotating shaft supports circumferential logo production of bottle caps, pipes and shaft parts.

- Mass Industrial Production: The cross slide + high-power configuration is used for batch marking of auto parts and electronic components.

- Customized Processing: The wide power and range options adapt to personalized logo and texture engraving of cultural and creative products and hardware tools.

FAQ

What are the advantages of the device's core components?

Answer: The Raycus laser ensures power stability, the Zhibotai galvanometer improves marking precision, and the JCZ control card simplifies operation. The combination balances performance and ease of use.

What are the functions of the rotating shaft and cross slide?

Answer: The rotating shaft enables circumferential marking of cylindrical workpieces, while the cross slide supports precise positioning of flat workpieces, expanding the device's processing scenarios.

Can the marking range and power be adjusted as needed?

Answer: It supports 100-300mm optional marking range and 20W-100W power coverage, which can be flexibly configured according to processing needs.

Is the device complicated to operate?

Answer: No. It is compatible with Windows system and supports USB input. After equipping with an optional computer, new users can operate it independently after simple training.

What is the function of the protective grating?

Answer: It is a safety protection device that can detect human proximity and pause marking, reducing safety risks during operation.

EN

EN

AR

AR CS

CS NL

NL FR

FR DE

DE IT

IT JA

JA KO

KO PL

PL PT

PT RU

RU ES

ES UK

UK TH

TH TR

TR