NewVision Automated Welding Seam Quality Inspection System

Description

Ensure every weld meets the highest standards with the Weld Seam Quality Inspection System.

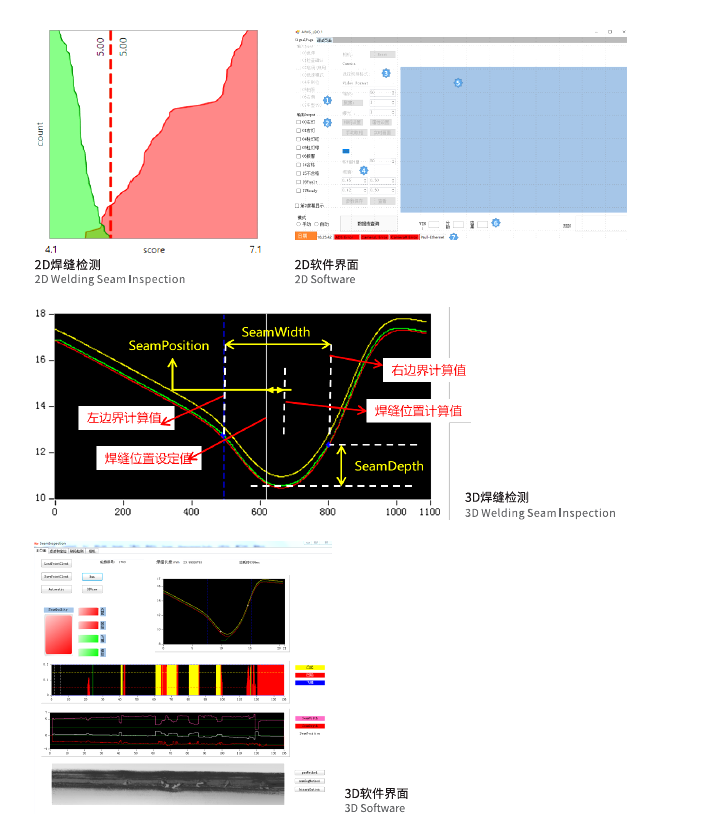

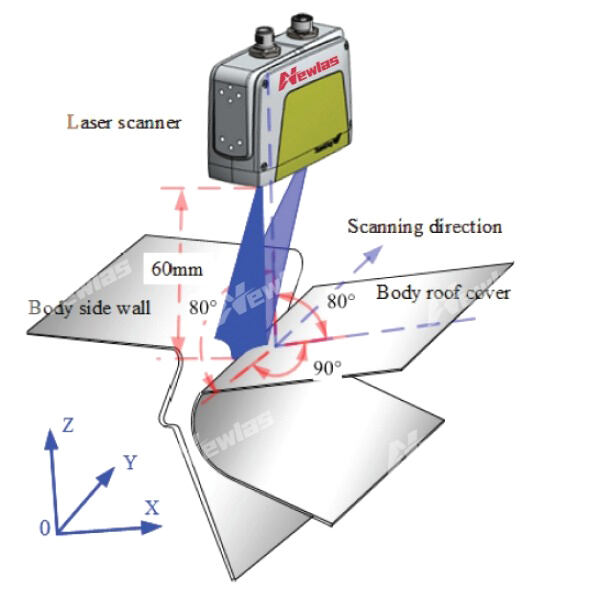

Powered by advanced 2D/3D vision technology and proprietary algorithms, it guides welding positions before the process and checks for defects immediately after — giving you complete confidence in weld integrity.

From automotive white body assembly to power battery production, it delivers speed, precision, and reliability you can trust.

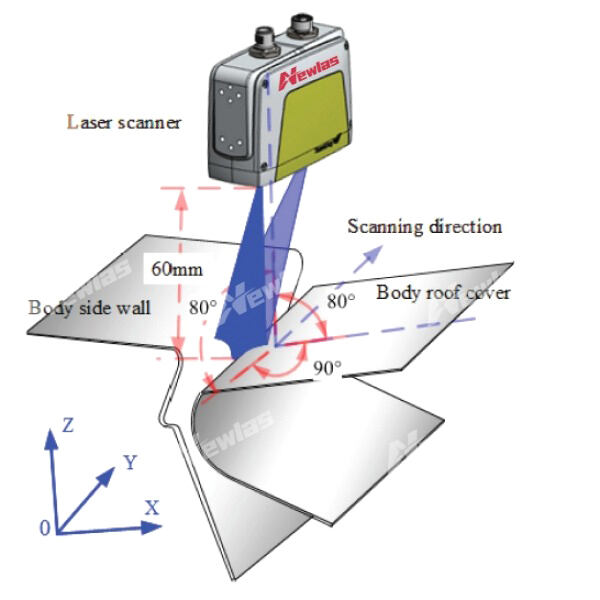

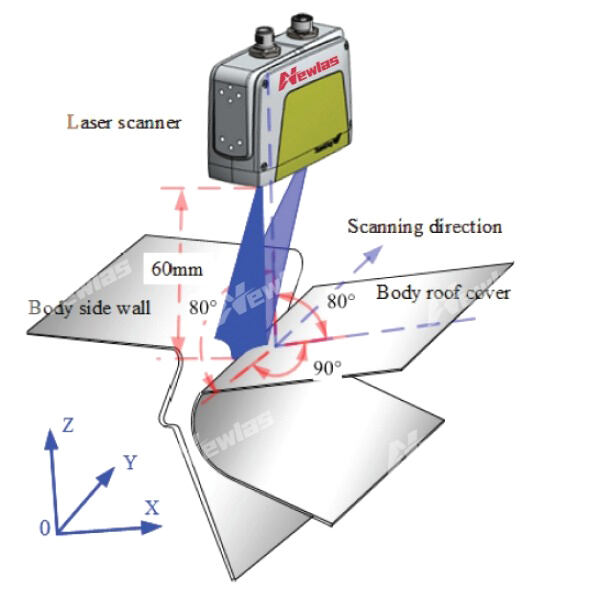

How it works

Advantages

Two-in-One Solution – Pre-weld positioning and post-weld inspection in a single system.

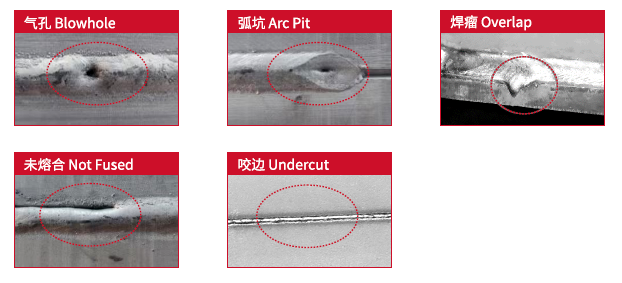

Full Defect Coverage – Detects porosity, arc craters, spatter, undercut, lack of fusion, and more.

Adaptable to Complex Welds – Works on thin plates, small gaps, and multiple seam types.

Visual Reporting – Online/offline analysis with clear 2D/3D visualizations.

Production-Ready Speed – Large field of view with high-speed scanning for maximum efficiency.

Defect Detection

Specifications

Vision Capability: 2D and 3D positioning

Detection Range: All common weld seam defects

Measurement Functions: Geometric weld measurement, position deviation detection

Data Analysis: Online/offline with visualization

Speed: High-speed detection for industrial production lines

Features

Proprietary self-developed algorithm for superior stability

Accurate positioning for multiple weld seam types

Large-field, high-speed detection for demanding industries

Easy integration with production monitoring systems

Suitable for both high-volume and precision manufacturing

Applications

Automotive white body welding – Hoods, doors, rear covers, side panels

Power battery welding – Casing seals, poles, busbars

EN

EN

AR

AR CS

CS NL

NL FR

FR DE

DE IT

IT JA

JA KO

KO PL

PL PT

PT RU

RU ES

ES UK

UK TH

TH TR

TR