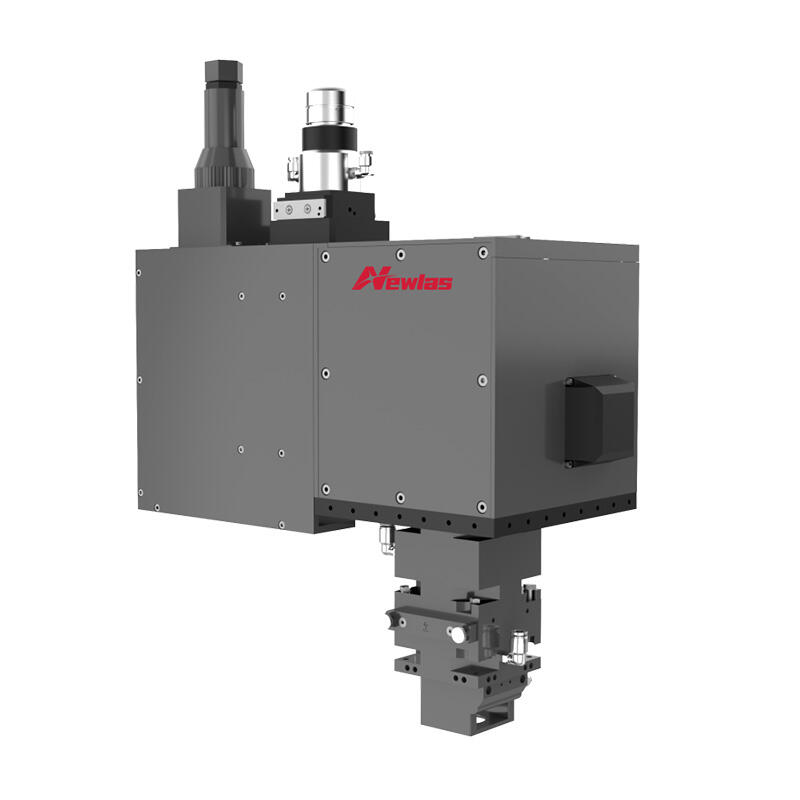

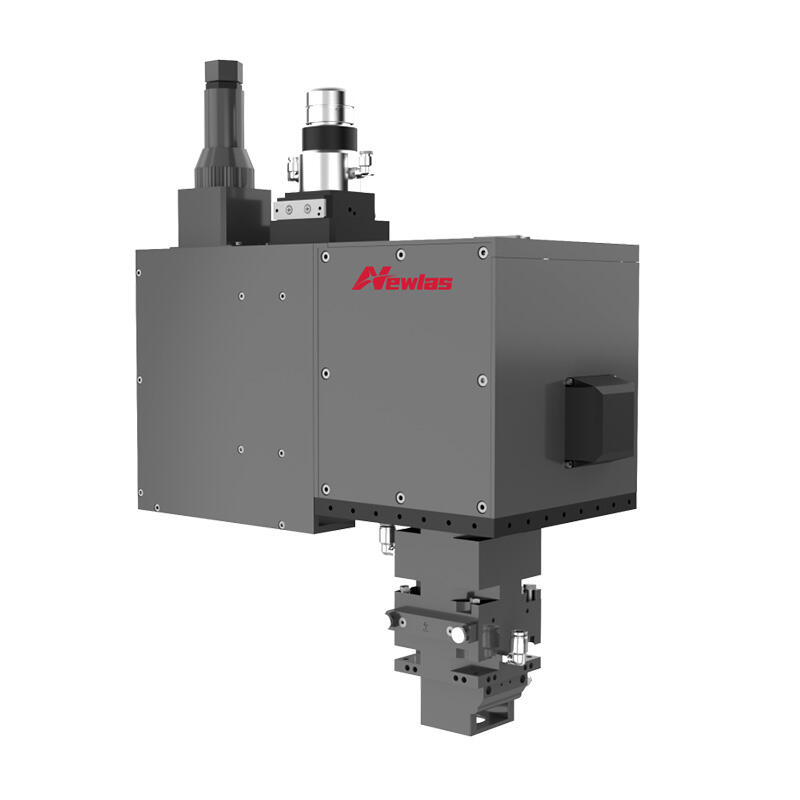

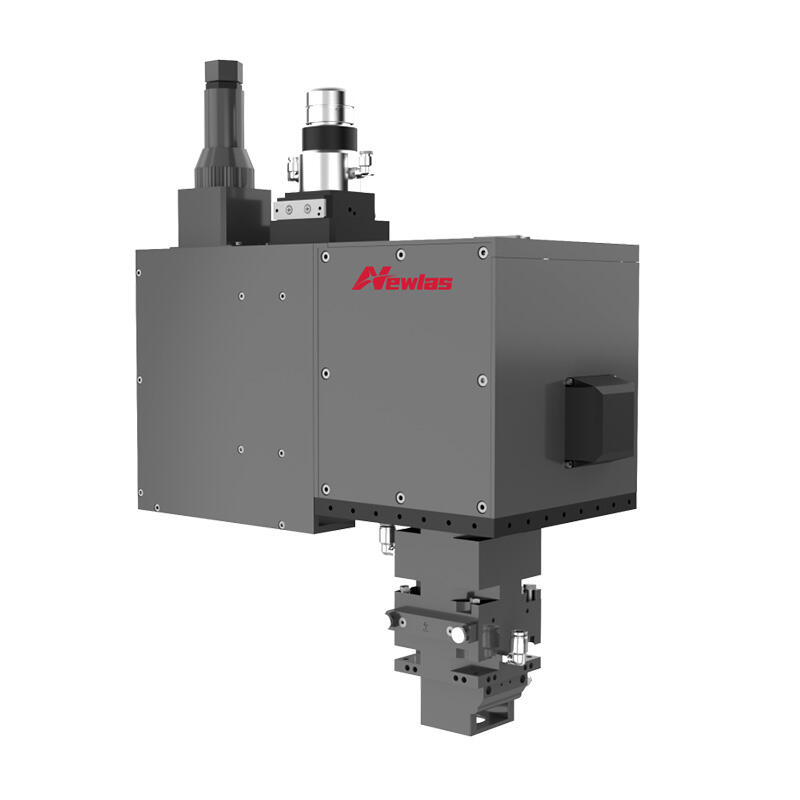

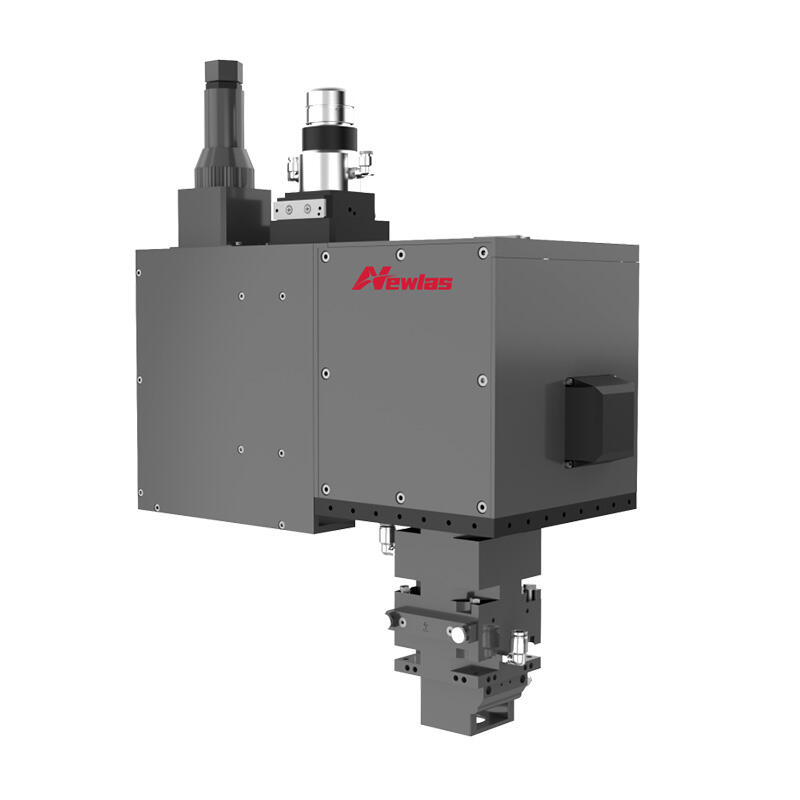

NewOCT Swing Welding Penetration Detection System

Description

The NewOCT Swing Welding Penetration Detection System is a dynamic welding solution that integrates high-precision laser low-coherence measurement for real-time, online penetration depth monitoring of various metals, including copper, aluminum, and steel.

By combining welding and penetration detection into one system, it ensures superior weld quality, process consistency, and streamlined production control.

Specifications

Penetration Depth Detection Resolution: < 0.02 mm

Penetration Depth Measurement Range: ≤ 12 mm

Detection Accuracy: ≤ 10%

Compatible Laser Types: Single-mode, multi-mode, and ring-spot lasers

Laser Power Handling: Up to 8 kW continuous operation

Supported Communication Protocols: Modbus TCP, Profinet (PN), EtherNet/IP (EIP)

Optional Modules: Protective lens contamination detection

Software: OCT detection software for pole and casing welding, customizable to production line needs

Features

Real-Time Penetration Depth Monitoring – Integrated OCT Metrix module ensures continuous quality control during welding.

Protective Lens Contamination Alert – Optional detection module prevents power loss and welding defects caused by lens pollution.

High Stability – Premium optical materials and coatings with minimal thermal effect, supporting long-duration, high-power welding.

Wide Compatibility – Works with mainstream domestic and international laser brands.

Flexible Communication – Supports multiple industrial communication protocols for MES integration.

Precision Control – Dedicated controller for synchronized welding and detection operations.

Applications

Automotive industry – Battery tabs, casing welding, structural components

Electronics manufacturing – Precision metal joining with strict quality control

Aerospace components – High-strength, defect-free welds

Industrial manufacturing – Copper, aluminum, and steel welding with penetration verification

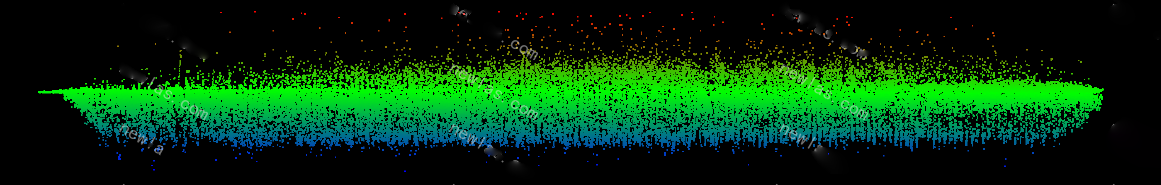

3D Depth of Melt Point Cloud Applications

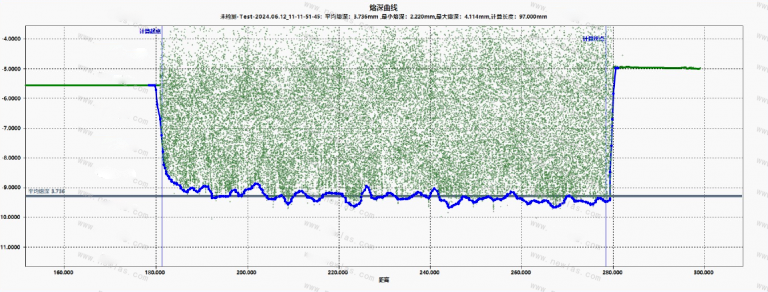

Depth of Melt Fitting Curve

EN

EN

AR

AR CS

CS NL

NL FR

FR DE

DE IT

IT JA

JA KO

KO PL

PL PT

PT RU

RU ES

ES UK

UK TH

TH TR

TR