NewOCT Flying Welding Penetration Depth Detection System

Product Overview

The NewOCT Flying Welding Penetration Depth Detection System integrates high-precision low-coherence laser measurement technology with laser welding, enabling real-time, online monitoring of weld penetration depth for copper, aluminum, steel, and other metals.

This all-in-one solution ensures 100% non-destructive inspection, making it ideal for high-demand industries such as busbar production and automotive floor panel spiral spot welding.

Key Features

Ultra-High Resolution – Penetration depth measurement resolution of <0.02 mm.

Deep Measurement Capability – Detects weld penetration depths up to 12 mm with accuracy ≤10% of penetration depth.

Full Coverage Inspection – Achieve 100% non-destructive inspection for every product.

Wide Laser Compatibility – Supports single-mode, multi-mode, and ring-spot fiber lasers.

Flexible Integration – Compatible with galvo welding heads, wobble welding heads, and fixed-focus welding heads.

Multi-Platform Use – Suitable for robotic welding systems, 3-axis systems, and more.

、

、

Advantages

Control Technology

Proprietary controller design with customizable functions.

Synchronizes welding and detection in real time.

Advanced low-level control for precise beam manipulation and high-accuracy measurement.

Software Technology

Customizable for specific production scenarios.

Proprietary welding and OCT detection software for rapid adaptation to production line needs.

Optical Technology

Custom-designed optical components optimized for OCT detection.

Optional lens contamination detection module for added safety and reliability.

Hardware Technology

Dedicated flying welding head with optimized optical path, lenses, and motors.

Real-time penetration depth detection during welding.

Standardized interfaces for easy integration; built with strict quality control for stability and reliability.

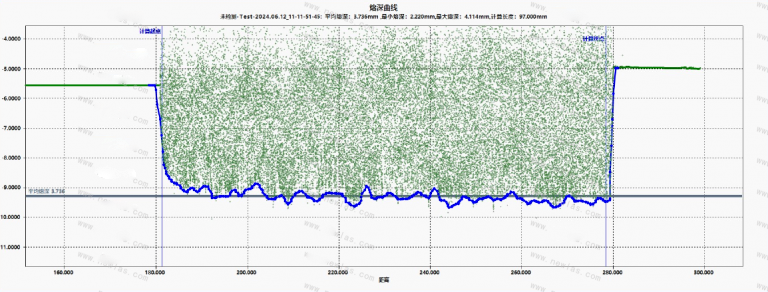

Depth of Melt Fitting Curve

Main Parameters

| Penetration Depth Resolution | <0.02 mm |

| Measurement Range | ≤12 mm |

| Measurement Accuracy | ≤10% of penetration depth |

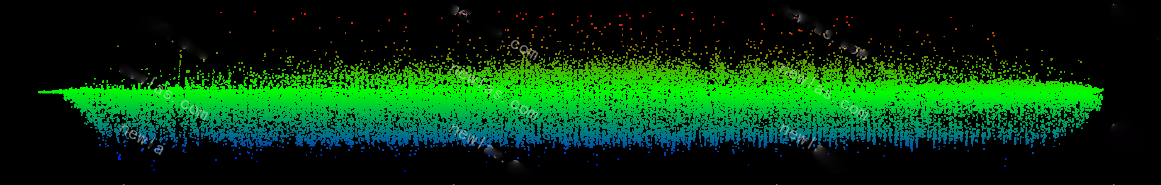

3D Depth of Melt Point Cloud Applications

Applications

Busbar Flying Welding

Automotive Floor Panel Spiral Spot Welding

EN

EN

AR

AR CS

CS NL

NL FR

FR DE

DE IT

IT JA

JA KO

KO PL

PL PT

PT RU

RU ES

ES UK

UK TH

TH TR

TR