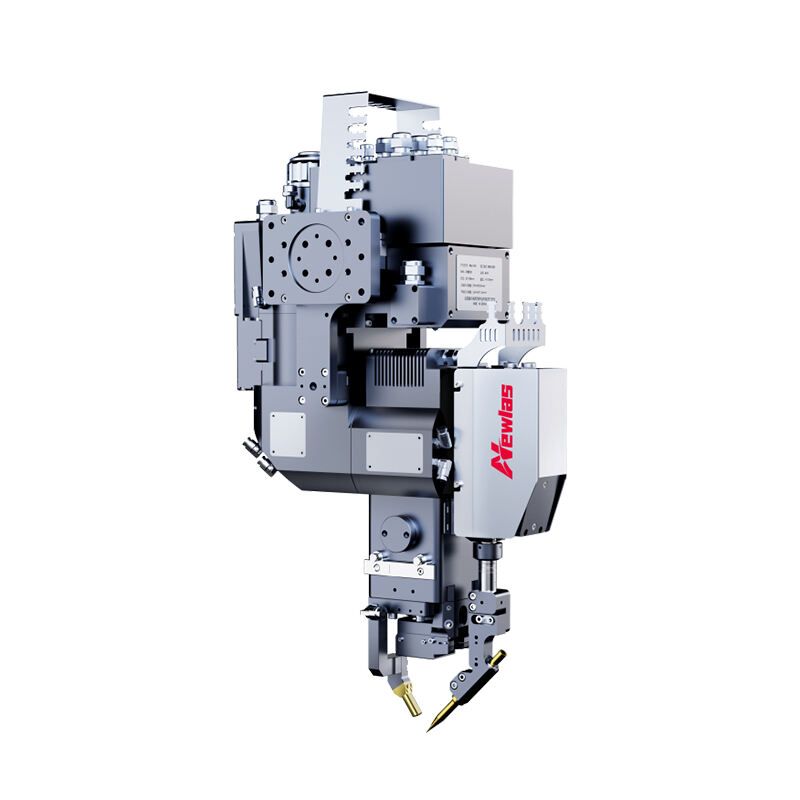

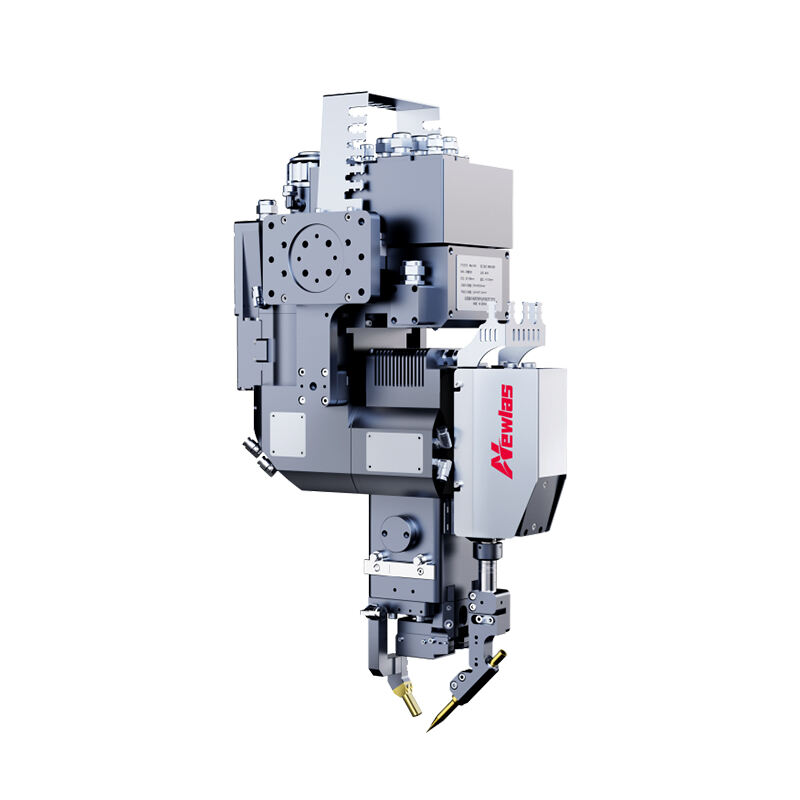

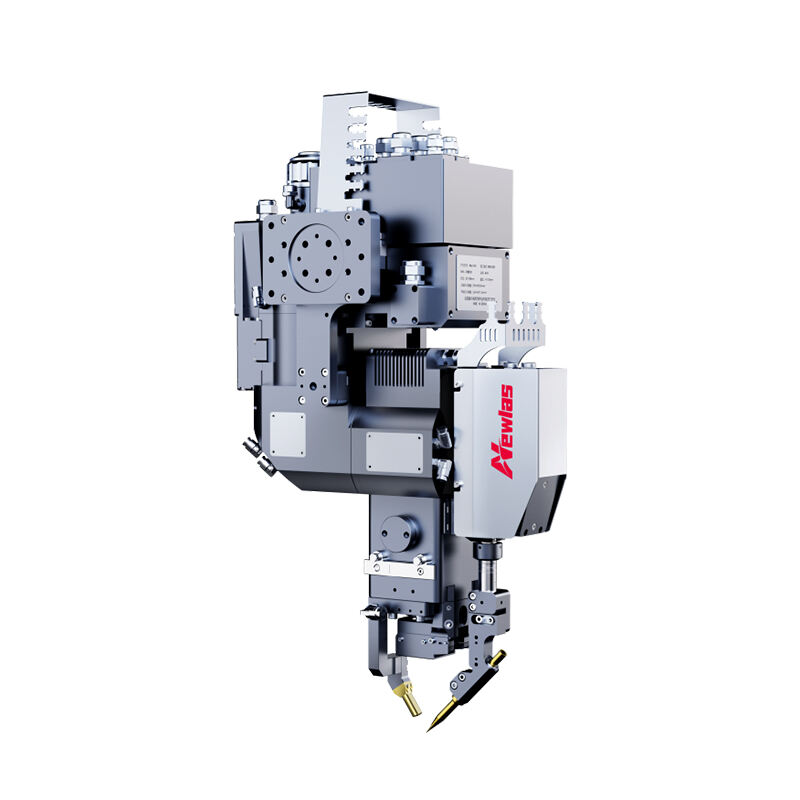

NewFO3 Smart Laser Wire Feeding Welding Head

Product Description

The NewFO3 laser wire feeding brazing & welding head takes welding precision and efficiency to the next level. Designed for electric vehicle production lines, it delivers stable, high-quality welds on critical components like car bodies, battery packs, and structural parts.

With automatic seam tracking and spot size control, every weld is consistent—no matter the part tolerance.

Why NewFO3 is the Smart Choice

Perfect Seam Tracking – Tactile wire sensing keeps the weld seam perfectly aligned, automatically correcting for part shifts.

Always Optimal Focus – Maintains the ideal laser spot size as the weld seam height changes, ensuring uniform penetration and finish.

Plug & Play Integration – Works seamlessly with your existing wire feeders, laser sources, and vision systems.

Built to Adapt – Modular design fits any laser source and expands easily with your production needs.

Operator-Friendly – Quick setup, compatible with international systems, and proven stability in demanding production lines.

Technical Specs

| Model | NewFO3 |

| Interface Type | QBH / QD |

| Wavelength Range | 1030–1090 nm |

| Max Power | 6 kW |

| Oscillation Range | ±90° |

| Focus Travel | 0–30 mm |

| Telescopic Arm Adjustment | ±5 mm |

| Cooling Method | Water-cooled |

| Power Supply | 24V / 10A |

| Protection Level | IP64 |

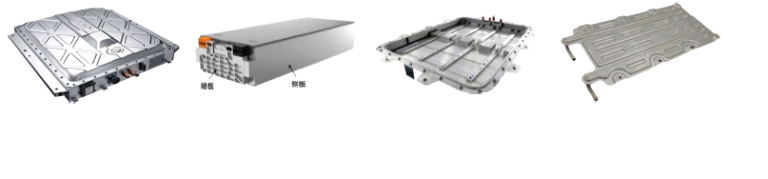

Where It Excels

Automotive Body Welding – Roof panels, tailgates, hoods, beams.

Battery Manufacturing – Packs, side plates, trays, cooling plates.

Component Assembly – Precision welding of metal parts.

EN

EN

AR

AR CS

CS NL

NL FR

FR DE

DE IT

IT JA

JA KO

KO PL

PL PT

PT RU

RU ES

ES UK

UK TH

TH TR

TR