Mold Repair YAG Laser Welding Equipment Manufacturer

Product Description

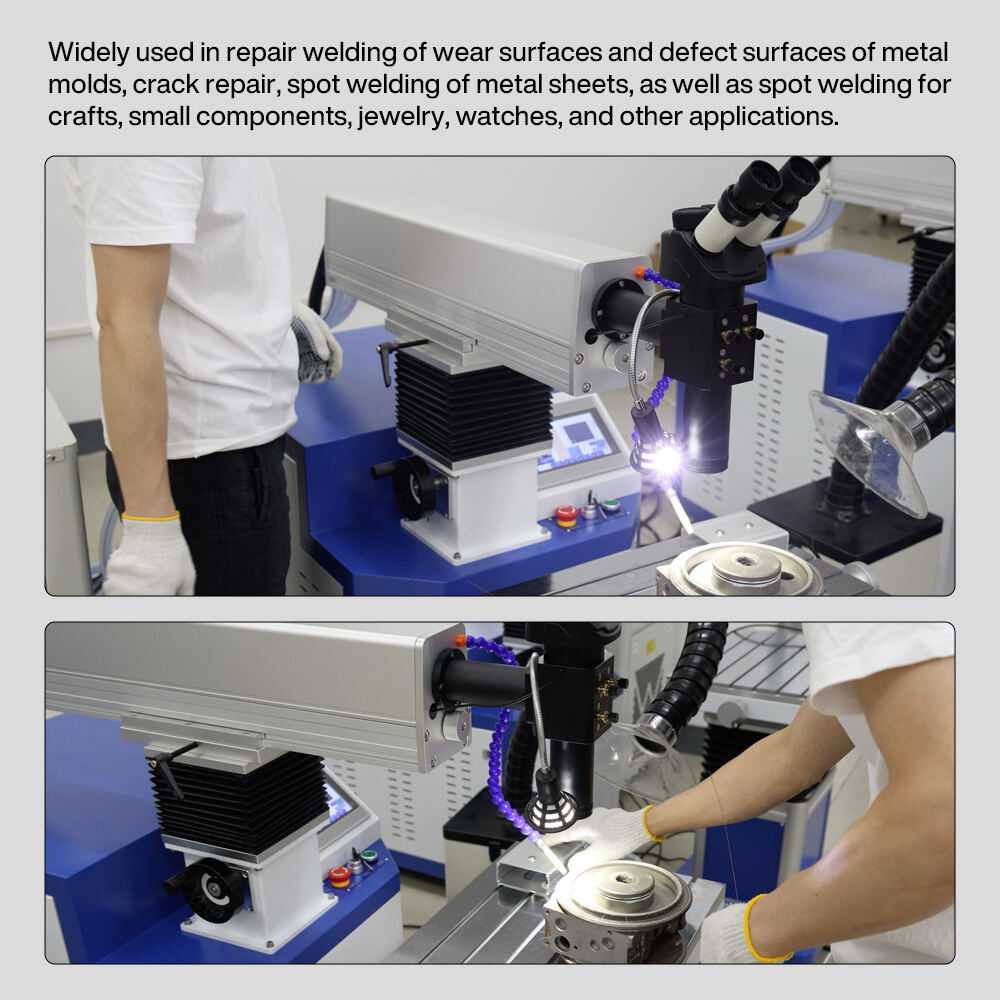

Our Mold Repair YAG Laser Welding Machine is purpose-built for precision mold repair, leveraging high-energy YAG laser pulses to melt and deposit material exactly where needed. Using concentrated heat, the machine fills cracks, pores, and chipping defects with minimal thermal distortion—eliminating drawbacks of traditional argon arc welding and reducing rework. Ideal for repairing plastic injection, die-casting, stamping, and tooling molds across industries like electronics, auto, and medical.

Key Advantages

Minimal Heat-Affected Zone: Reduces thermal stress and deformation on the mold

Excellent Bond Strength: Ensures high-quality welds that match or exceed the base material’s hardness

Versatile Metal Compatibility: Works with tool steels, stainless steel, copper, aluminum, titanium, and more

Flexible Configuration: Adaptable laser head design allows repairs on complex geometries

Durable Components: Long service life of laser cavity (8–10 years) and xenon lamps (8 million pulses)

User-Friendly Control: Digital interface with adjustable welding parameters and memory presets

Safe and Stable Operation: Built-in safety systems to protect operators and maintain consistent output

System Structure

YAG Laser Generator

Laser wavelength: 1064 nm

Available power options: 200W / 300W / 400W / 600W

High pulse energy and frequency with stable beam quality

Dual-pulse and single-pulse options

Beam Path & Focus Module

Rotating laser head for 360° operation

Spot size adjustable between 0.2 mm and 3.0 mm

Precision focusing for deep, smooth weld seams

Motion Platform

3-axis manual or motorized movement

Load capacity up to 200 kg

Optional rotary table for circular mold sections

Cooling System

High-efficiency water-cooling unit (1P–5P)

Ensures stable laser performance under continuous operation

Safety & Visual Systems

Protective gas system (argon)

Safety shielding, laser shutter, and light-blocking measures

Optional microscope or CCD camera for precise observation

Technical Specifications

| Specification | Value |

|---|---|

| Laser Power | 200W / 300W / 400W / 600W |

| Wavelength | 1064 nm |

| Pulse Energy | 60–110 J |

| Pulse Frequency | Up to 100 Hz |

| Spot Diameter | 0.2–3.0 mm (adjustable) |

| Cooling System | Water cooling (1P–5P) |

| Worktable Load | ≤200 kg |

| Movement Axes | Manual or motorized XYZ |

| Observation System | Microscope or CCD (optional) |

| Gas Protection | Argon |

Applications

Repair of plastic injection molds, die-casting molds, stamping molds, and rubber molds

Filling of cracks, corners, worn edges, holes, and damaged surfaces

Suitable for industries such as automotive, electronics, medical, toy manufacturing, and toolmaking

Supports product R&D with precision part modifications and enhancements

EN

EN

AR

AR CS

CS NL

NL FR

FR DE

DE IT

IT JA

JA KO

KO PL

PL PT

PT RU

RU ES

ES UK

UK TH

TH TR

TR