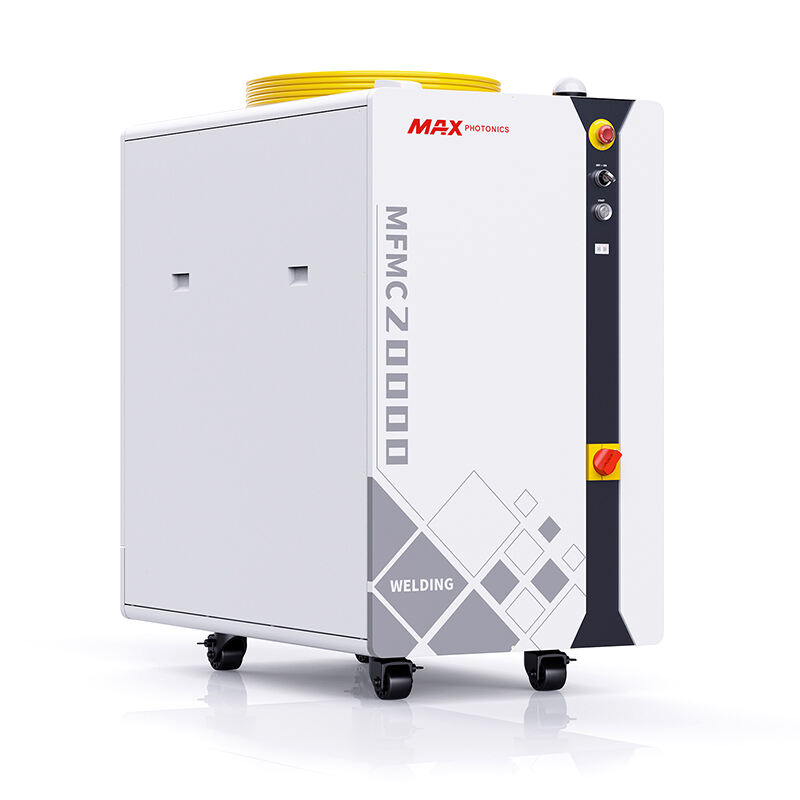

Max 20000-30000 Fiber Laser Welding Source

Product Description

The Max 20000-30000 Fiber Laser Welding Source is a high-performance fiber laser designed for welding heavy-duty materials, especially for industries like steel construction, power generation, shipbuilding, railway, and heavy machinery. Offering a fast response time (μs-level) and exceptional stability, this machine ensures high precision and high-quality welds for thick plates and other challenging welding tasks. It integrates advanced intelligent functions, including waveform editing, health diagnostics, and power feedback, providing unmatched versatility and reliability for demanding industrial applications.

Features

High-Speed Response (μs-Level)

With a microsecond-level response, this laser welding machine is perfect for high-precision welding tasks that require speed and accuracy.Exceptional Stability

Designed with high safety standards (PLD/PLE) and superior system stability, ensuring consistent welding performance and reliability in long-term operations.Waveform Editing Function

The laser includes a waveform editing card, enabling precise control of the laser output waveform to accommodate the unique needs of irregular workpieces.High System Compatibility

Compatible with various bus communication protocols (I/O communication, Ethernet, and more), allowing for easy integration into different industrial systems.Customizable Fiber Optic Diameter

Users can select different fiber core diameters (150μm, 200μm, 300μm) depending on their specific welding requirements, allowing for tailored applications.Superior Electrical-Optical Efficiency

With an electrical-optical conversion efficiency of ≥40%, this machine reduces energy consumption while maintaining top performance.

Specifications

| Parameter | MFMC-20000 (W) | MFMC-30000 (W) |

|---|---|---|

| Output Power (W) | 20000 | 30000 |

| Operating Mode | Continuous/Pulsed | Continuous/Pulsed |

| Polarization | Random | Random |

| Power Adjustment Range (%) | 5~100 | 5~100 |

| Center Wavelength (nm) | 1080±5 | 1080±5 |

| Spectral Bandwidth (3dB) (nm) | 5~8 | 5~8 |

| Short-Term Power Stability (%) | ±1 | ±1 |

| Long-Term Power Stability (%) | ±1.5 | ±1.5 |

| Beam Quality BPP | 5-6.5 (150μm) | 5-6.5 (150μm) |

| Laser On Time (μs) | <50 | <50 |

| Laser Off Time (μs) | <50 | <50 |

| Modulation Frequency (KHz) | 50 | 50 |

| Indicating Red Light Power (μW) | 200 | 200 |

| Output Cable Type | LOE | LOE |

| Fiber Cable Length (m) | 25 (Customizable) | 25 (Customizable) |

| Fiber Core Diameter (μm) | 150 (200/300 Optional) | 150 (200/300 Optional) |

| Fiber Cable Bend Radius (mm) | 200 | 200 |

| Working Voltage (VAC) | 400 (±40) | 400 (±40) |

| Rated Power Consumption (KW) | 53 | 80 |

| Operating Environment Temperature (°C) | 25 (10~40) | 25 (10~40) |

| Storage Temperature (°C) | -10~60 | -10~60 |

| Operating Environment Humidity (%) | 10~85 | 10~85 |

| Cooling Method | Water Cooling | Water Cooling |

| Machine Dimensions (W×D×H) (mm) | 700×1200×1140 | 700×1200×1140 |

| Machine Weight (kg) | 478±10 | 590±10 |

Applications

Steel Construction

Ideal for welding heavy-duty steel plates and components used in structural construction projects.Power Generation

Perfect for welding high-strength materials in the power generation sector, ensuring durable and high-quality results.Shipbuilding

Specially designed for welding thick plates and complex structures in shipbuilding, providing precision and durability in harsh marine environments.

EN

EN

AR

AR CS

CS NL

NL FR

FR DE

DE IT

IT JA

JA KO

KO PL

PL PT

PT RU

RU ES

ES UK

UK TH

TH TR

TR