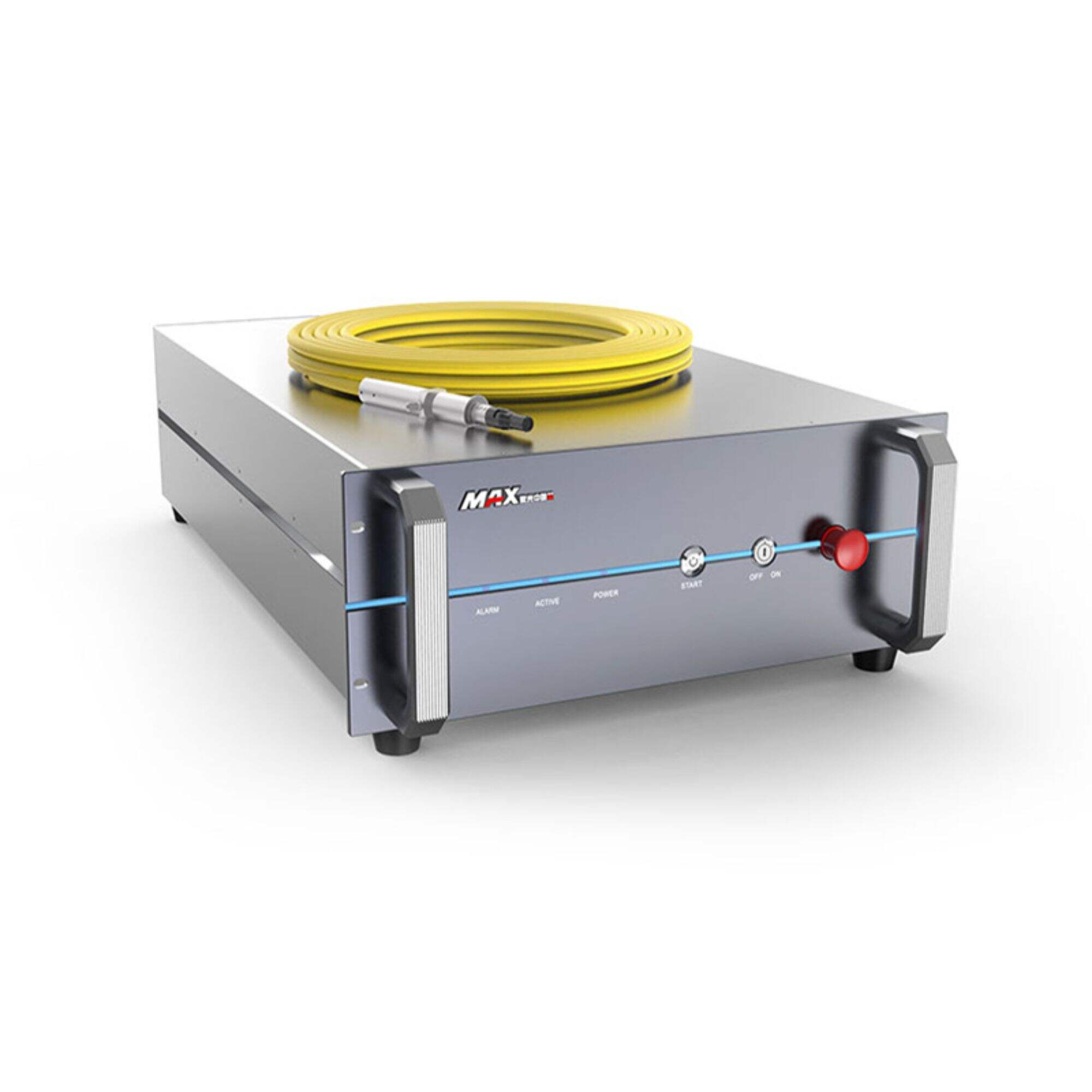

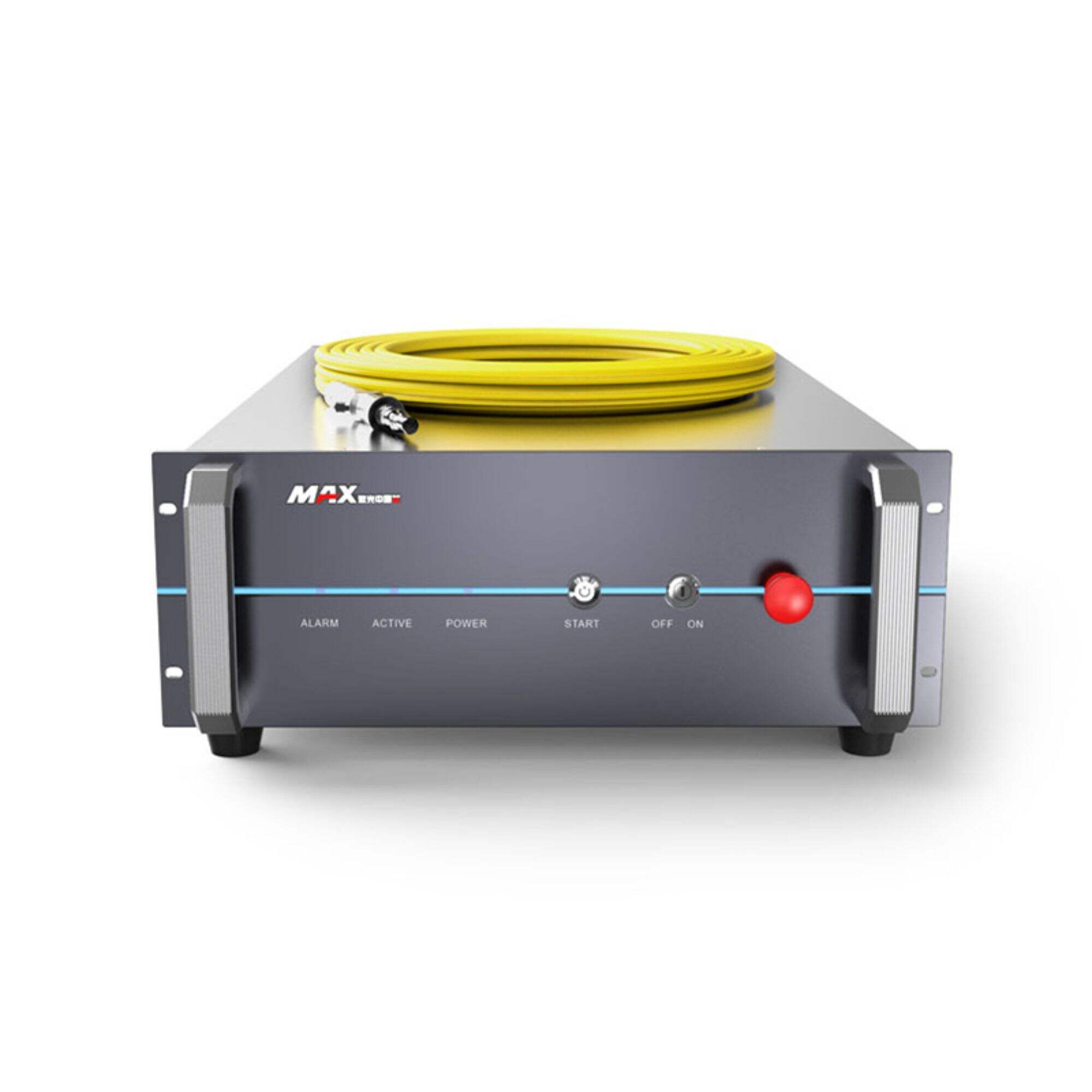

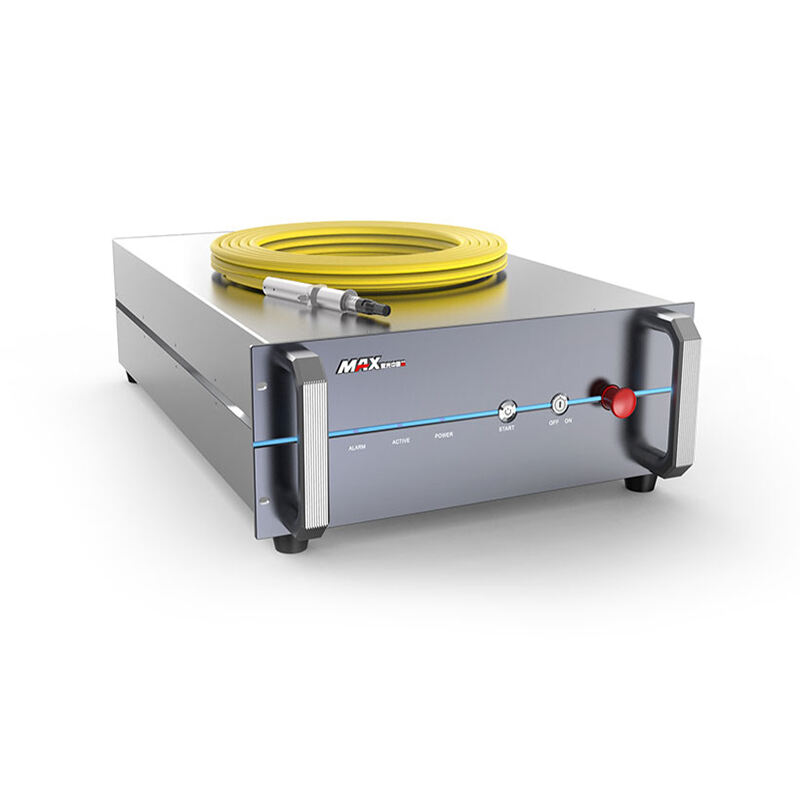

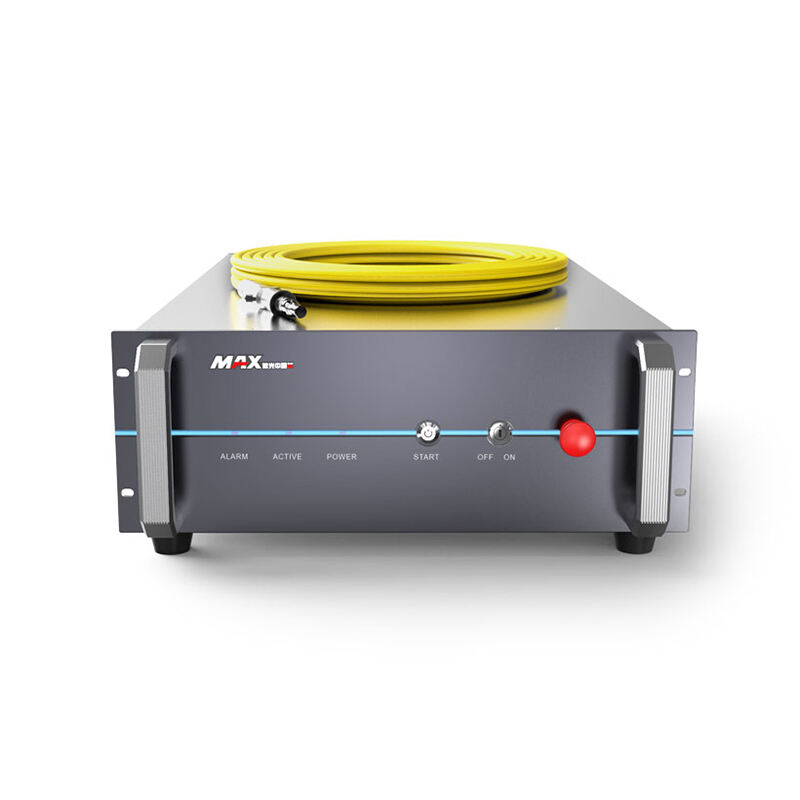

MAX 1500W Single-Mode Continuous Fiber Laser Generator

Product Descriptio

|

MFSC 700W-1500W single-mode continuous fiber laser adopts modular design, the system is highly integrated, maintenance-free and highly reliable. The laser power is continuously adjustable, with high beam quality and high laser stability. It is an ideal laser source for laser fine cutting, precision welding and other applications. Using optical fiber with QBH head output, it can be used with laser processing heads, galvanometers, etc. for system integration with robots, machine tools, etc., and is widely used in 3C, hardware, medical, automotive, aviation and other fields. |

Product Advantages

|

Modular design, stable performance The internal structure adopts the separation design of photoelectric modules, which makes the operation performance more stable. |

|

|

Easy maintenance and reduced downtime Optical modules, electrical modules, control units, and drive units can be directly replaced, upgraded, and maintained on the client side. |

|

Can be customized to meet a variety of needs Users can choose optical fibers with different core diameters according to different processing needs to meet differentiated processing needs. |

|

|

Even light spot energy distribution ensures stable processing Reduce welding spatter and make thick plate cutting ability more stable |

Parameter

| Model | MFSC-1000W | MFSC-1200W | MFSC-1300W | MFSC-1500W |

| Optical properties | ||||

| Output power (W) | 1000 | 1200 | 1300 | 1500 |

| Operating mode | Continuous / Pulse | |||

| polarization state | random | |||

| Power adjustment range (%) | 10~100 | |||

| Center wavelength (nm) | 1080(±10) | |||

| Beam quality M² |

1.3(20u-QBH output) 2.8(50u-QBH output) |

|||

| Output optical cable parameters | ||||

| output method | Standard QBH(LOC) | |||

| Fiber optic cable length (m) | 15 | |||

| Output fiber core diameter (μm) | 50(30/100 optional) | |||

| Optical fiber cable bending radius (mm) | 200 | |||

| Other parameters | ||||

| Working environment temperature (℃) | 10~40 | |||

| cooling method | water cooling | |||

| Overall machine size (mm) | 800×482.6×193.2 | |||

| Overall machine weight (kg) | 50(±3) | |||

For More Details

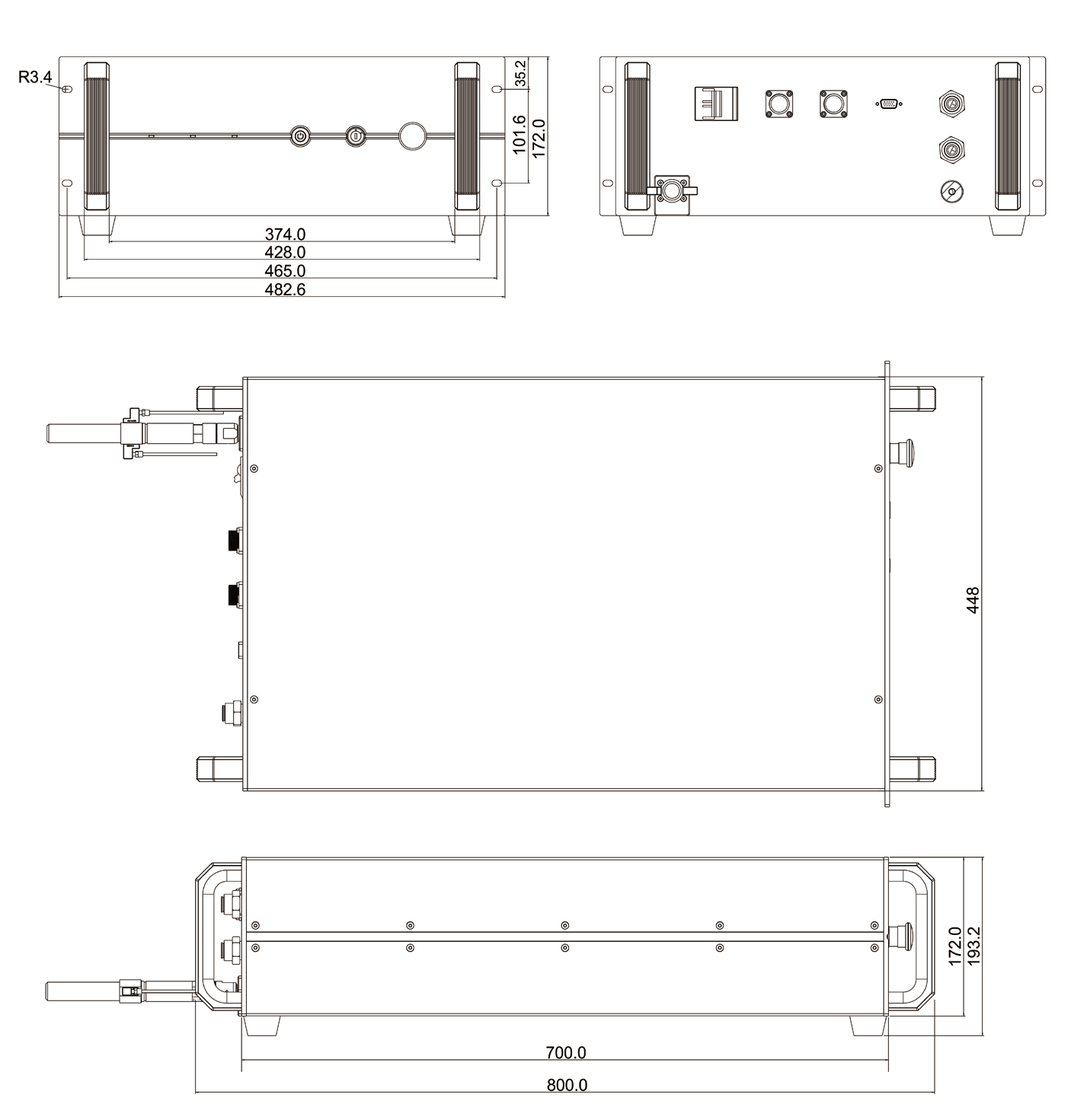

structural layout

Three views of the laser (unit: mm)

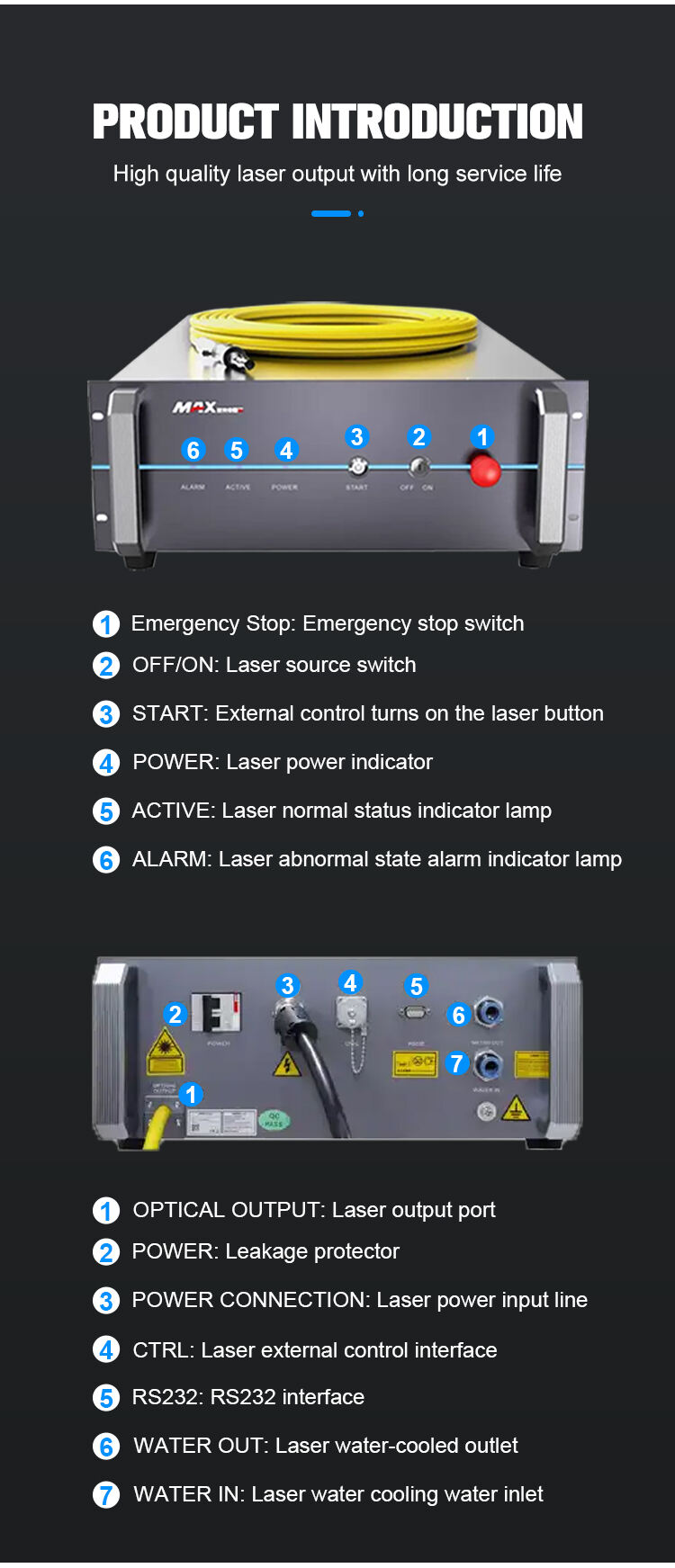

Front panel description

Rear panel description

Package

The packaging of our lasers provides strong protection during transportation and storage, protecting the laser machine from physical damage such as collisions or drops. Its thickness also protects the device from environmental factors such as moisture, heat, and dust, ensuring MAX Laser arrives at the customer's location in optimal condition.

EN

EN

AR

AR CS

CS NL

NL FR

FR DE

DE IT

IT JA

JA KO

KO PL

PL PT

PT RU

RU ES

ES UK

UK TH

TH TR

TR