LSG Series Industrial Wet-Type Deburring and Polishing Line

Description

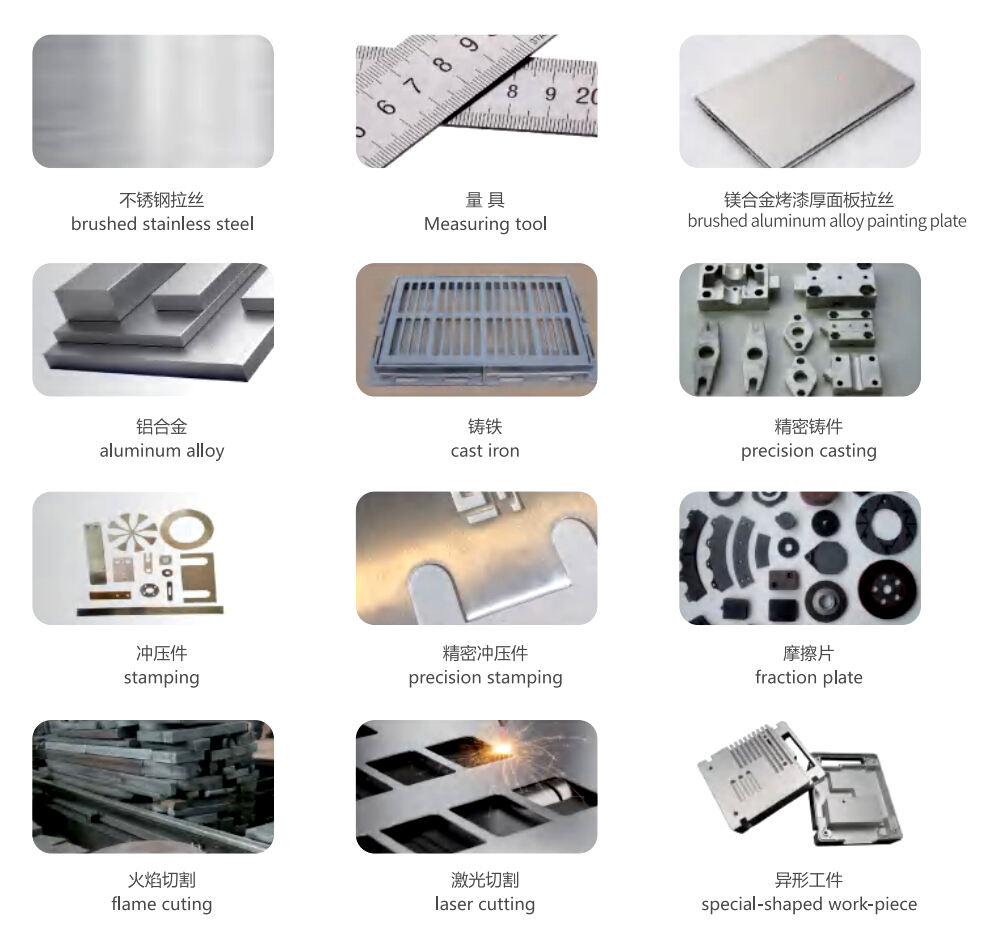

Precision Surface Finishing for Sheet Metal and Composite Panels

The LSG Series wet deburring and polishing machine is engineered for manufacturers demanding clean, consistent, and high-speed surface finishing. It supports a wide range of materials and incorporates a closed-loop wet grinding system with full water treatment and filtration.

Core Benefits

Versatile Surface Treatment: Removes burrs, polishes, and finishes in one streamlined operation.

Enhanced Material Compatibility: Works on steel, stainless steel, aluminum, copper, plastics, titanium, and stone surfaces.

Industrial-Grade Construction: Designed for heavy, continuous use with wide processing widths up to 2200mm.

Clean & Eco-Friendly Operation: Fully integrated wet cooling, filtration, and drying system for safe and sustainable production.

Technical Highlights

| Widths Available | 350mm – 2200mm |

| Thickness Capacity | 1–80mm |

| Abrasive Belt Speed | 12 m/s (inverter controlled) |

| Polishing Wheel Speed | 15 m/min |

| Feed Rate | 2–11 m/min |

| Elevation Precision | 0.01mm (digital display) |

Feeding Systems (Optional)

1.Standard Clamp Conveyor

2.Heavy-Duty Rubber Roller Feeder

3.Permanent Magnetic Conveyor (for carbon steel)

4.Vacuum Conveyor System (for non-ferrous & non-magnetic materials)

Wet System Includes

1.Spray lubrication at each station

2.Entry/exit anti-splash rollers

3.Air knives for moisture removal

4.Three-stage squeeze rollers

5.Auto paper-belt filtration for grinding fluid recycling

Typical Use Cases

High-volume laser/plasma-cut sheet edge finishing

Brushed surface effect on aluminum and stainless panels

Removing oxide scale, scratches, and rolling marks

Pre-coating surface preparation

EN

EN

AR

AR CS

CS NL

NL FR

FR DE

DE IT

IT JA

JA KO

KO PL

PL PT

PT RU

RU ES

ES UK

UK TH

TH TR

TR