LSD Series Wet Deburring & Chamfering Machine

Description

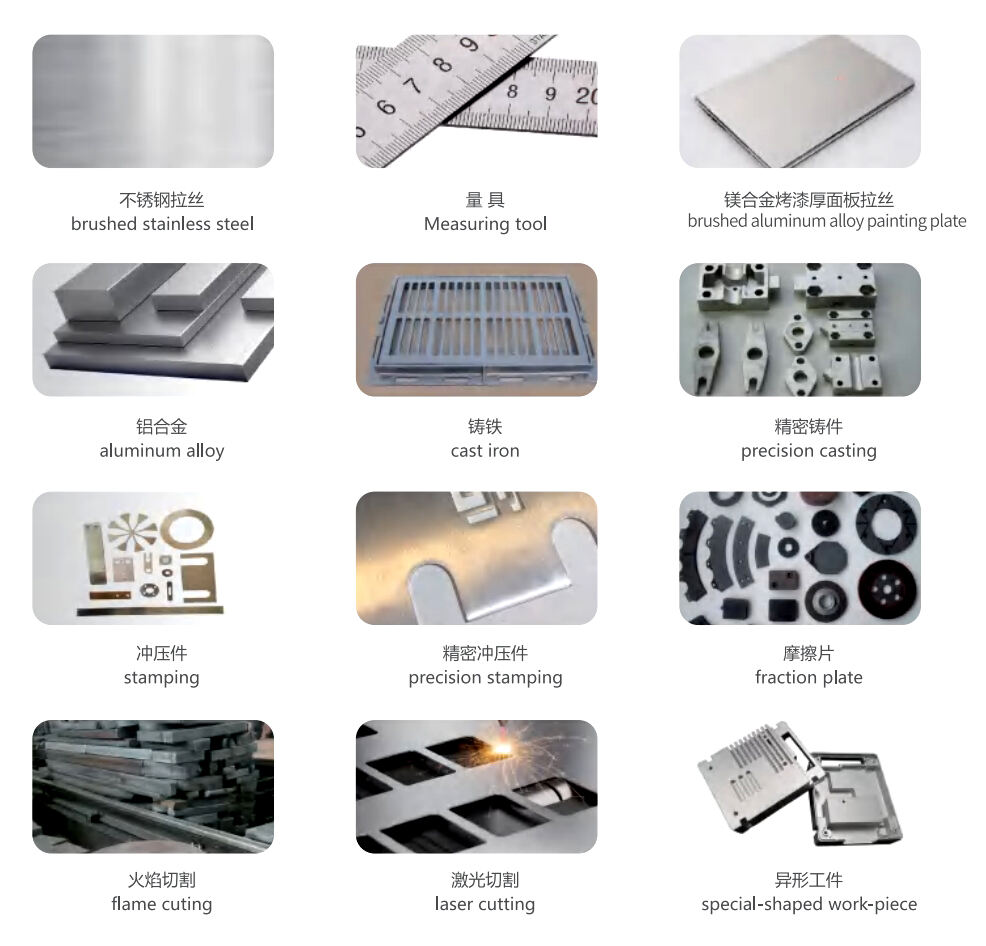

The LSD Series is a specialized wet deburring and edge rounding system designed for precision stamped parts, automotive components, powder metallurgy parts, and gear-like machined items. Engineered for accuracy and surface consistency, this equipment performs wet deburring, R-edge rounding, and chamfering on workpieces with thicknesses from 1mm to 80mm, achieving consistent, high-quality finishes across edges and holes.

This series features planetary disc brush technology, combined with abrasive belt grinding heads in various modular configurations for maximum flexibility.

Features

|

Wet Processing for Superior Surface Quality:

|

|

|

|

|

Customizable Feeding Options:

|

|

Technical Specifications

| Processing Widths | 300mm / 400mm / 650mm / 1050mm / 1350mm |

|---|---|

| Workpiece Thickness | 1–80mm |

| Abrasive Belt Speed | 12m/s (frequency adjustable optional) |

| Disc Brush Rotation Speed | 800–1500rpm (optional frequency control) |

| Disc Group Revolution | 50–150rpm (frequency adjustable) |

| Disc Brush Oscillation | 120–280 times/min (adjustable) |

| Feeding Speed | 0.5–6m/min (frequency adjustable) |

Disc Brush Configurations by Width

300mm: 3 planetary disc brushes – individual rotation + group revolution

400mm: 4 planetary disc brushes

650mm: 5 staggered disc brushes – adjacent brushes rotate in opposite directions with lateral oscillation

1050mm: 7 staggered disc brushes with full oscillation

1350mm: 9 staggered disc brushes with full oscillation

Applications

The LSD Series is ideal for:

Precision stamped components

Automotive parts

Gear parts & mechanical surfaces

Powder metallurgy items

Deburring edges and holes to a uniform R-radius

Pre-finishing of burr-prone materials

|

|

EN

EN

AR

AR CS

CS NL

NL FR

FR DE

DE IT

IT JA

JA KO

KO PL

PL PT

PT RU

RU ES

ES UK

UK TH

TH TR

TR