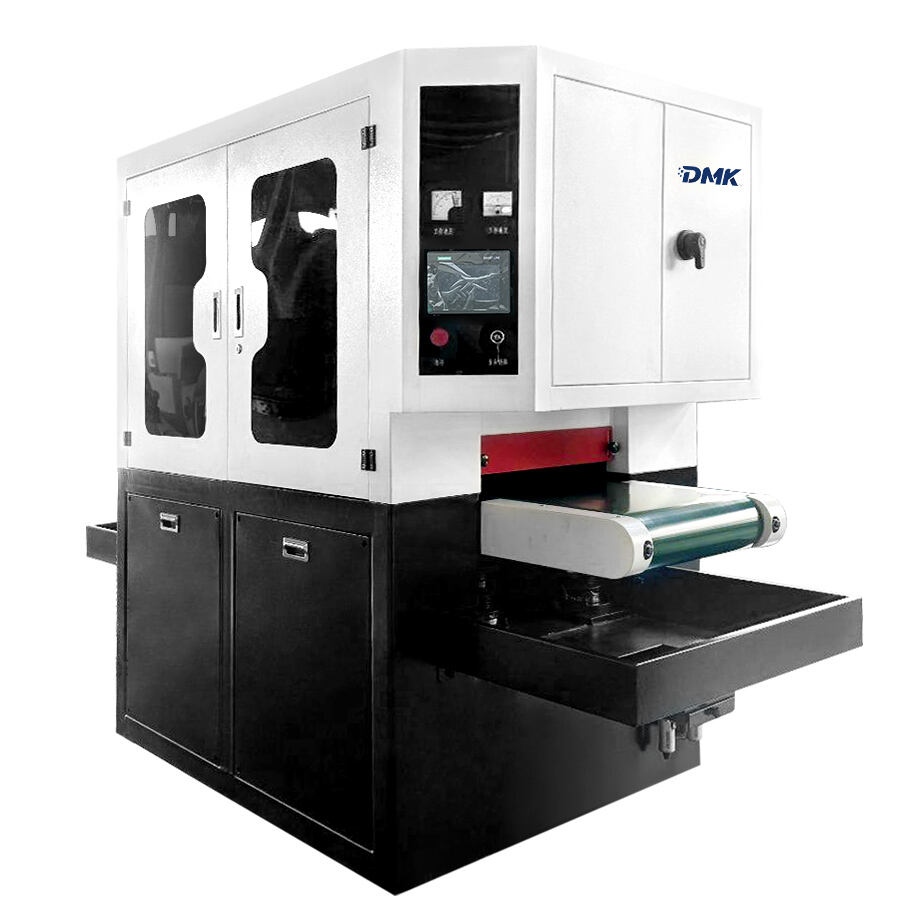

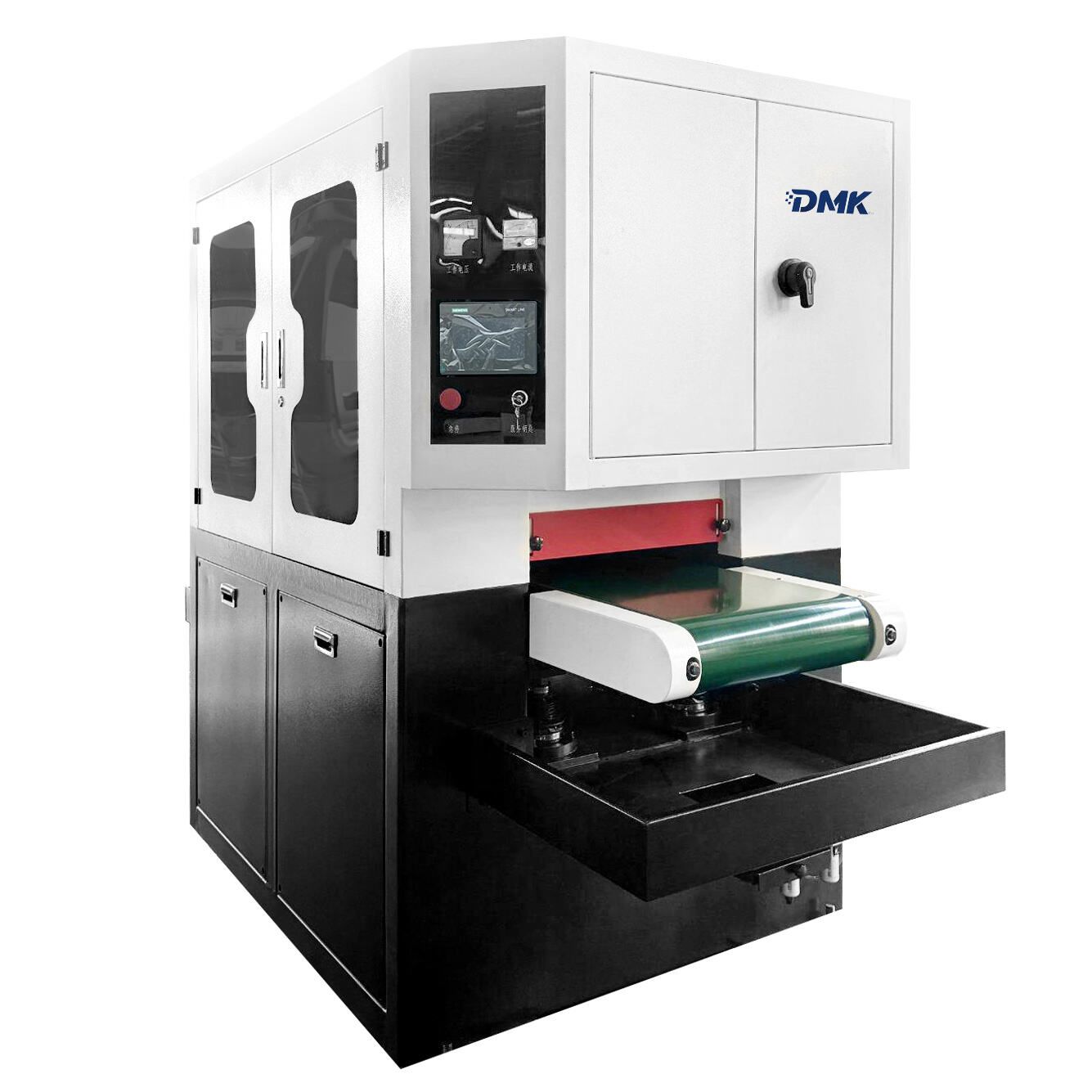

LSD Series Dry Deburring / Edge Rounding / Polishing Machine

Product Description

The LSD Series is a high-efficiency dry-type deburring and surface finishing machine, designed for precision treatment of punched parts, gear components, automotive metal parts, powder metallurgy products, and machined metal workpieces. This system is built for edge rounding, hole deburring, surface brushing, and polishing, producing consistent R-radius edges and uniform finishes.

Available in multiple working widths (300–1350mm), the LSD Series features abrasive belt stations and planetary disc brush modules in flexible configurations to match your production needs. Its dry processing design eliminates the need for grinding fluids, providing a cleaner and more cost-effective solution for metal surface treatment.

Key Features

|

Dry Processing System

|

|

|

|

|

Precision Height Adjustment

|

|

|

Multiple Feeding Options

|

Technical Specifications

| Model Width Options | 300mm / 400mm / 650mm / 1050mm / 1350mm |

|---|---|

| Processing Thickness | 1–80mm |

| Abrasive Belt Speed | 12m/s (with optional variable frequency) |

| Disc Brush Rotation Speed | 800–1500 rpm (adjustable) |

| Disc Group Revolution Speed | 50–150 rpm (adjustable) |

| Brush Group Oscillation | 120–280 cycles/min (adjustable) |

| Feeding Speed | 0.5–6 m/min (frequency adjustable) |

| Height Adjustment Accuracy | ±0.01mm digital readout |

Disc Brush Configuration per Model

300mm: 3 planetary-arranged disc brushes

400mm: 4 planetary disc brushes

650mm: 5 staggered brushes (alternating reverse rotation + lateral oscillation)

1050mm: 7 staggered brushes

1350mm: 9 staggered brushes

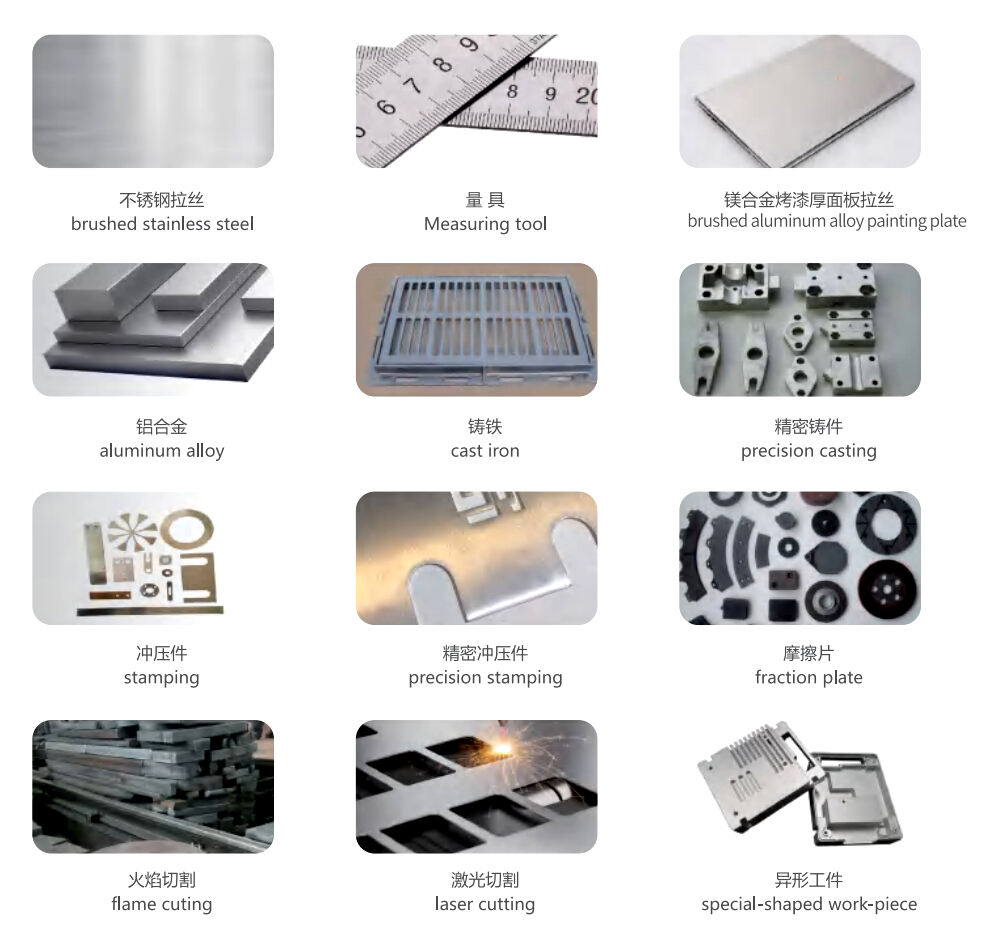

Applications

The LSD Series Dry Deburring Machine is widely used for:

Precision Stamped Parts

Automotive Metal Components

Powder Metallurgy Workpieces

Machined Gears and Small Parts

Edge Chamfering, Hole Deburring, R-edge rounding

Surface Polishing and Linear Brushing

This machine is ideal for dry-processing production lines in automotive, electronics, metal stamping, gear manufacturing, and mechanical part assembly industries.

EN

EN

AR

AR CS

CS NL

NL FR

FR DE

DE IT

IT JA

JA KO

KO PL

PL PT

PT RU

RU ES

ES UK

UK TH

TH TR

TR