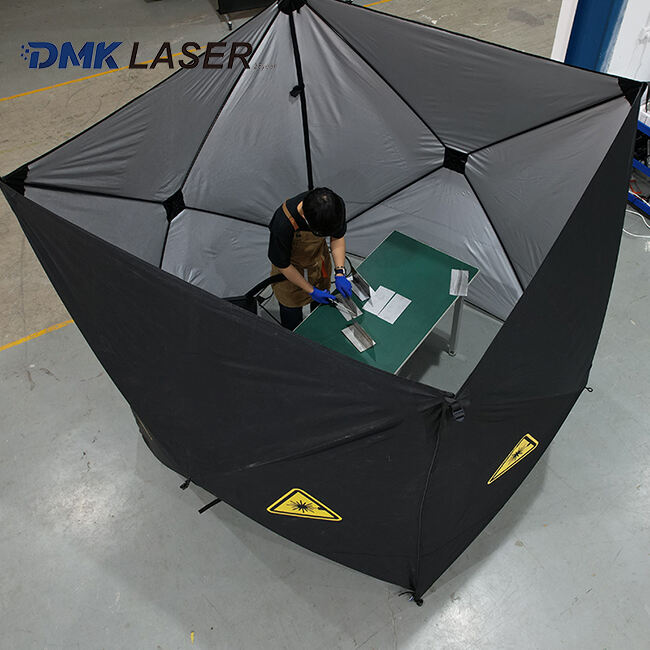

Laser Protection Foldable Tent

This laser protection foldable tent is a professional protective equipment specially designed for laser operation scenarios. With high-strength fabric as the main body and lightweight yet durable support structure, it can be quickly set up to form a closed or semi-closed protective space. It effectively blocks laser radiation while balancing portability and stability, providing safe and reliable protection for laser processing, experiments and other operations.

Production Parameters

Component Name |

Base Material / Material |

Process / Configuration |

Performance Features |

Key Parameters |

Tent Fabric |

500D Polyester Oxford Cloth |

Silver coating process; single-sided silver coating for black version |

Fire-retardant (enhanced for black version), lightweight and tough |

Thickness: 0.25MM±0.03; Weight: 8kg |

Metal Components |

Aluminum Alloy |

- |

Waterproof, moisture-proof and wear-resistant; ensuring durability of support structure |

- |

Support Components |

Composite of Glass Fiber and Synthetic Resin |

Equipped with 8 rigid fiber rods |

Lightweight, corrosion-resistant and insulating |

- |

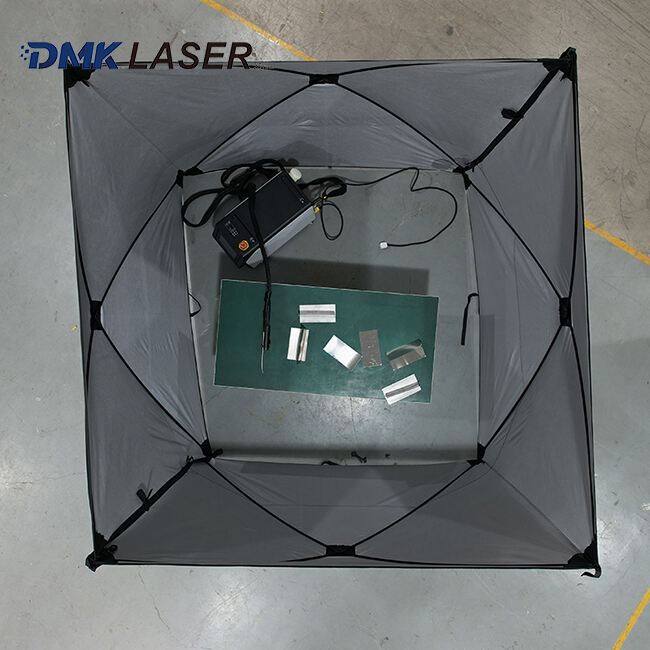

Single Panel Tent Dimension |

2m × 2m ±0.1 |

- |

- |

Meets standard operation space requirements |

Complete Product Composition |

- |

1 set of 2m×2m×2m square tent fabric, 2 sets of Harper 7 kits, 8 rigid fiber rods |

Regular cubic protective area |

Forms closed protective space |

Product Features

Professional Laser Protection: The silver coating process combined with fire-retardant fabric effectively blocks laser radiation. The flame-retardant function reduces fire risks during operations, providing dual protection for personnel and the environment.

Lightweight & Portable: With a total weight of only 8kg, the fiber rods and aluminum alloy components are lightweight. The entire equipment is easy to carry and store, facilitating quick on-site deployment.

Durable & Wear-Resistant: 500D polyester Oxford cloth is wear-resistant and tear-resistant; aluminum alloy components are waterproof and moisture-proof; fiber rods are corrosion-resistant and insulating. It adapts to various operating environments and extends service life.

Product Applications

Industrial Laser Processing Scenarios: Suitable for workshop operations such as laser cutting, welding and marking. It isolates laser radiation for operators and demarcates safe operation areas.

Laser Experimental Research Fields: Can be used as a temporary protective barrier in laboratories for scenarios like laser physics experiments and material property analysis, ensuring the safety of the experimental process.

Outdoor Laser Operation Scenarios: With its waterproof and moisture-proof structural design, it meets the operational needs of outdoor portable laser equipment, such as on-site laser repair and laser testing for field exploration.

EN

EN

AR

AR CS

CS NL

NL FR

FR DE

DE IT

IT JA

JA KO

KO PL

PL PT

PT RU

RU ES

ES UK

UK TH

TH TR

TR