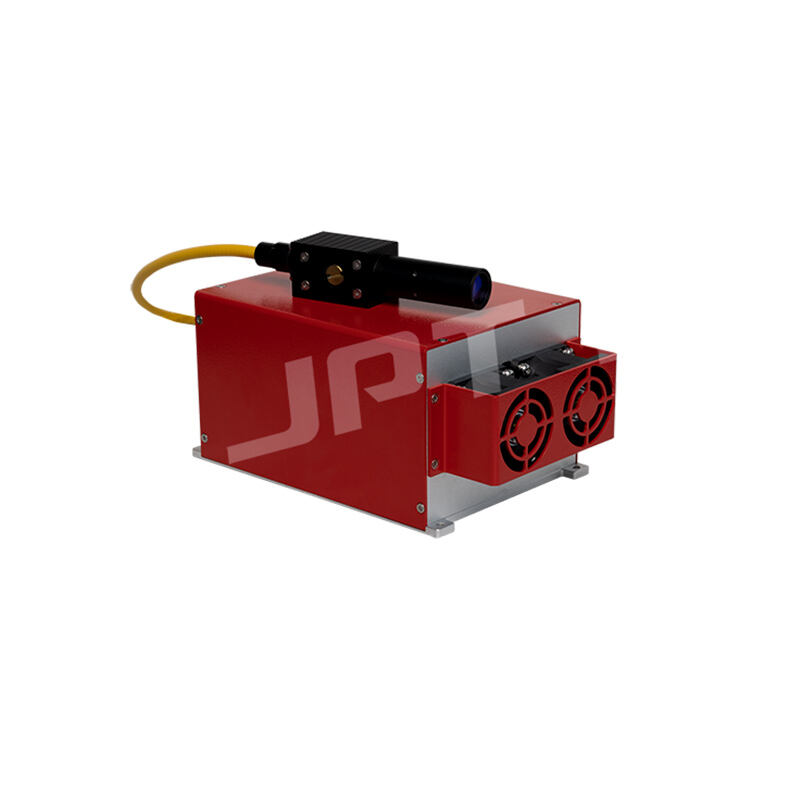

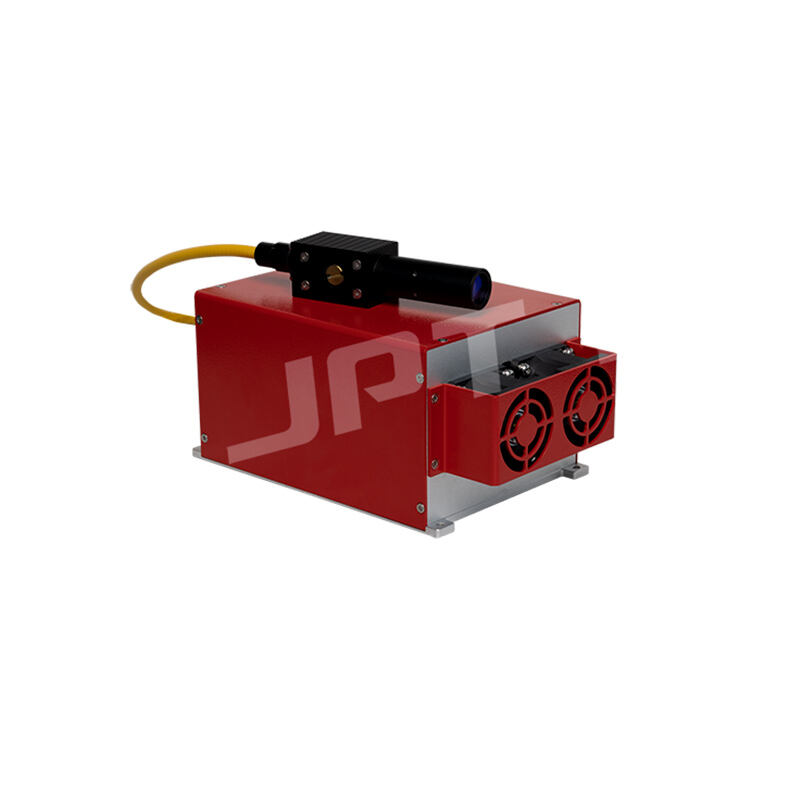

JPT M7 Series 60W / 100W MOPA Fiber Laser Source

Product Overview

The JPT M7 Series 60W and 100W MOPA fiber lasers are high-power solutions engineered for demanding industrial applications. Built on MOPA (Master Oscillator Power Amplifier) architecture, these lasers use a directly modulated semiconductor seed source for precise pulse control, offering independent adjustment of pulse width and frequency.

Compared to traditional Q-switched lasers, the M7 series delivers superior performance—higher peak power, cleaner pulse shaping, and broader material compatibility. Whether you're cutting, deep engraving, welding, or performing surface treatments, the M7 60W and 100W models deliver speed, stability, and exceptional results.

Key Features

| ✅ High Output Power: 60W and 100W versions for more intensive, high-speed industrial processing. |  |

|

✅ Independent Pulse Frequency & Width Control: Allows precise tuning to match specific materials and processing needs. |

| ✅ Stable High Peak Power Output: Ensures consistent results even in high-speed or deep-processing tasks. |  |

|

✅ Pulse On Demand (POD) Mode: Real-time pulse triggering for dynamic and high-speed marking scenarios. |

| ✅ Advanced MOPA Technology: Flexible pulse shaping enables a wide range of applications and superior surface finishes. |  |

Product Parameters

| Series Model |

YDFLP-E2- 60-M7-M-R |

YDFLP-E- 100-M7-M-R |

|

| Beam quality (M²) | / | <1.5 | <1.6 |

| Armored cable length | m | 3 | |

| Average output power | W | 60 | 100 |

| Maximum pulse energy | mJ | 2 | 1.5 |

| Frequency adjustable range | kHz | 1~4000 | |

| Pulse Width | ns | 2~500 | |

| Output power instability | % | <5 | |

| Cooling method | / | Air-cooling | |

| Operating voltage | V | 24 (DC) | |

| Maximum power consumption | W | 95 | 110 |

| Ambient supply current | W | ≥280 | ≥450 |

| Central wavelength | nm | 1064 | |

| Spectrum width@3dB | nm | <15 | |

| Beam diameter | nm | 7.0±1.0 | |

| Power adjustment range | % | 0~100 | |

| Operating temperature range | ℃ | 0~40 | |

| net weight | kg | 4.1 | 8.2 |

| Size(L×W×H) | % | 253.3 × 205 × 75 | 336 × 255 × 90 |

Application

High-Speed, Deep Engraving: Ideal for deep marking on metals and hard plastics.

Precision Thin Sheet Cutting & Spot Welding: Clean, burr-free cuts with minimal heat-affected zones.

Laser Cleaning & Rust Removal: Efficiently removes contaminants, coatings, and oxides.

Surface Texturing & Coating Removal: High control for delicate and uniform surface treatments.

Flying Marking on Production Lines: Seamless integration for on-the-fly engraving and coding.

Available Models:

🔸 M7-60W: Excellent for medium to high-volume applications with enhanced depth and processing speed.

🔸 M7-100W: Designed for high-speed, heavy-duty industrial marking, deep engraving, and surface treatment.

Typical Applications:

Metal Parts Processing

Automotive and Aerospace Components

Electronic Devices and Battery Marking

Tools, Dies, and Molds

Surface Cleaning and Paint Removal

Deep Barcode or Serial Number Engraving

EN

EN

AR

AR CS

CS NL

NL FR

FR DE

DE IT

IT JA

JA KO

KO PL

PL PT

PT RU

RU ES

ES UK

UK TH

TH TR

TR