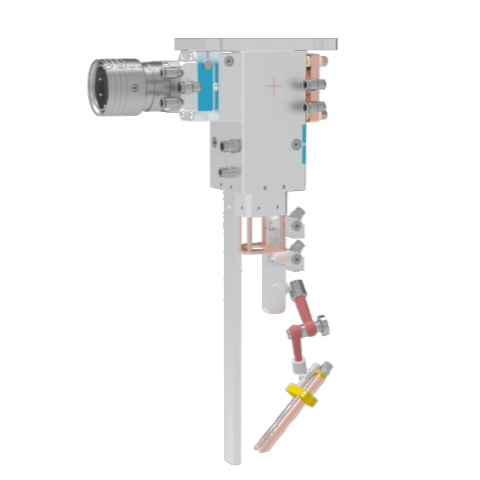

HQ-W-20R 20kW Spot-Ring Spot Welding Head

The HQ-W-20R is a 20kW-class high-power welding device launched by Huaqin Laser. It adopts a spot-ring spot design and full-range water cooling protection, supports customizable spot energy, is compatible with multiple fiber connectors, and features dust resistance and easy maintenance. It is specifically built for medium-low power welding scenarios of thick plates and high-reflectivity materials.

Product Features

- 20kW Stable Operation: Compatible with 20kW high-power laser systems, paired with full-range water cooling protection to ensure continuous welding stability.

- Customizable Spot: Red-blue light spot-ring energy ratio can be customized to meet welding process requirements above the 10,000-watt class.

- High Dust-Proof Design: Effectively isolates dust from lens contact, reduces wear, and significantly extends the service life of optical components.

- Modular & Easy Maintenance: Adopts a modular structure for convenient lens disassembly and assembly, enabling efficient daily maintenance operations.

- Multi-Layer Protection Structure: Equipped with upper protective mirror, double lower protective mirrors, and copper baffle to enhance protection for optical components.

- Multi-Connector Compatibility: Compatible with mainstream fiber connectors such as QBH and QDE, adapting to different laser systems.

Product Parameter Table

| Parameter Item | Specification Details |

|---|---|

| Product Model | HQ-W-20R |

| Maximum Power | 20kW |

| Collimation Focal Length | 150 (Customizable) |

| Focus Focal Length | 300 (Customizable) |

| Fiber Connector | QBH, QDE, etc. |

| Weight | ≤8Kg |

| Light Aperture | φ50 |

| Upper Protective Mirror Size | 30*2 |

| Lower Protective Mirror Size | 50*2 |

| Cooling Method | Full-range water cooling |

Product Application Fields

- Welding of medium-thick metal components

- Welding of high-reflectivity materials (aluminum, copper)

- Welding of small and medium-sized equipment structural parts

- 20kW-class laser welding scenarios

- Precision component welding processing

EN

EN

AR

AR CS

CS NL

NL FR

FR DE

DE IT

IT JA

JA KO

KO PL

PL PT

PT RU

RU ES

ES UK

UK TH

TH TR

TR