HiNest Smart Nesting Software Powered by Industry 4.0

Product Description

Revolutionize your sheet cutting workflow with HiNest, an intelligent nesting software built for full integration in Industry 4.0 smart manufacturing environments. Combining powerful automation with flexible, user-friendly design, HiNest delivers unmatched precision, efficiency, and control across your entire cutting process.

Advantages

Open Interface, Easy Operation

Designed with an intuitive, open-operation interface that makes learning and operating the software effortless.Independent Core Algorithms

Proprietary algorithms ensure high compatibility with various ERP systems, supporting seamless data exchange.Smart Cloud Nesting

Enjoy flexible, on-demand feature combinations and a smoother user experience with cloud-based nesting.Real-Time Data Management

Track and manage nesting data in real time for increased visibility and confidence in production.Advanced Sheet Coordination

Automatically match and mix different materials, with clear, synchronized display of nesting outcomes.Oversized Parts Cutting

Supports nesting on spliced plates, enabling precise cutting of extra-large components.Leftover Sheet Optimization

Manage remaining materials efficiently and re-nest freely to reduce waste.Paperless Operation

Fully supports smart workshop integration with digital workflows and paperless cutting instructions.AGV-Compatible Smart Sorting

Incorporates intelligent sorting algorithms that integrate seamlessly with AGV systems.Comprehensive Reporting

Export a variety of work reports with one click to simplify production and material management.Material Budgeting & Procurement Planning

Includes budgeting tools to support purchasing strategies and reduce material costs.Re-nesting Optimization

Allows secondary nesting to refine cutting layouts or reassign parts efficiently.Material Traceability

Built-in tracking features ensure consistent material information across production cycles.

Main Functions

|

|

|

|

|

|

Software Display

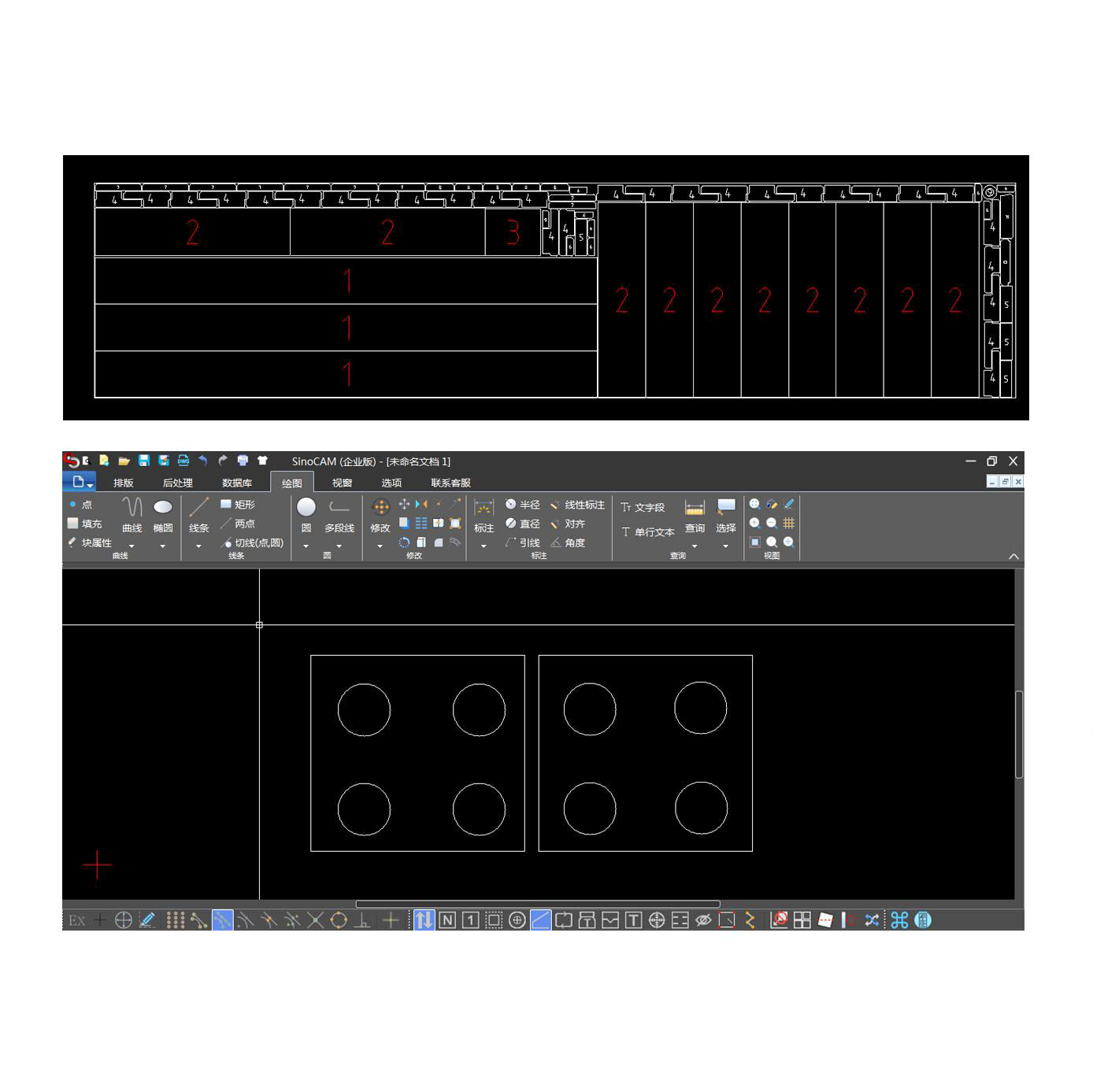

|

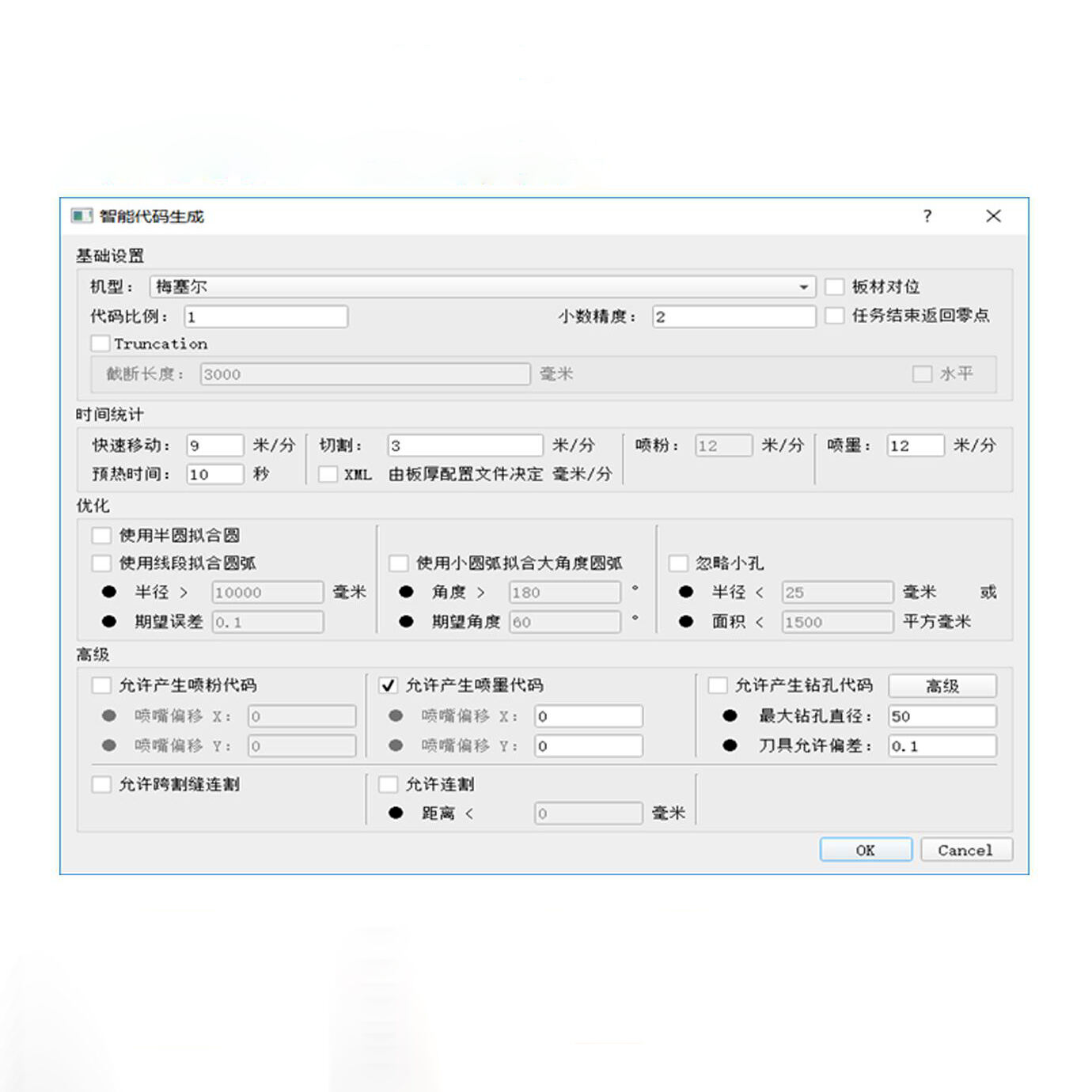

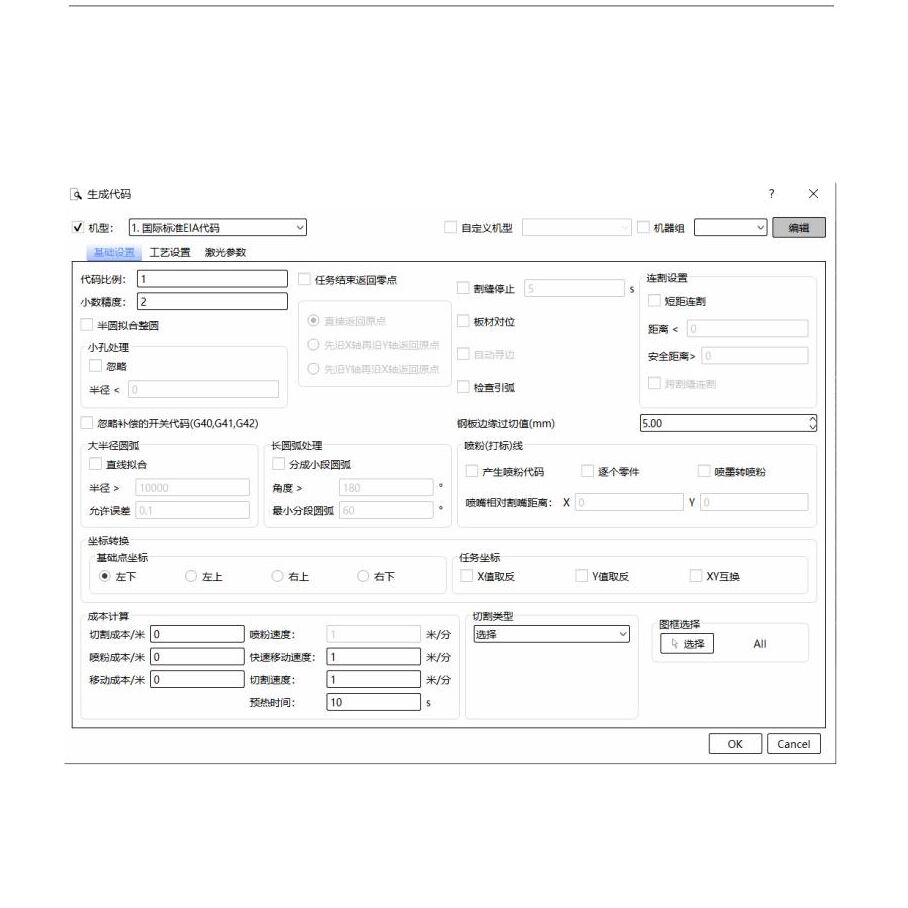

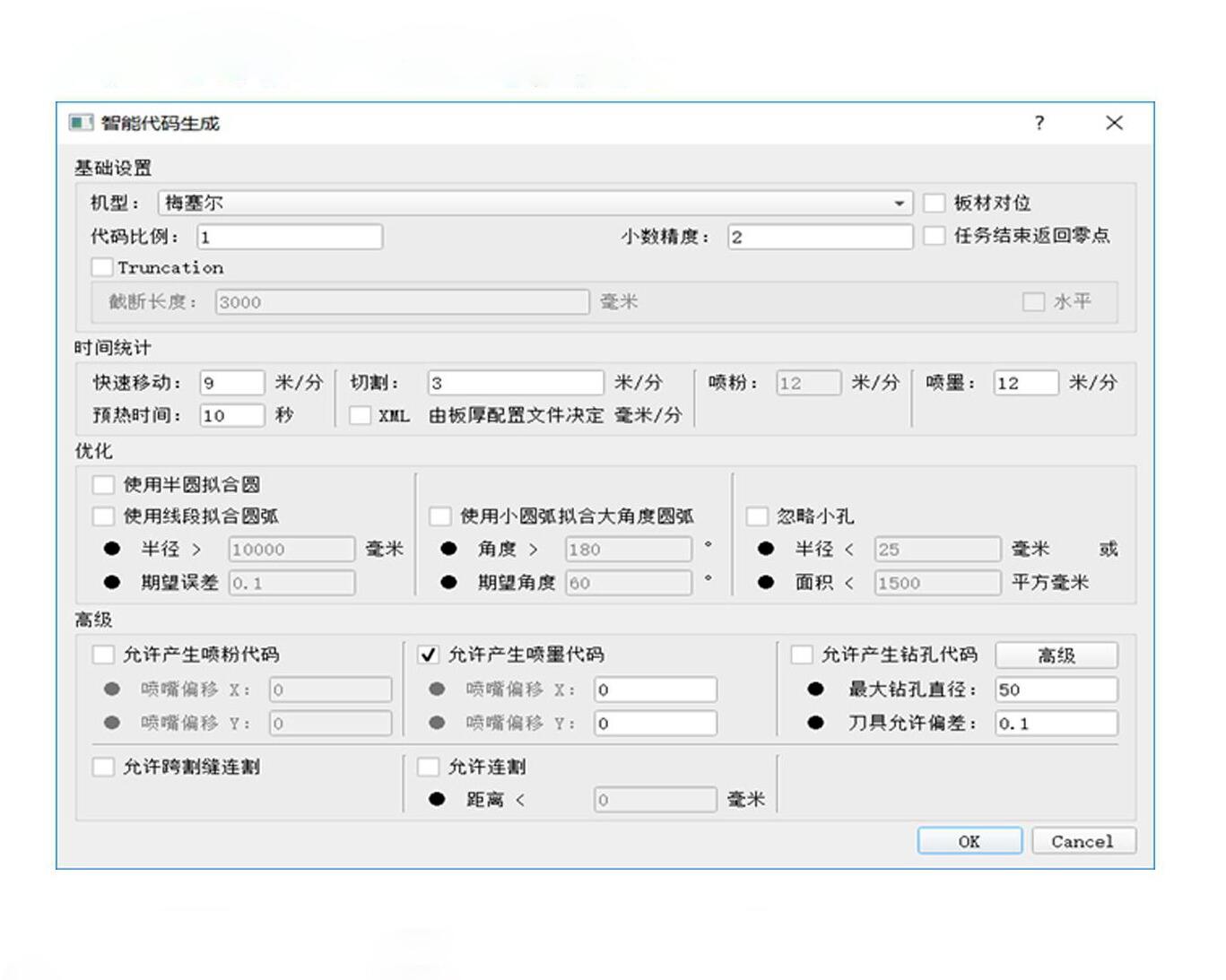

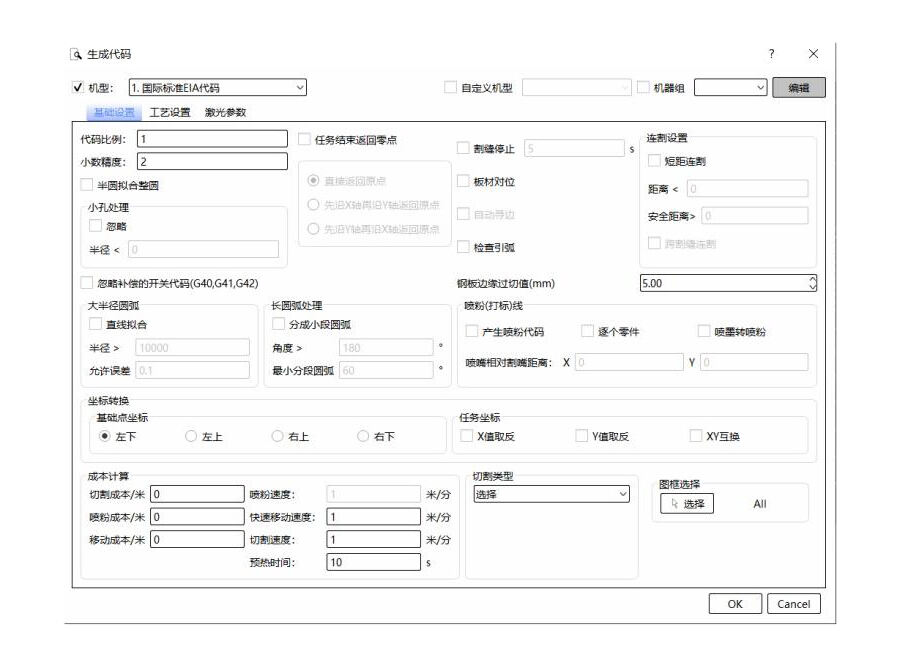

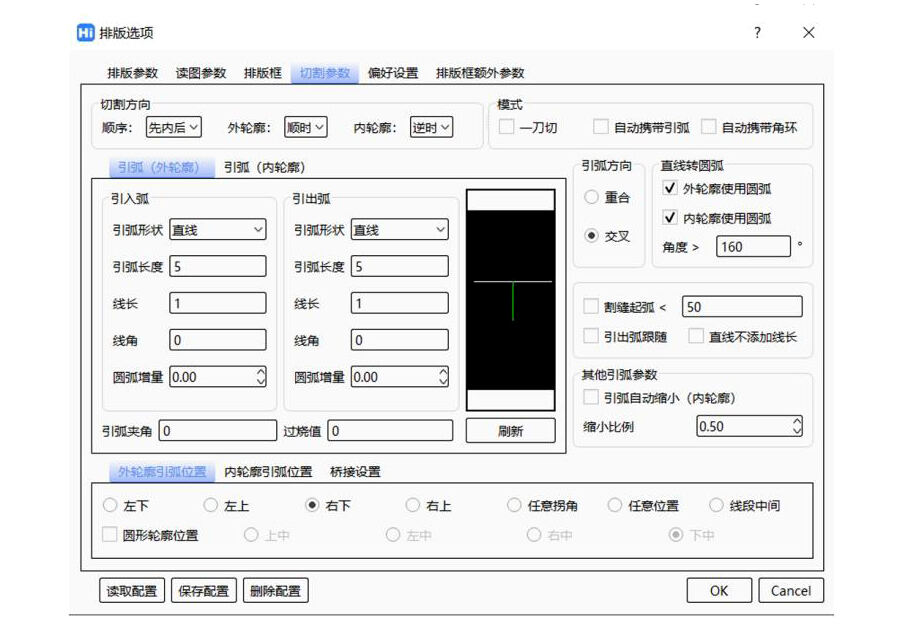

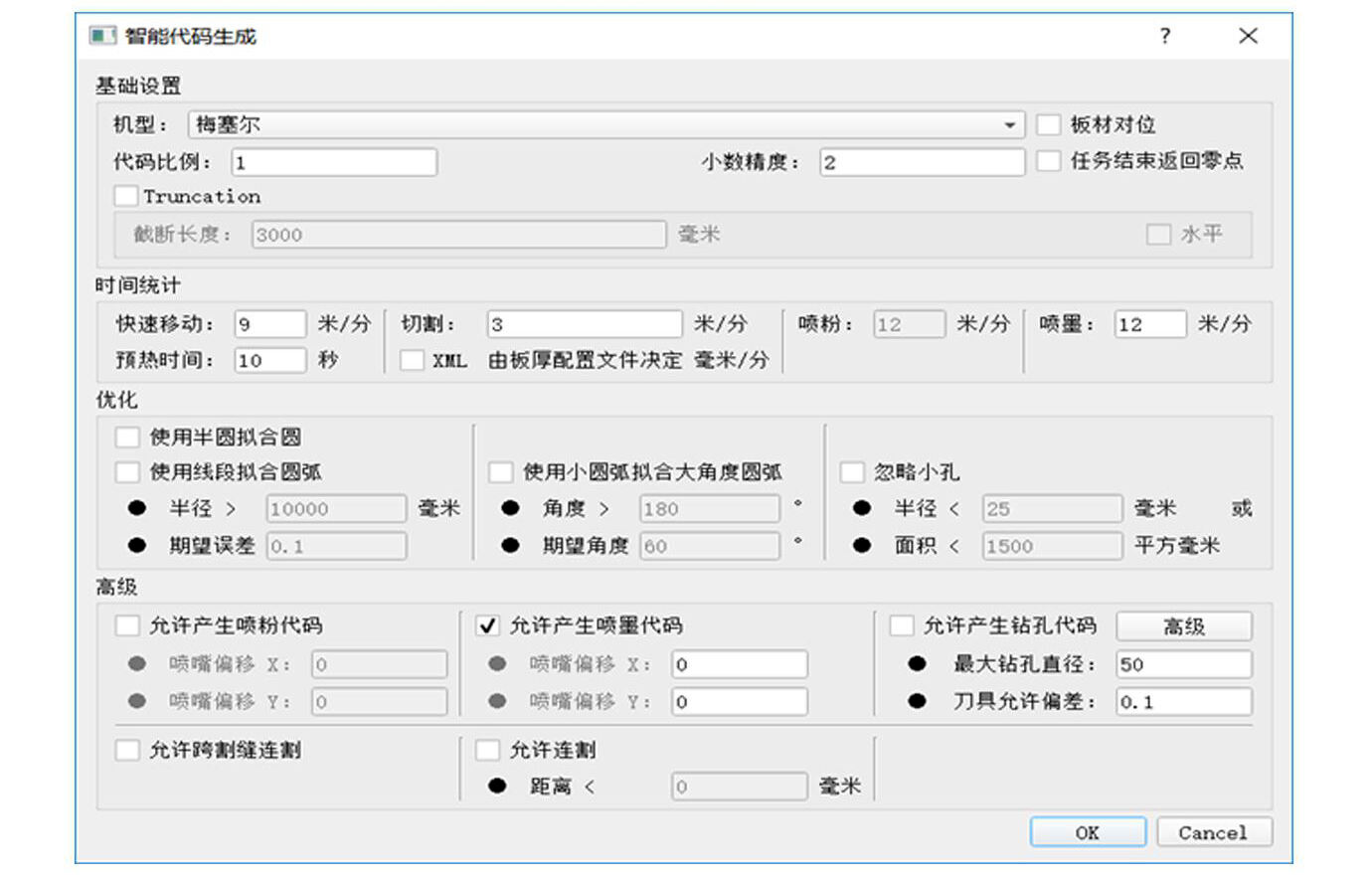

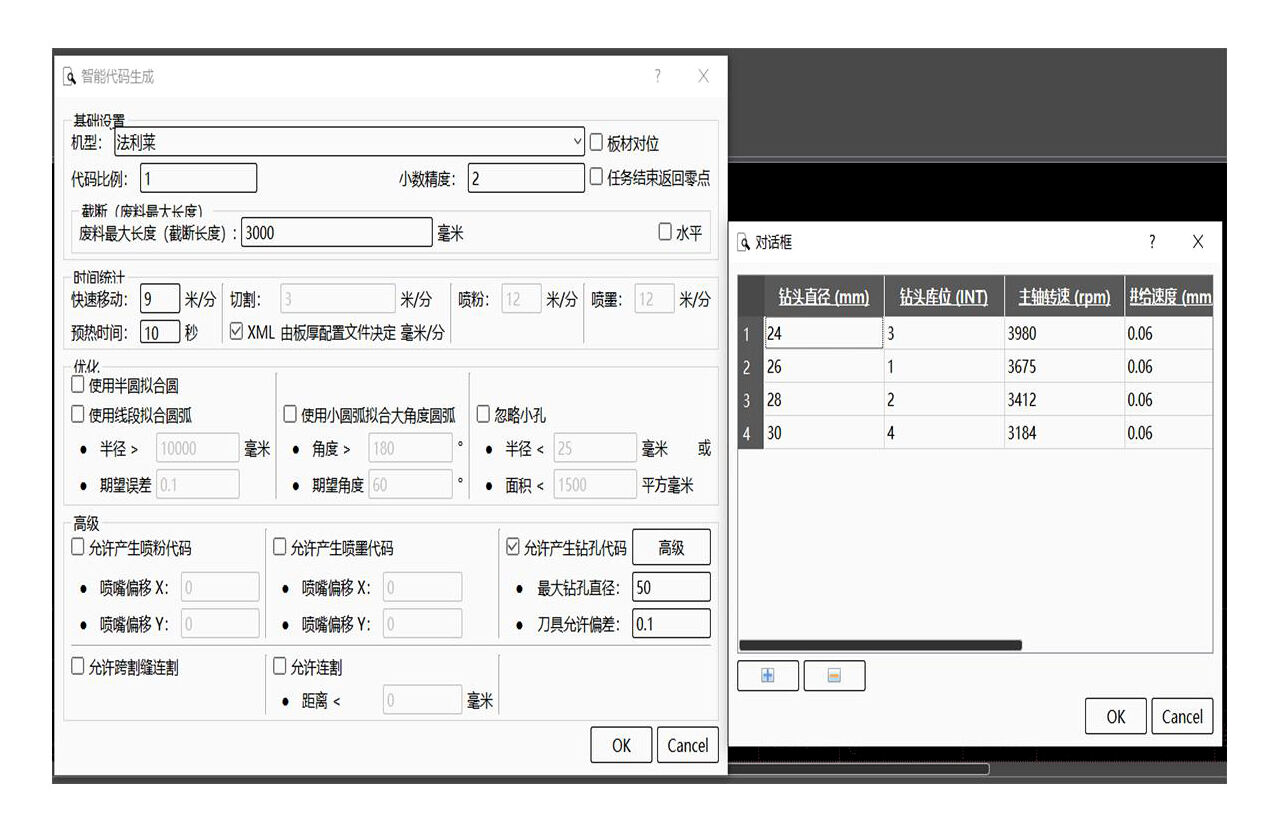

Custom Code Output The software supports all cutting machine tool code file extensions and can automatically generate CNC codes that can be recognized by various CNC machines. |

|

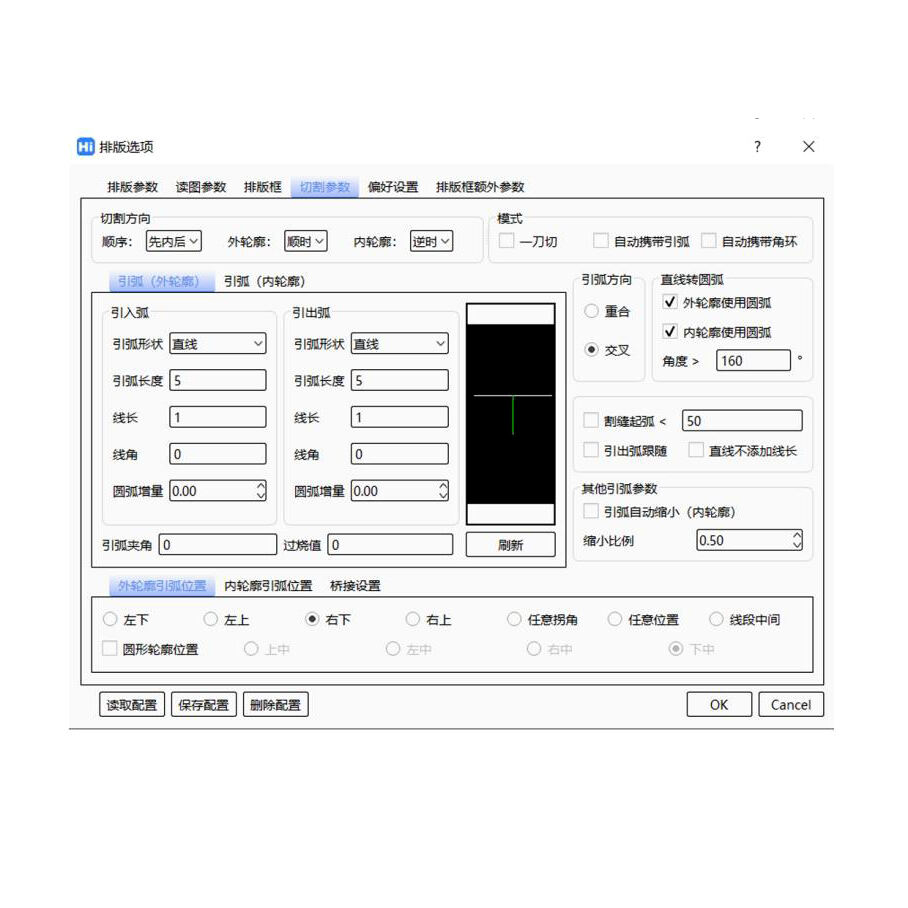

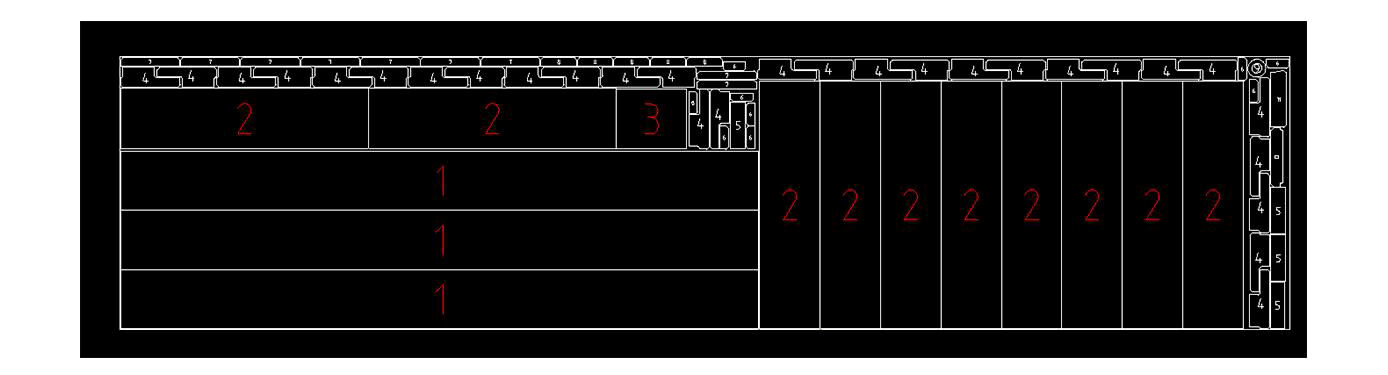

Common Edge Cutting The software has a part common edge function. The common edge operation uses a pull-in mode, allowing you to perform common edge operations on any part, or you can complete the common edge operation for a batch of parts at once. The operation is intuitive and simple, resulting in better nesting efficiency. |

|

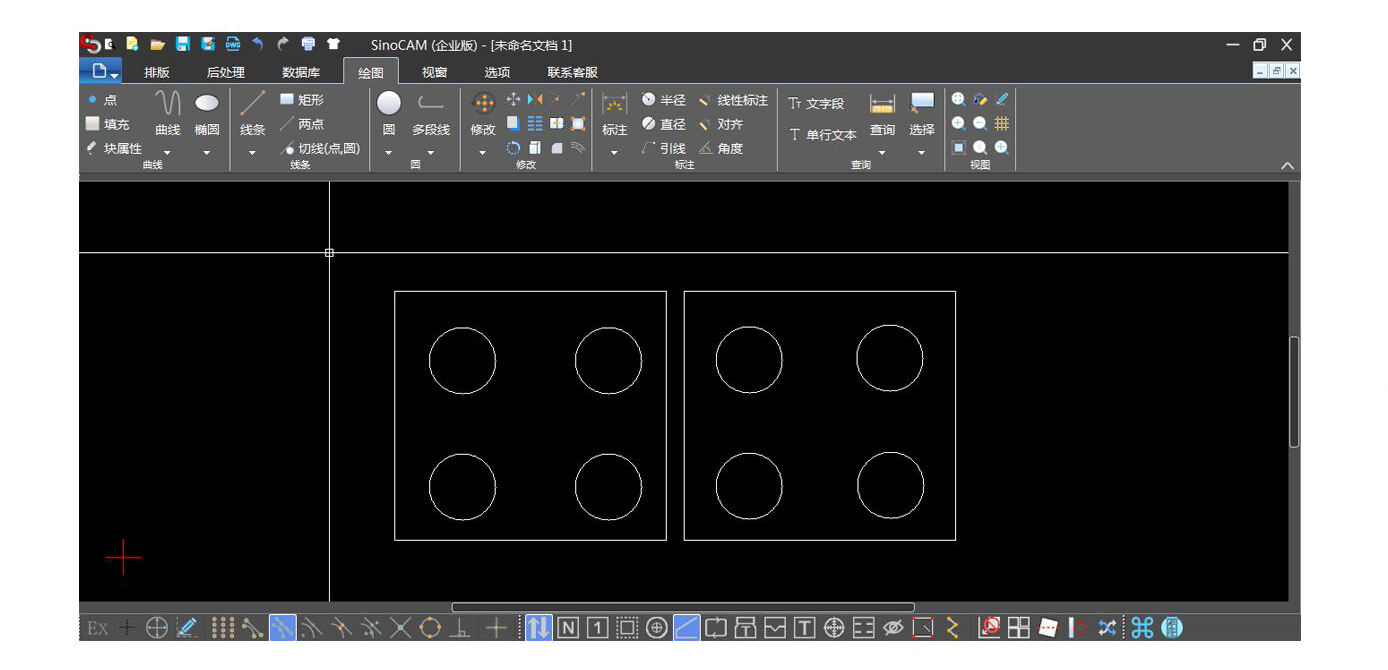

Drawing Function 2D drawing software with a standard operating interface, supports storing drawings as DWG/DXF files. You can also import pre-arranged files for editing. |

|

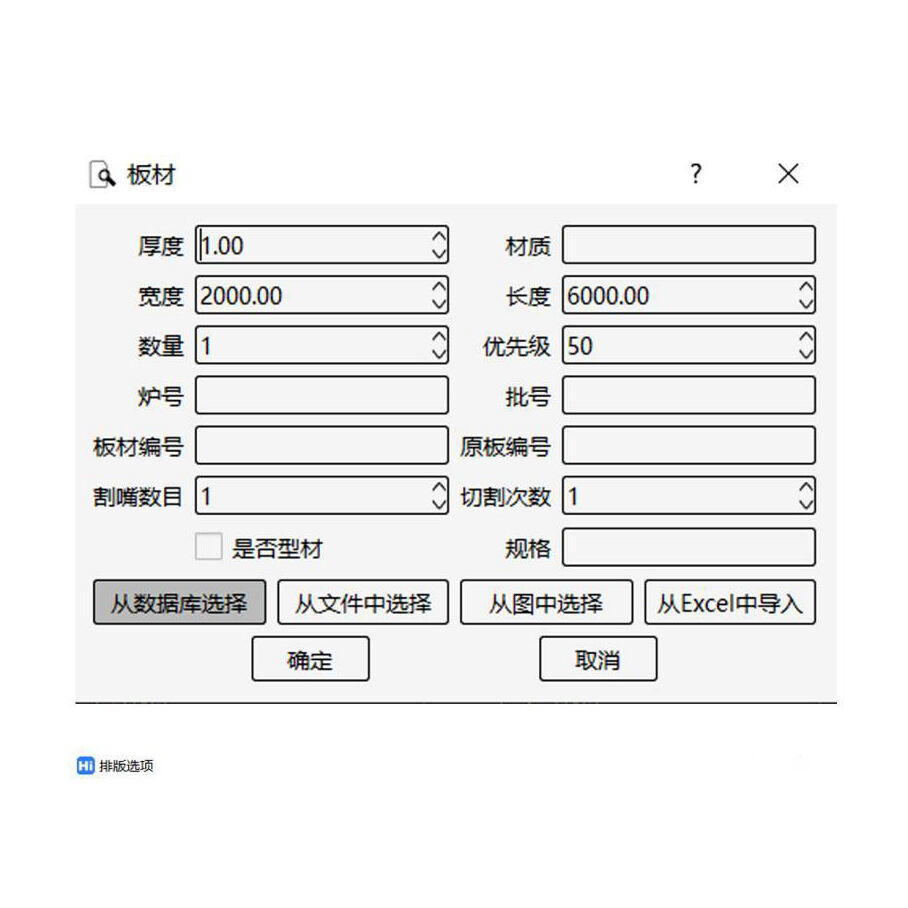

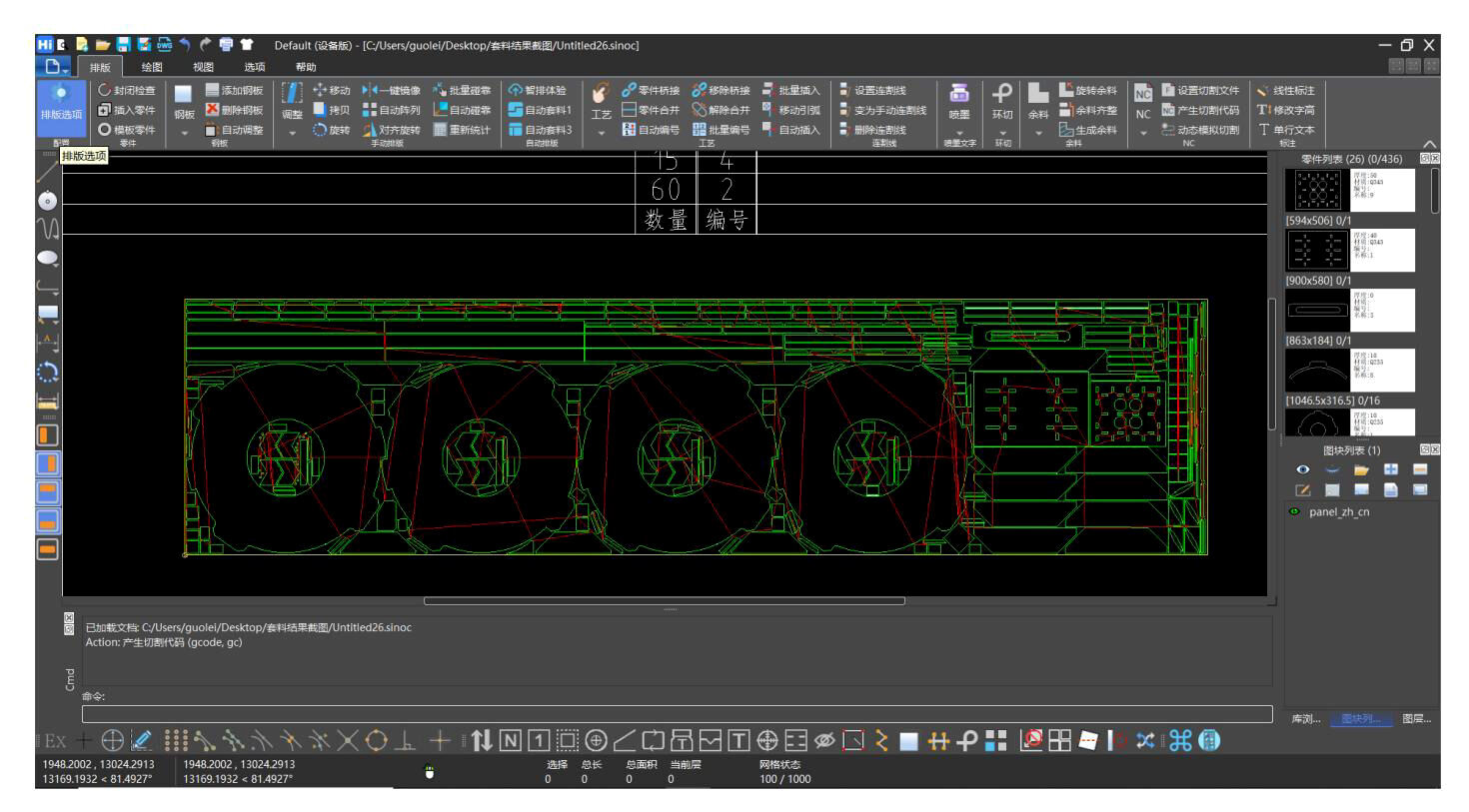

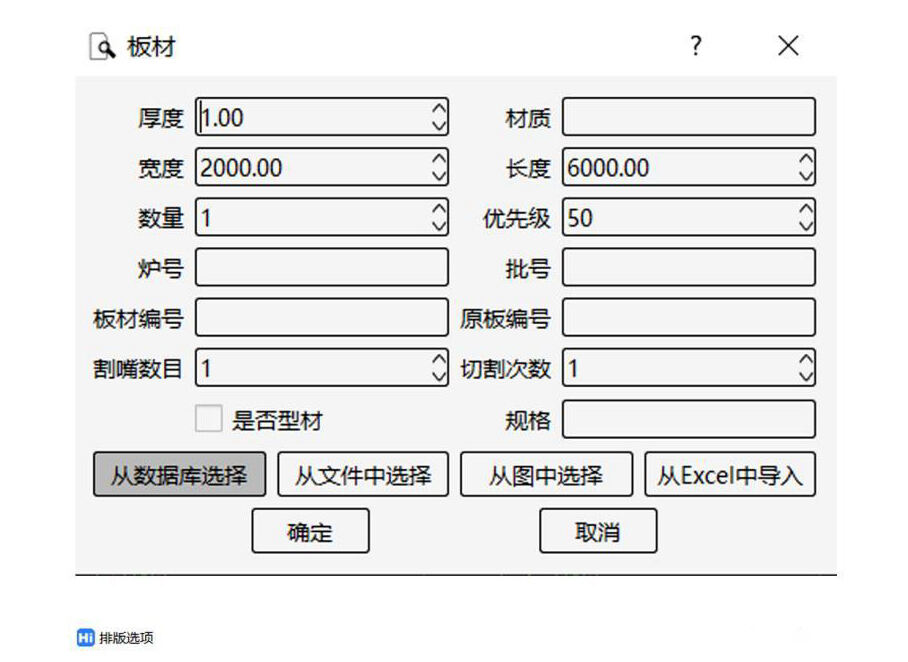

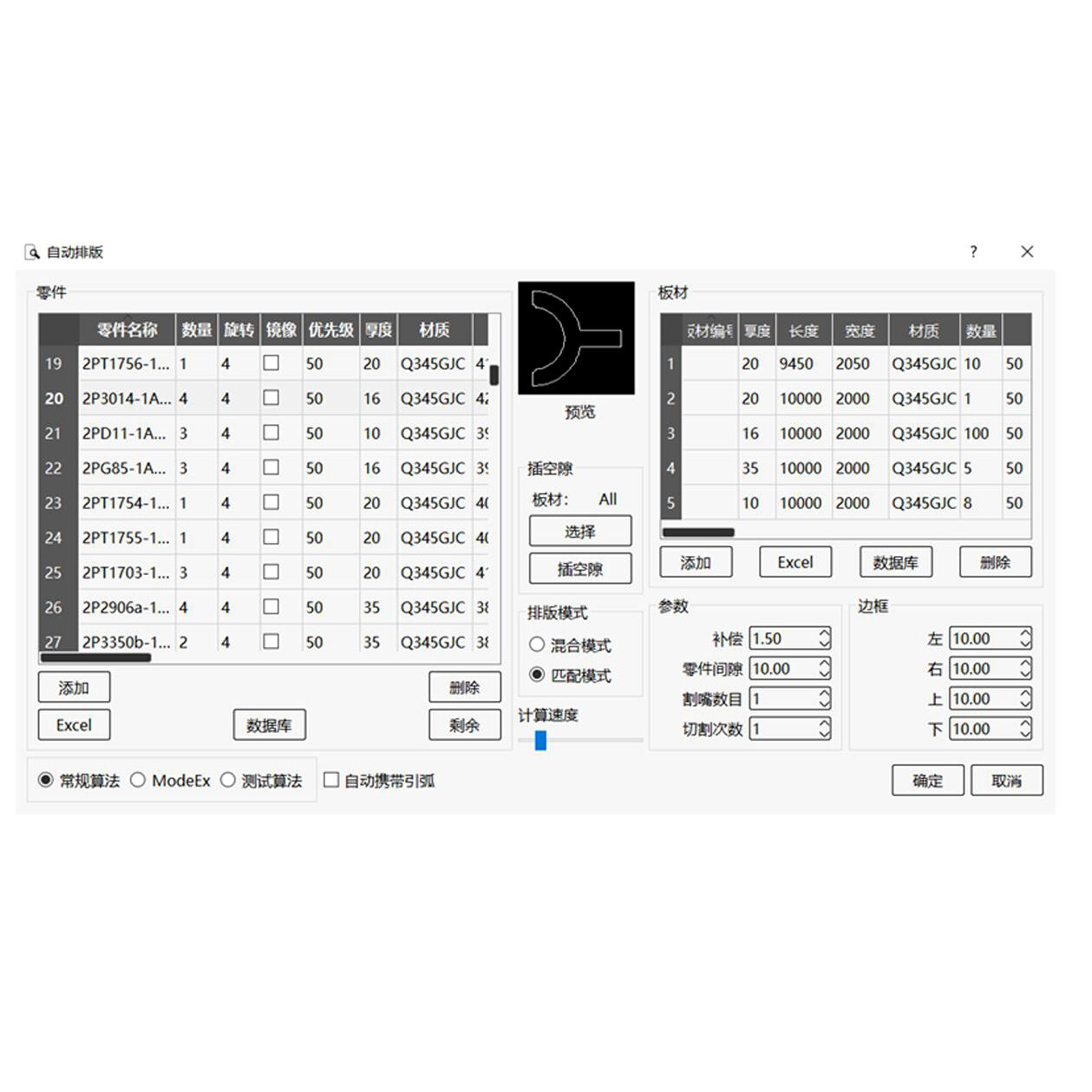

Fully Automatic Nesting Based on preset parameters, the software can automatically match the parts and materials according to thickness and material, and perform automatic nesting. |

Type

|

HiNest Compound Nesting The SinOCAM function of HiNest supports compound cutting nesting, which can be customized and developed for drilling, tapping, and milling functions according to the user's machine model. It also supports plasma/laser compound cutting nesting. |

|

|

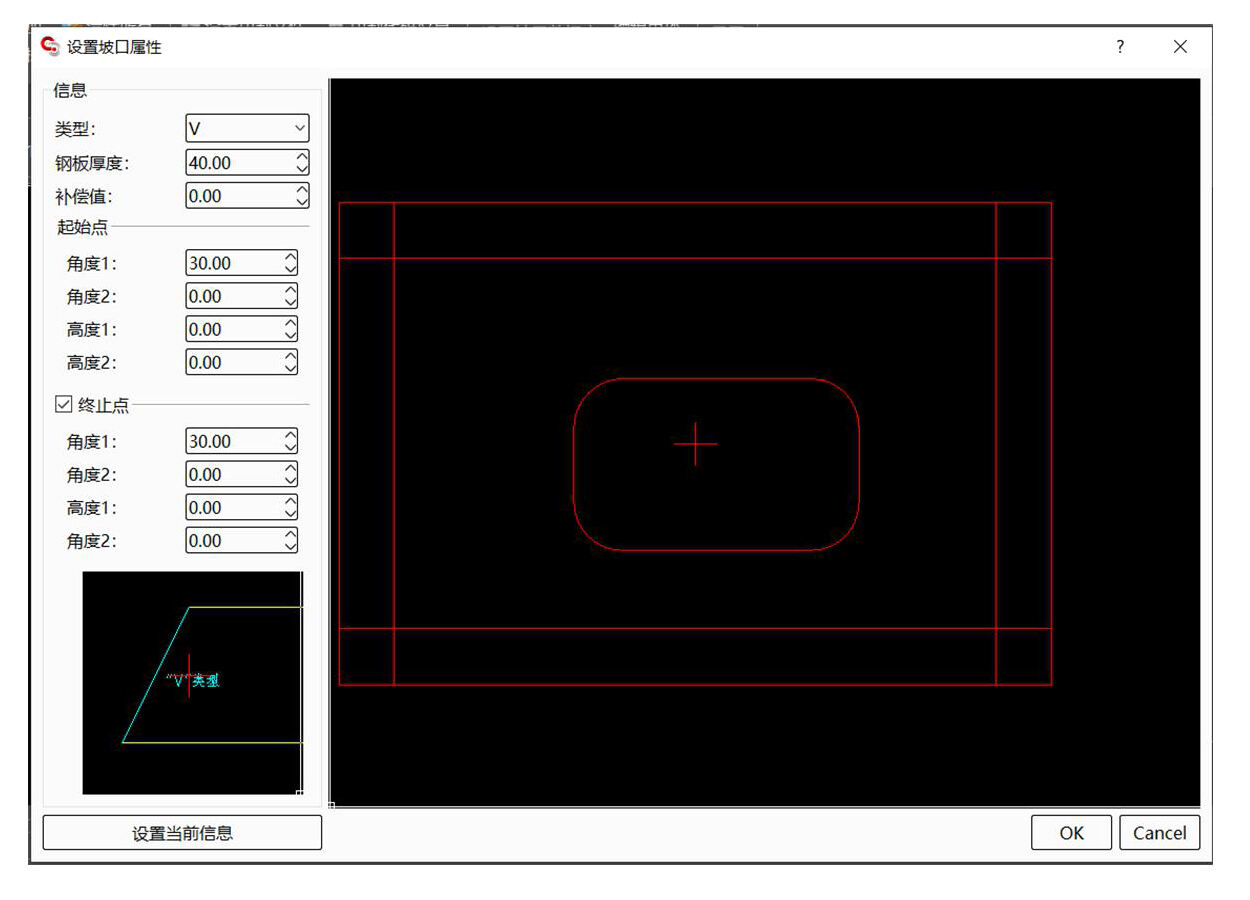

HiNest Bevel Nesting Bevel cutting supports V, Y, X, K and other bevel types, with simple and easy-to-learn visual parameter settings. It supports different cutting equipment, and the complete process setting helps operators master bevel nesting quickly. |

|

|

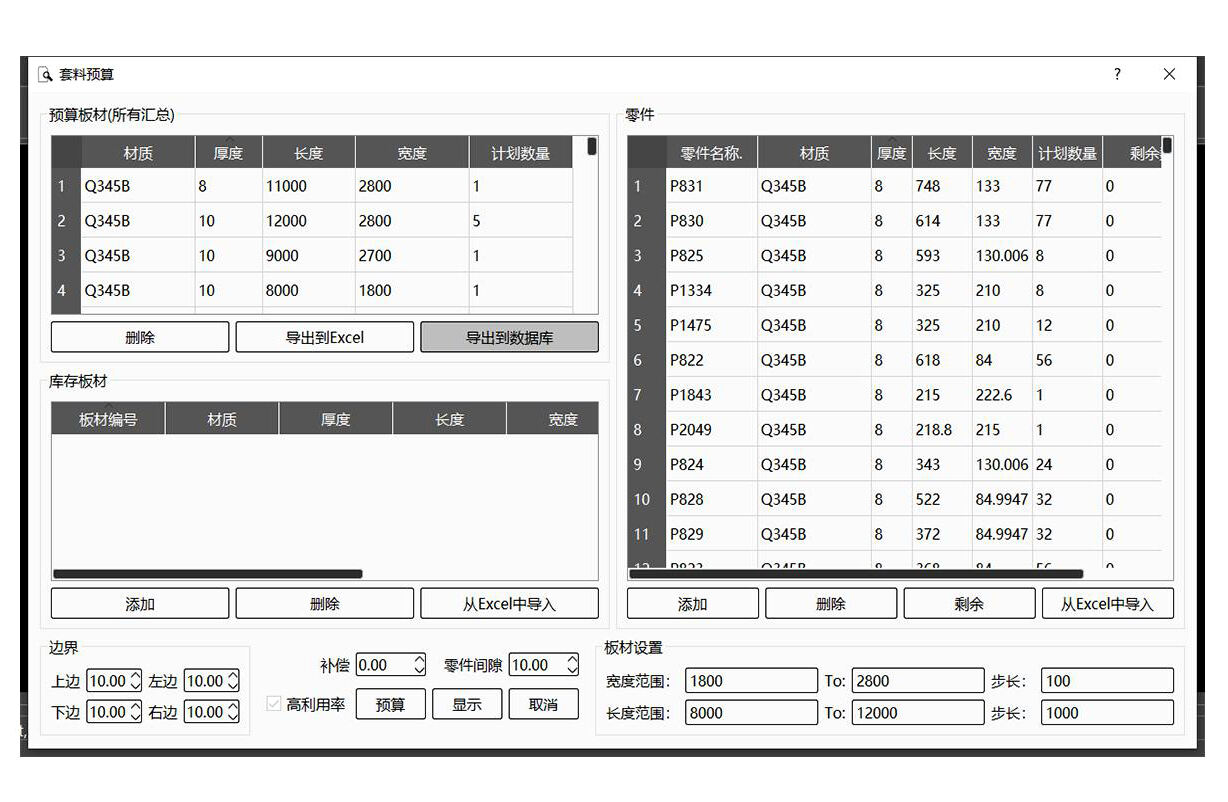

HiNest Processing Budget The pre-nesting function allows users to understand in advance the required plate quantity, production time, consumable costs, and other information needed for production, helping users develop accurate procurement plans. |

|

EN

EN

AR

AR CS

CS NL

NL FR

FR DE

DE IT

IT JA

JA KO

KO PL

PL PT

PT RU

RU ES

ES UK

UK TH

TH TR

TR