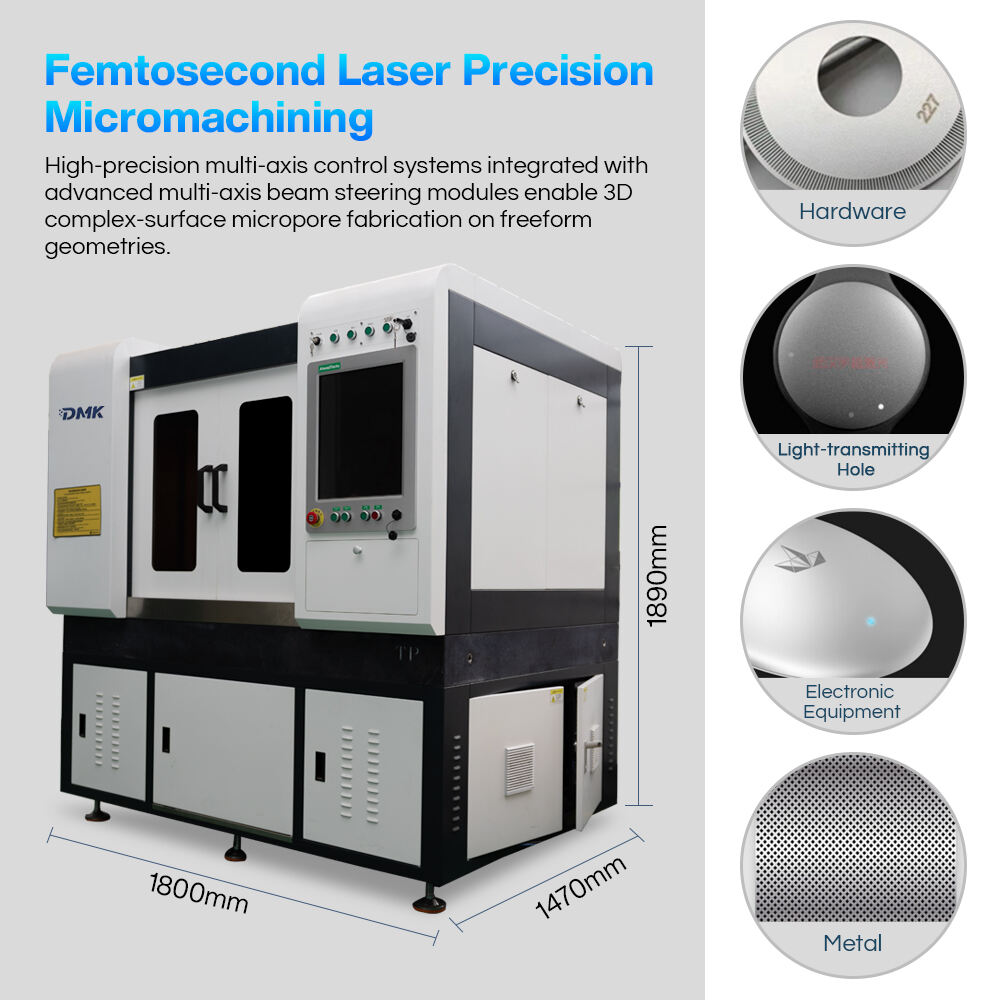

High-Precision Laser Micro-Hole Drilling Machine - 0.02mm Minimum Hole Diameter + ±0.01mm Positioning Accuracy + Linear Motor Drive - Special for 3C/Medical Devices/Military/Aerospace Micro-Hole Processing

Product Description

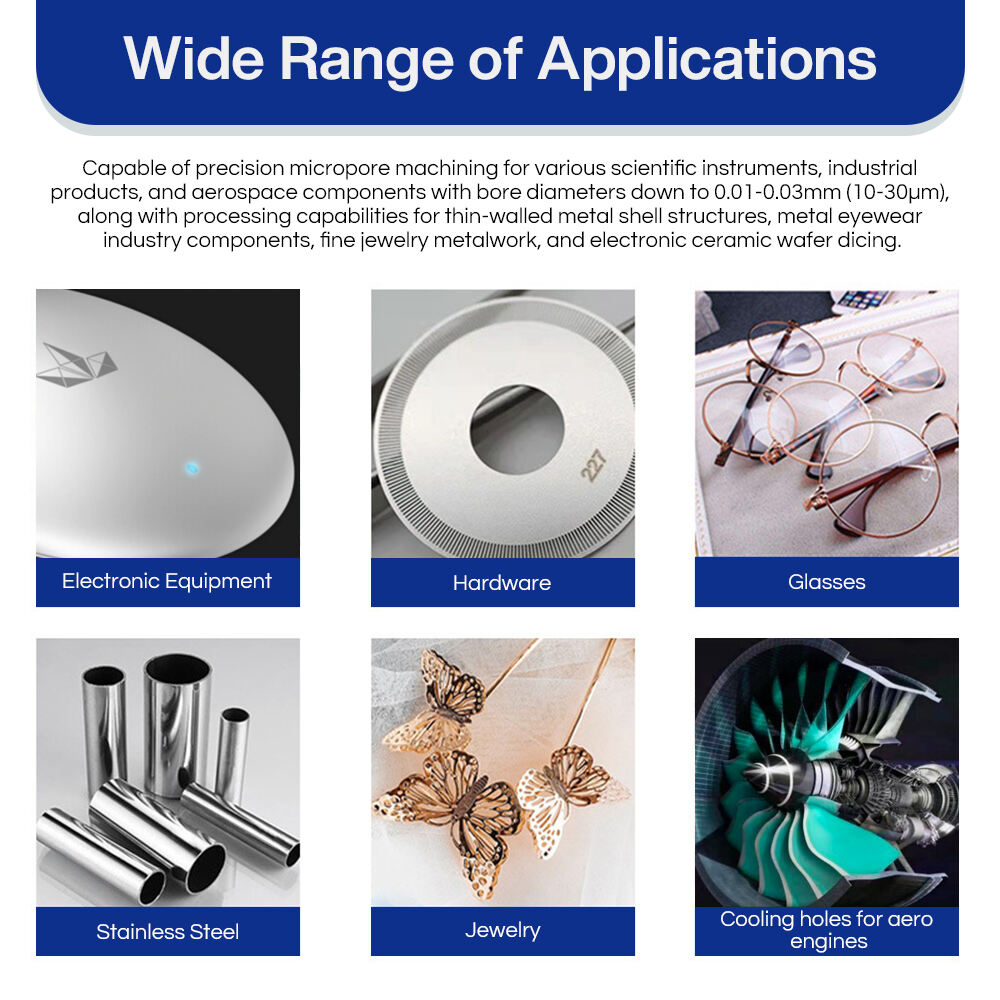

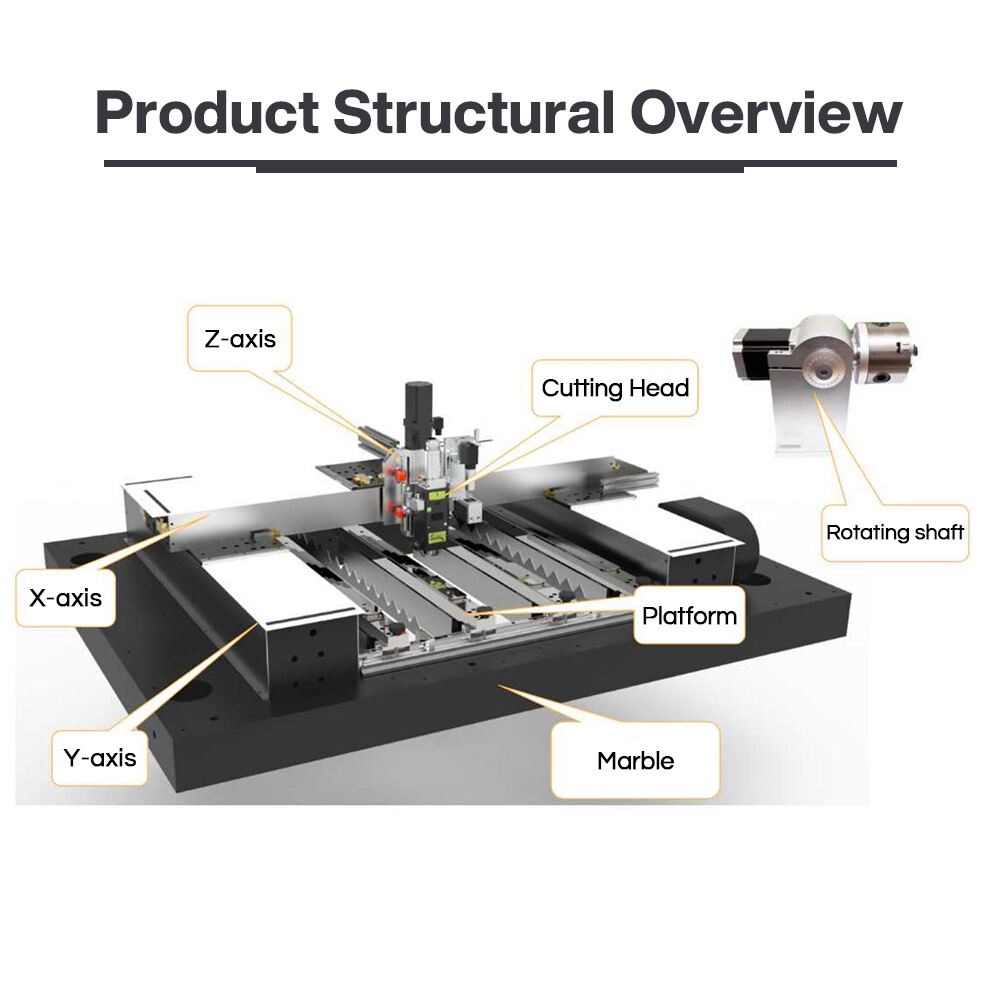

The equipment focuses on high-speed and high-precision cutting and micro-hole drilling of metal materials, including stainless steel, carbon steel, tungsten steel, aluminum alloy, titanium alloy, copper, etc. The minimum hole diameter can reach 0.02-0.03mm, reaching the advanced domestic level. It adopts a marble precision platform and gantry integrated closed structure, combined with imported linear motor, high-precision guide rail and 0.5um high-precision grating ruler full closed-loop feedback system, with positioning accuracy of ±0.01mm and repeat positioning accuracy of ±5um, ensuring processing accuracy and stability.

The non-contact processing method has small heat impact, minimal local workpiece deformation and no mechanical deformation, with narrow kerf and smooth burr-free cutting surface. Equipped with professional automatic programming software, 17-inch color LCD touch screen and multiple interfaces, it enables convenient file transmission and supports manual or automatic nesting. Widely used in processing scenarios such as light-transmitting holes of 3C wearable devices, micro-holes of atomizing sheets, metal filters, cooling holes of aero-engines, micro-holes of military products, it is an efficient solution in the field of precision manufacturing.

Product Parameters

| Parameter Category | Specific Parameters |

|---|---|

| Core Laser Parameters | - Laser Wavelength: 1060-1080nm - Laser Power: 150W - Laser Frequency: 1-5000HZ (Adjustable) |

| Processing Accuracy and Range Parameters | - Effective Cutting Area: 600×600mm - Positioning Accuracy: ±0.01mm - X/Y Axis Repeat Positioning Accuracy: ±5um - Drilling Accuracy: ±0.01mm - Minimum Hole Diameter (Material Thickness Dependent): ≥0.02-0.03mm - Processing Material Thickness: 0.1-1mm |

| Motion and Speed Parameters | - Transmission Method: Imported Linear Motor + 0.5um Grating Ruler - Processing Speed: 0-500mm/s - Maximum Moving Speed: 60m/min |

| Shape and Energy Consumption Parameters | - Overall Machine Power (Excluding Fan): ≦5KW - Total Machine Weight: Approximately 1600KG - External Dimensions: 1800×1470×1890mm (Subject to Actual Product) |

| Software and Interface Parameters | - Compatible File Formats: DXF or DWG - Operation Interface: 17-inch Color LCD Touch Screen - Interfaces: USB Interface, Ethernet Interface |

Other Details

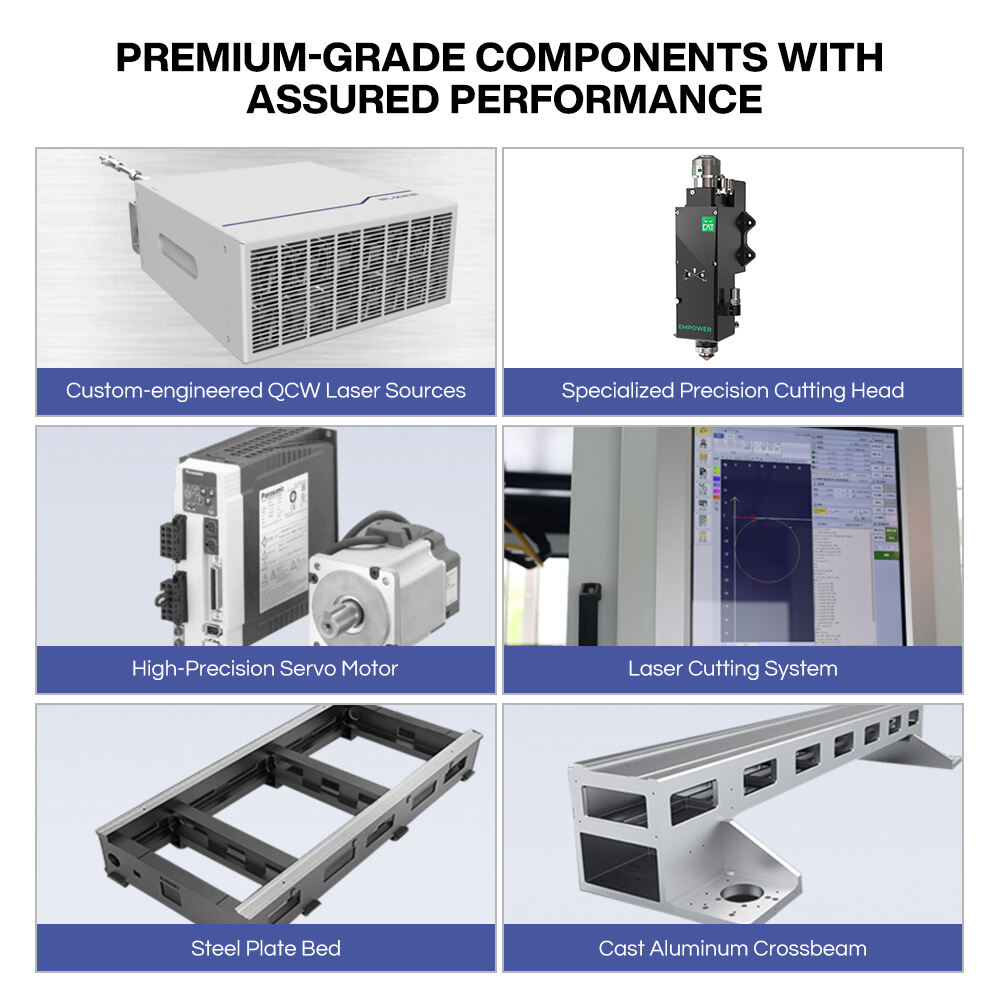

1、Equipment Configuration and Features

- Core Configuration: QCW customized fiber laser, Switzerland Raytools special precision cutting head, US AheadTechs bus-type closed-loop control system, Switzerland RT precision linear motor + marble table, Japan THK precision linear guide rail, Spain 0.5um grating ruler, France Schneider electrical components, etc.

- Core Features: Capacitive sensing cutting head that automatically adjusts cutting height according to material undulation; non-contact processing with small heat impact and no mechanical deformation; professional automatic programming software supporting nesting; strong machine rigidity, good shock resistance and stable high-speed operation.

2、Operating Costs and Environmental Requirements

| Operating Costs | Environmental Requirements |

|---|---|

| - Electricity Cost: Approximately 4.2 yuan/hour (set factor 60%) - Auxiliary Gas Cost: Liquid oxygen 9 yuan/hour, liquid nitrogen 26.7 yuan/hour, air 5 yuan/hour - Consumable Cost: Approximately 0.42 yuan/hour (protective lens, cutting nozzle, ceramic body) | - Power Supply Requirement: AC220V, 50Hz, recommended 30KVA regulated power supply, voltage stability ±5% - Room Temperature: 10℃~30℃ (air conditioning recommended to control temperature difference ±2℃) - Air Humidity: ≤75% - Auxiliary Gas Purity: Oxygen ≥99.95%, Nitrogen ≥99.99% |

3、Operation and After-sales Service

- Operation Process: Import processing files (DXF/DWG format) → Nesting → Set processing parameters (frequency, speed, hole diameter, etc.) → Start automatic processing → Check micro-hole quality after completion.

- After-sales Service: 1-year free warranty for the whole machine, lifelong maintenance; 24-hour customer service response; free 3-5 days technical training until operators can use it normally; free software and hardware upgrades after warranty period.

Sample Display

EN

EN

AR

AR CS

CS NL

NL FR

FR DE

DE IT

IT JA

JA KO

KO PL

PL PT

PT RU

RU ES

ES UK

UK TH

TH TR

TR