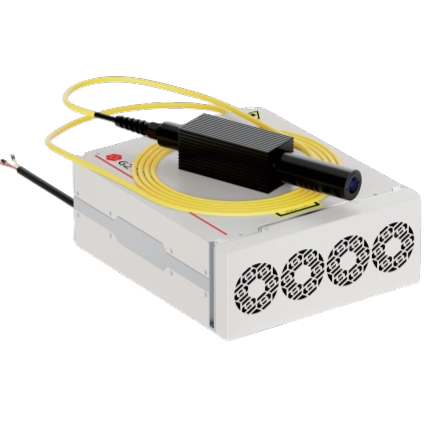

GZTECH GMF Series 30W-100W MOPA Pulsed Fiber Laser (Models YFPN-30/100-GMF)

Product Brief

This is GZTECH’s MOPA pulsed fiber laser specialized for the PCB industry, covering 30W-100W power range. It features ultra-narrow pulse width and high beam quality, making it ideal for fine scenarios like electronic component marking and PCB micromachining. It operates stably with fast response.

Product Features

- PCB Industry Specialization: Customized MOPA architecture design, adapting to fine processing needs such as PCB marking and micro-drilling.

- Ultra-Narrow Pulse Width Output: On/off light response time <2μs, and pulse width up to 2-500ns, ensuring micromachining precision.

- High Beam Quality: Beam quality M² <1.8 ensures excellent spot focus, suitable for fine marking of electronic components.

Compact & Lightweight: Weighs only 5-8kg with air-cooled design (no additional heat dissipation equipment needed), fitting small production lines.

- Stable & Reliable: Output power fluctuation <5% ensures strong consistency in long-term operation, suitable for batch electronic processing scenarios.

Product Parameter Table

| Category | YFPN-30-GMF | YFPN-100-GMF |

|---|---|---|

| Optical Properties | ||

| Wavelength | 1060-1080 nm | 1060-1080 nm |

| Average Power | 30 W | 100 W |

| Beam Quality M² | <1.5 | <1.8 |

| Max Single Pulse Energy | 1.2 mJ | 1.5 mJ |

| Repetition Rate Range | 1-3000 kHz | 1-3000 kHz |

| Pulse Width Range | 2-500 ns | 2-500 ns |

| Fiber Diameter | 7×1 mm | 7×1 mm |

| On/Off Response Time | <2 μs | <2 μs |

| Output Power Uncertainty | <5 % | <5 % |

| General Properties | ||

| Machine Dimensions | 315×220×95.5 mm | 315×220×100 mm |

| Weight | 5 kg | 8 kg |

| Supply Voltage | 24(DC) V | 48(DC) V |

| Max Power Consumption | 128 W | 384 W |

| Cooling Method | Air-cooled | Air-cooled |

Product Application Fields

- PCB board marking

- Water pipe marking printing

- Copper foil femtosecond drilling

- Electronic component marking

- Metal QR code marking

- Cable marking

- Copper foil femtosecond drilling

Product FAQ

-

What is the on/off light response time of this laser? Answer: The response time is <2μs, enabling high-speed and precise light output control to meet the fast-paced needs of PCB micromachining.

-

What is the key difference between the 30W and 100W models? Answer: The main differences are power and single pulse energy; the 100W model is more suitable for scenarios requiring higher energy, such as copper foil drilling.

-

Why is it described as PCB industry-specific? Answer: Its ultra-narrow pulse width and high beam quality precisely match fine processing needs like PCB board marking and copper foil drilling.

-

Is the equipment difficult to install? Answer: No—it weighs only 5-8kg, with an air-cooled design and universal interfaces, so it can be quickly integrated into PCB production line equipment.

- What is the adjustable pulse width range? Answer: The pulse width can be adjusted between 2-500ns, flexibly matching marking/processing processes for different electronic materials.

EN

EN

AR

AR CS

CS NL

NL FR

FR DE

DE IT

IT JA

JA KO

KO PL

PL PT

PT RU

RU ES

ES UK

UK TH

TH TR

TR