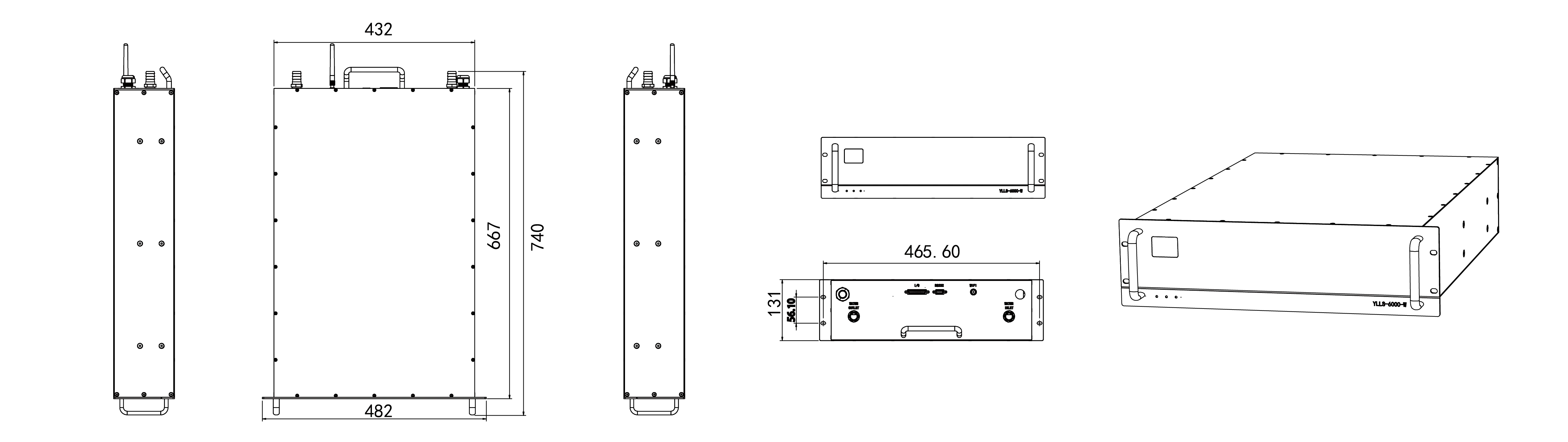

GW YLLS-6000-W High-Power Fiber Laser For Cladding Machine

Product Description

Experience next-generation laser processing with the YLLS-6000-W 6000W Fiber Laser — a compact, energy-efficient, and high-performance solution designed for heavy-duty industrial use. Its advanced single-module architecture and enhanced beam control make it a powerful tool for high-speed cutting and deep penetration welding.

This model is especially optimized for laser cladding, offering consistent energy delivery and precise control for demanding surface treatment jobs. Whether restoring parts or applying wear-resistant coatings, this laser delivers maximum efficiency and reliability.

Top Benefits

|

|

|

|

Technical Specifications

| Optical Specifications | |

| Output Power | 6000W |

| Operating Mode | Continuous / Pulse Output |

| Power Adjustment Range | 1–100% |

| Laser Wavelength | 1080 ± 10 nm |

| Beam Quality (BPP) | ≤2 |

| Power Stability | <5% (at 25 ± 1°C) |

| Max Modulation Frequency | 10 kHz |

| Response Time | <50 μs |

| Fiber Delivery System | |

| Interface Type | QBH |

| Core Diameter | 50 μm (standard; customizable) |

| Fiber Length | 15 ± 0.5 m (custom options available) |

| Cooling Specifications | |

| Cooling Method | Water Cooling |

| Minimum Cooling Capacity | 15 kW |

| Minimum Flow Rate | 65 L/min |

| Electrical & Environmental | |

| Operating Temperature | 5–45°C |

| Input Voltage | 380VAC / 50Hz |

| Power Consumption | <16 kW |

| Dimensions (L×W×H) | 432 × 667 × 131 mm |

| Weight | <60 kg |

Applications

Laser Cladding : Wear-resistant coatings, precision restoration of industrial components

Laser Cutting: Carbon steel, stainless steel, aluminum alloys

Laser Welding & Brazing: Clean seams with deep penetration

Surface Treatment: Heat treatment, coating, and corrosion-resistant layer building

Industry Use: Automotive, Aerospace, Medical Devices, Heavy Equipment, Precision Manufacturing

EN

EN

AR

AR CS

CS NL

NL FR

FR DE

DE IT

IT JA

JA KO

KO PL

PL PT

PT RU

RU ES

ES UK

UK TH

TH TR

TR