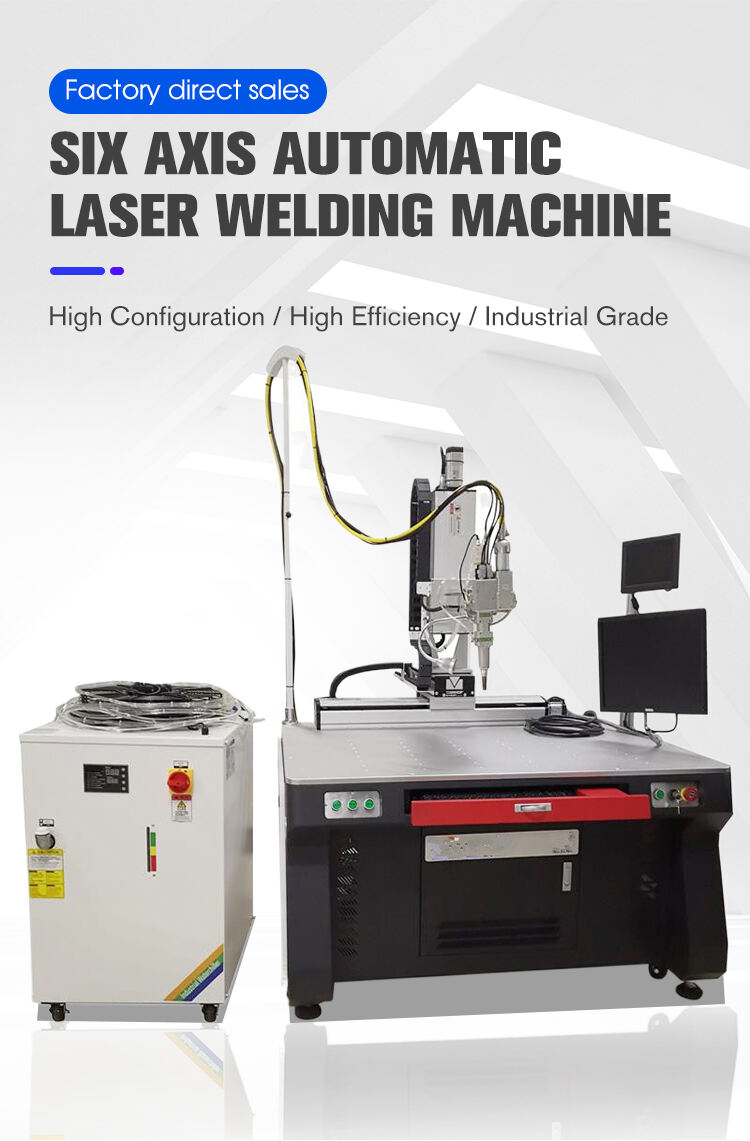

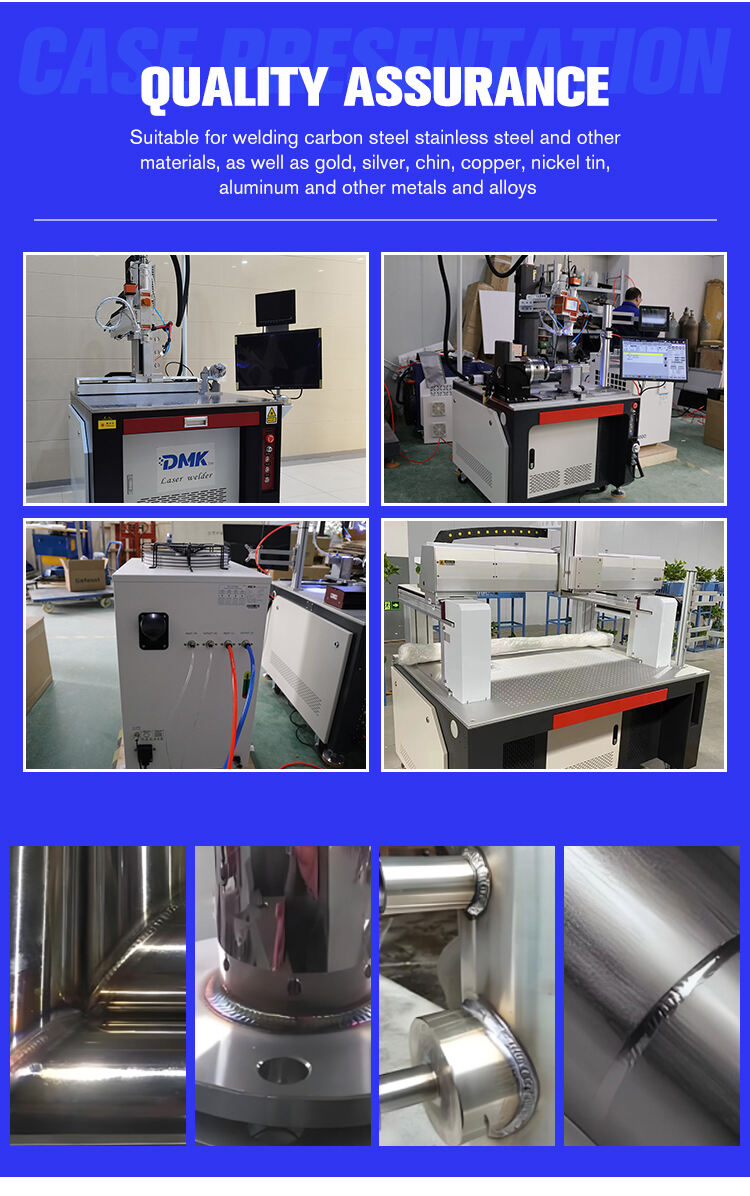

Galvanometer Precision Laser Welding Machine

Products Overview

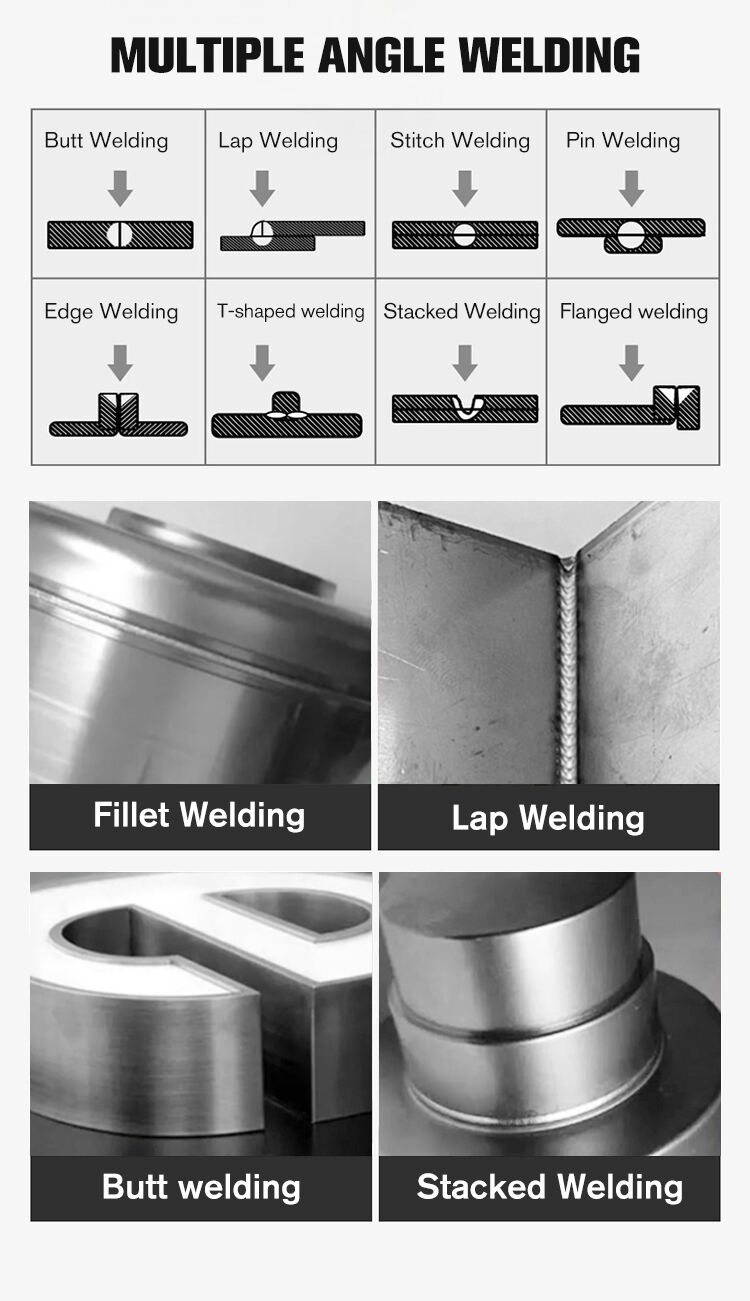

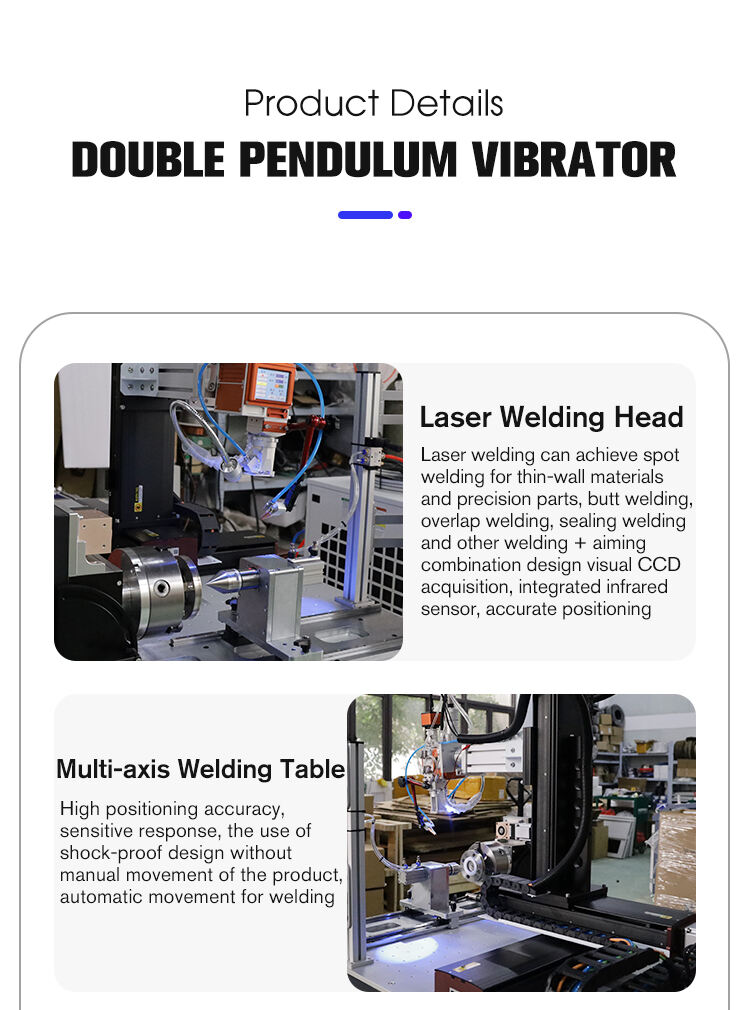

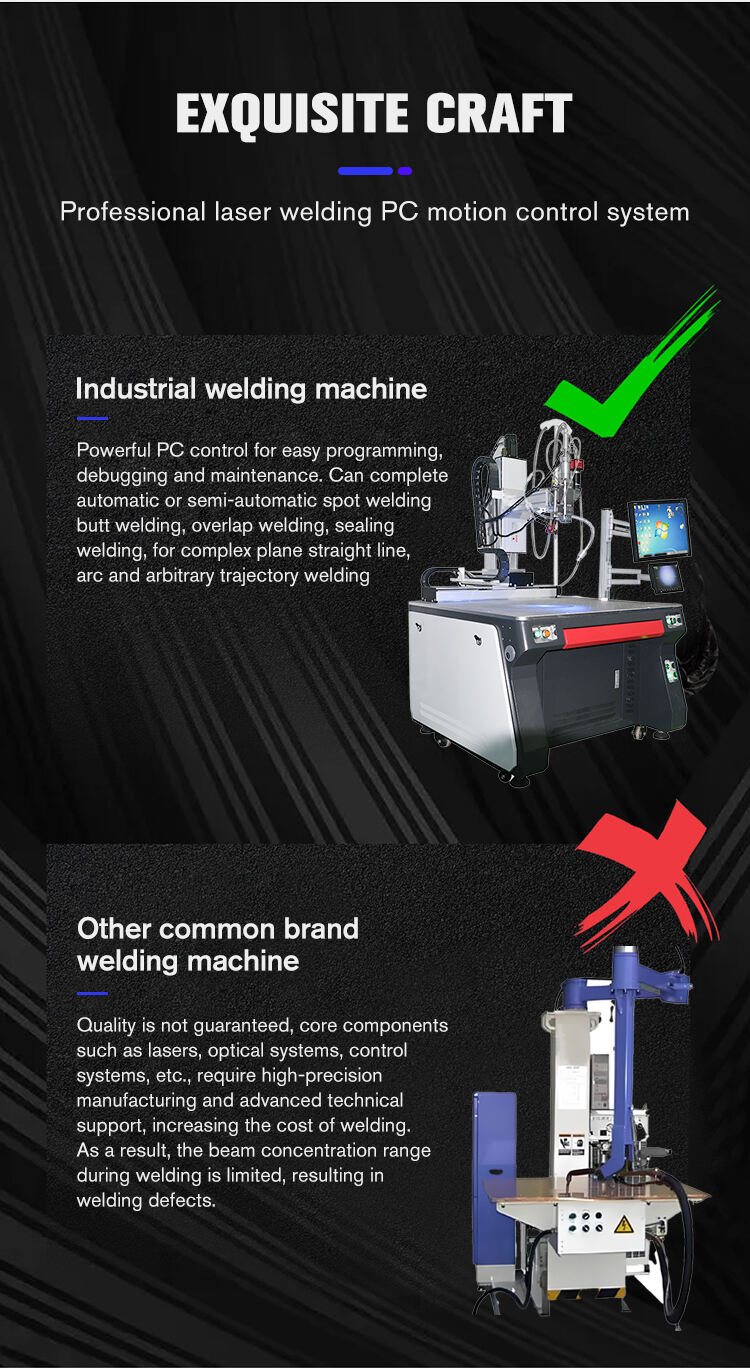

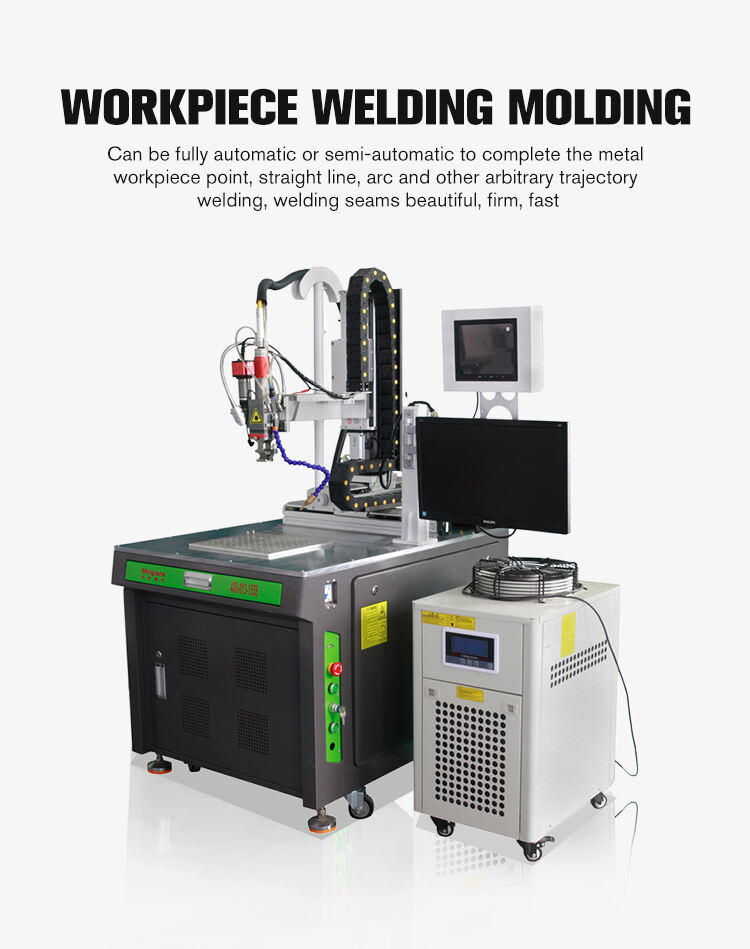

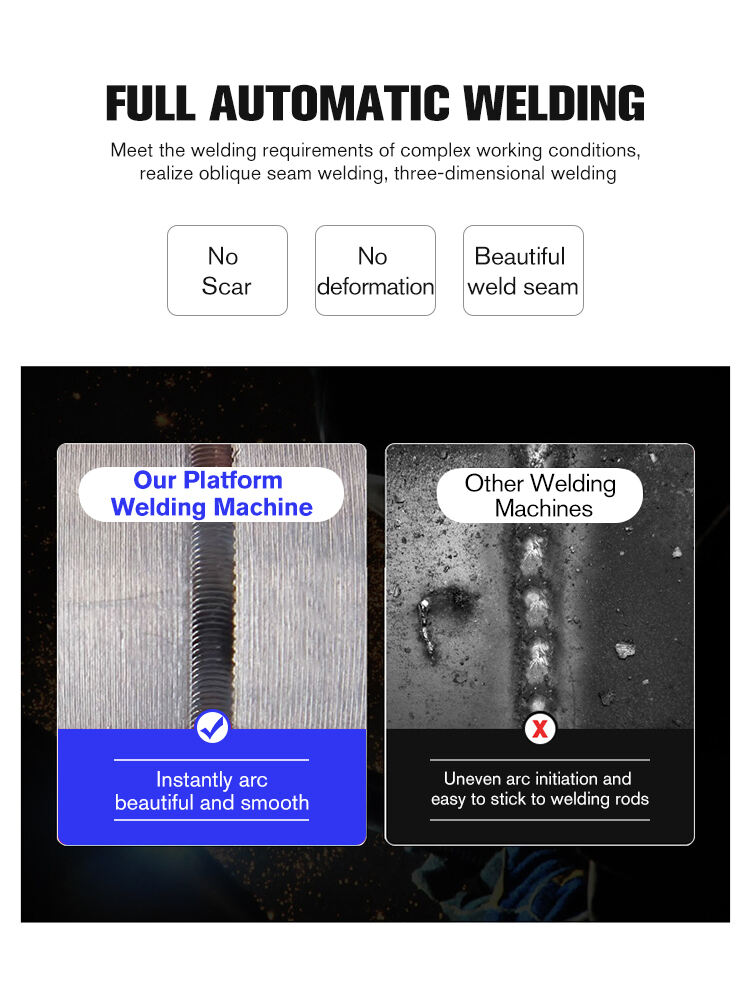

The laser of the galvanometer laser welding machine realizes the rapid movement of the laser point through the vibration of the galvanometer, so it can realize high-speed and high-precision guided spot welding and continuous welding of arbitrary graphics on the welding plane within the welding range, so it is better than the traditional The advanced automatic welding machine moves the workpiece through the stepping servo motor for welding, and the welding speed is greatly improved.

Products Parameters

This type of galvanometer laser welding machine uses fiber laser as the light source. During single-point welding, due to the greatly reduced empty positioning time, the production efficiency is 4-10 times higher than that of ordinary laser spot welding.

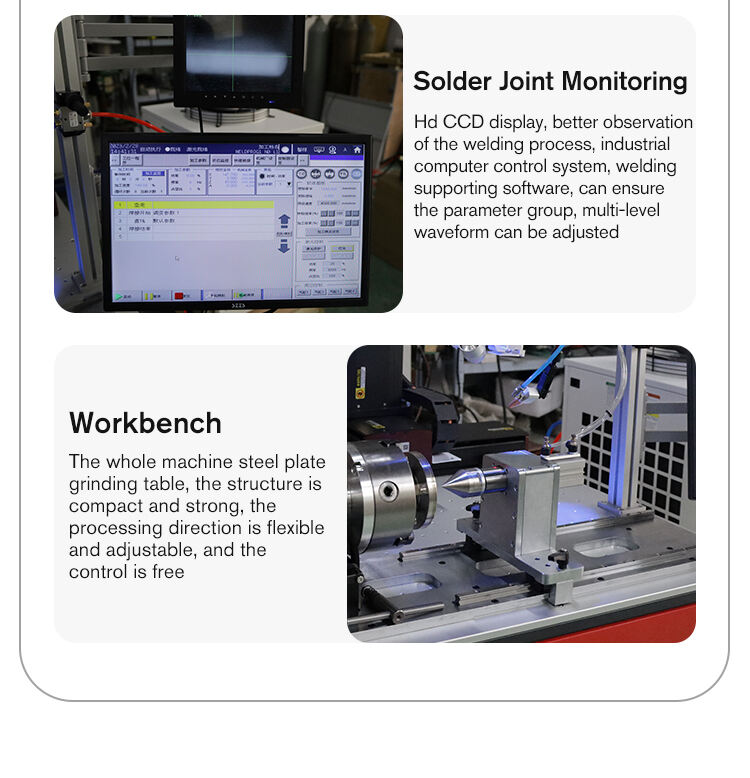

The galvanometer scanning laser welding machine is composed of a fiber laser, an optical scanning system, a system, an industrial computer system, a refrigeration system, a CCD, and an operating cabinet.

The galvanometer scanning laser welding machine provides a dedicated laser welding software based on the windows platform.

Welding points or graphics can be directly input and edited in its special software, or edited by other software such as Auto CAD, Corel DRAW, etc., and then imported and processed by its special software.

This machine has stable quality, convenient operation and simple maintenance.

| Maximum laser output power | Average power 150W Peak power 1500W |

| Laser wavelength | 1070nm |

| Laser control | continuous/pulse |

| Welding interface | QBH |

| Spot size | 0.1-2mm adjustable |

| Fiber length | 5 meters |

| Positioning | red light guide |

| Welding range | 110*110mm |

| Control system | Ezcad |

| Refrigeration | Air-cooled |

| Host power consumption | ≤5KW |

| Power requirements | 220V, 50/60Hz, 30A |

Products Application

Applied to offline/online welding of mass production enterprises in electronics, communication, hardware and other industries, including various types of batteries, mobile phone shields, metal mobile phone casings, metal capacitor casings, hard disks in computers, micro-motors, sensors, metal shielding nets, shavings High-efficiency laser spot or seal welding of blades and other types of electronic products.

EN

EN

AR

AR CS

CS NL

NL FR

FR DE

DE IT

IT JA

JA KO

KO PL

PL PT

PT RU

RU ES

ES UK

UK TH

TH TR

TR