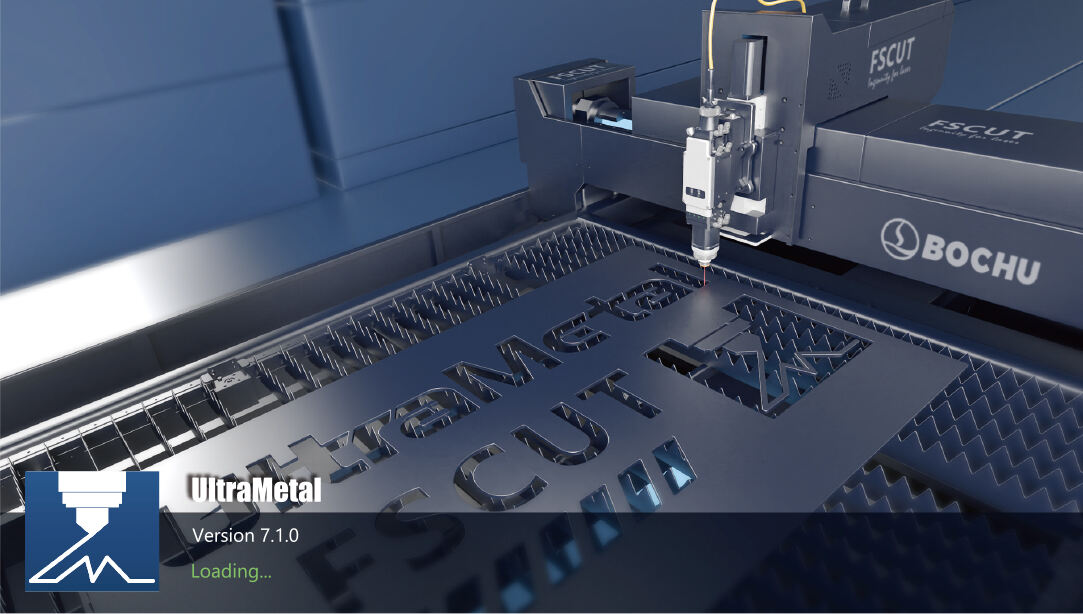

FSCUT7000E Precision Metal Laser Processing System

Product Introduction

The FSCUT7000E is built for manufacturers who need maximum precision and efficiency in metal laser processing. It combines advanced CNC control, capacitive height adjustment, and high-speed motion algorithms to deliver consistent, high-quality results — even in demanding production environments.

Model & Components:

FSCUT7000E Main System

Main Station Card: BMC228B

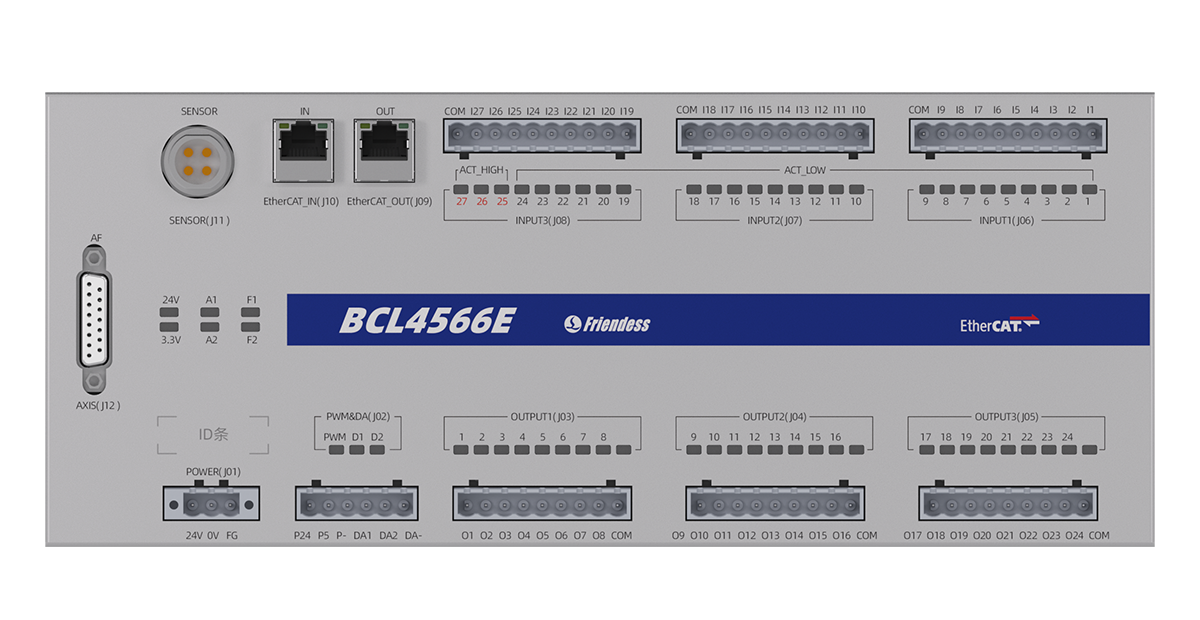

Capacitive Height Controller: BCL4566E

What It Delivers for Your Operation

Consistently Accurate Cutting

Integrated capacitive height control ensures stable Z-axis following, accurate edge detection, and reliable piercing. Features like leapfrog motion, progressive piercing, and real-time calibration reduce cycle times while maintaining cut quality.Optimized for Different Materials

Multi-stage piercing (up to 5 stages) and sensorless piercing let you fine-tune performance for a variety of metal types and thicknesses.Ultra-High Precision Motion

Trajectory command accuracy down to 0.1 μm, with actual machining precision of ±5 μm when paired with BCD Series drives — ideal for high-tolerance components.Gantry Dual-Drive Without the Hassle

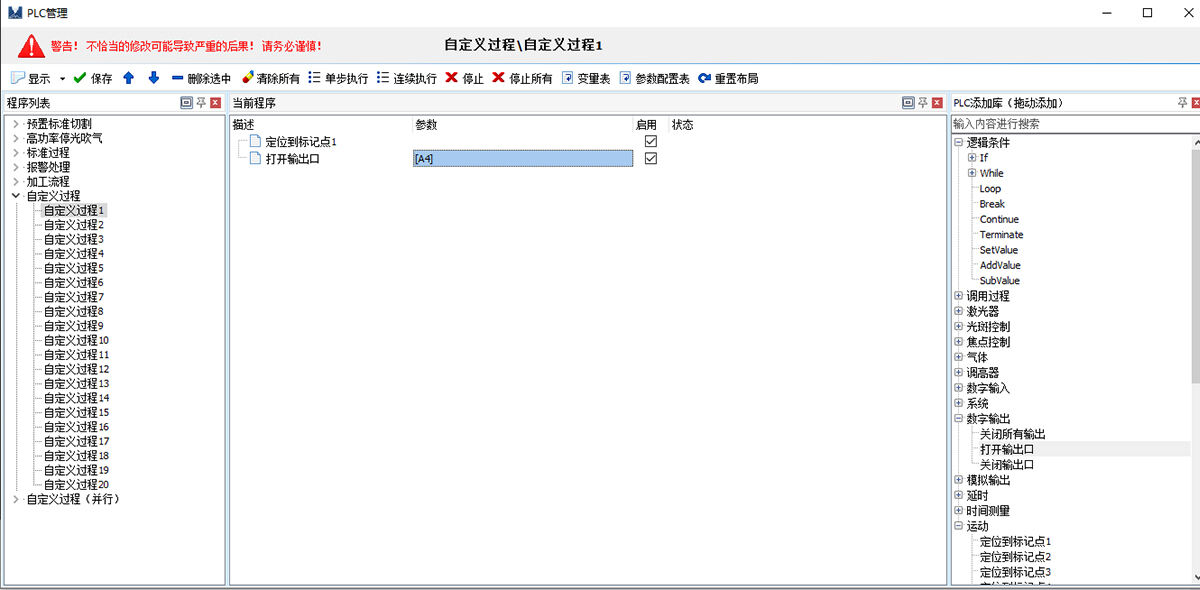

Core-level synchronization eliminates external wiring, increasing stability and reducing interference risks in gantry systems.All-in-One Software Workflow

UltraMetal software centralizes every step — from CAD file handling and process editing to automation control and diagnostics — into a single, efficient interface.

Applications

Precision metal fabrication shops

High-speed laser cutting production lines

Gantry-based precision machining systems

EN

EN

AR

AR CS

CS NL

NL FR

FR DE

DE IT

IT JA

JA KO

KO PL

PL PT

PT RU

RU ES

ES UK

UK TH

TH TR

TR