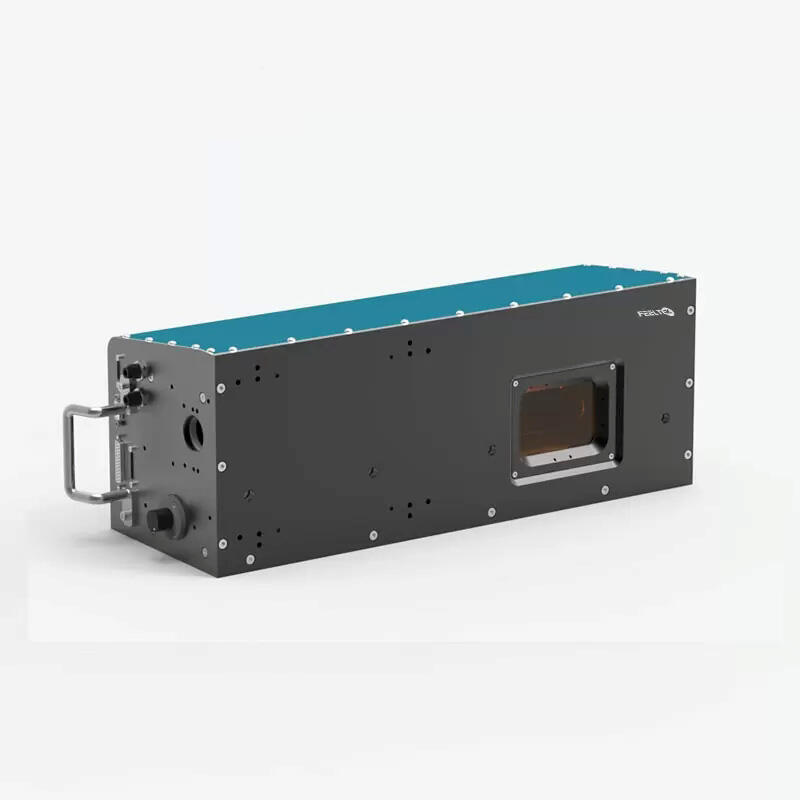

Feeltek FR40-CO₂ 3D Galvanometer

Product Description

The FEELTEK FR40-CO₂ 3D Front-Focus Dynamic System is a carbon dioxide laser equipment designed for high-end industrial precision processing. It is compatible with multi-wavelength light sources of 10640nm, 10200nm, and 9400nm, and offers two structural options: linear type (stable heat dissipation) and folded type (compact space-saving). It delivers outstanding performance in scenarios such as die cutting, high-precision processing, and large-area marking. Additionally, it supports optional water cooling and electric version switching, adapting to temperature drift-sensitive applications and automated production needs.

Product Features

1.Ultra-Fine Light Spot for Enhanced Processing Quality:Equipped with fully imported II-IV optical components, it features low light loss and excellent spot focusing performance. The minimum spot diameter reaches 0.12mm @ 150×150mm working range, resulting in minimal thermal damage and smooth edges during cutting-avoiding the issues of "rough cutting and heavy thermal damage" common with ordinary galvanometers. Within the ultra-large 1200×1200mm processing area, the spot uniformity remains stable with no marking deformation, meeting both precision processing and large-range processing requirements.

2.Flexible Structure & Easy Operation for Diverse Scenarios:

- Flexible Structure: The linear type adopts standardized mechanical components, offering strong heat dissipation and high stability, suitable for conventional industrial environments; the folded type is specifically designed for compact spaces, saving installation area and adapting to scenarios with limited production line layout.

- Easy Operation: An optional electric version allows control of working area and focal length switching via software, eliminating the need for manual adjustment and lowering the operation threshold.

- Optional Water Cooling: Supports optional water cooling (cooling medium: distilled water + anti-corrosion additive; temperature: 22-28℃; pressure: 2-3bar; flow rate: 4-6L/min), enabling stable operation in precision processing scenarios with extremely high temperature drift requirements.

3.Dual Advantages of High Speed & Precision for Guaranteed Processing Efficiency:It boasts excellent scanning speed, with a maximum processing speed of 350 characters/second @ 400×400mm, enabling rapid batch processing in scenarios like large-area marking and scribing. Strict precision control is achieved: repeated marking precision of 8μrad, drift of ≤0.2mrad during 8-hour continuous operation, maximum gain drift of 100ppm/k, and position drift of 30μrad/k. With minimal processing errors, it adapts to high-precision scenarios such as laptop case drilling and keyboard film cutting.

4.Adjustable Wide Processing Area for Diverse Needs:Through three-axis precise control, the processing area can be flexibly switched from 150×150mm (fine processing) to 1200×1200×200mm (ultra-large-area processing). It covers different needs from "small-range precision micro-holes" to "large-range curved surface marking" without equipment replacement, reducing equipment investment costs and improving production line compatibility.

Technical Parameters

Parameter Category |

Parameter Name |

Details (Distinguished by Structure Type) |

Optical Parameters |

Galvanometer Aperture (mm) |

40 |

System Input Spot Diameter (mm) |

7.5, 9, 12.5 |

|

General Specifications |

Input Voltage (VDC) |

±24 |

Rated Current (A) |

Linear type: 12A; Folded type: 10A |

|

Protocol |

XY2-100 Protocol |

|

Weight (KG) |

Linear type: 15; Folded type: 21.5 |

|

Dimensions (mm) |

Linear type: 538×200×242.5; Folded type: 547.5×200×184.5 |

|

Galvanometer Parameters |

Operating Deflection Angle (°) |

±11 |

Repeat Marking Precision (μrad) |

8 |

|

Maximum Gain Drift (ppm/k) |

100 |

|

Maximum Position Drift (μrad/k) |

30 |

|

8-Hour Continuous Operation Drift (mrad) |

≤0.2 |

|

Tracking Time (ms) |

≤0.68 |

|

Maximum Processing Speed (Characters/s) |

350 @ 400×400 |

|

Water-Cooling Conditions |

Cooling Medium |

Distilled water with anti-corrosion additive |

Temperature (℃) |

22-28 |

|

Recommended Pressure (bar) |

2-3 |

|

Recommended Flow Rate (L/min) |

4-6 |

Application

- Large-area marking

- Cutting

- Scribing

- Die cutting

EN

EN

AR

AR CS

CS NL

NL FR

FR DE

DE IT

IT JA

JA KO

KO PL

PL PT

PT RU

RU ES

ES UK

UK TH

TH TR

TR