Feeltek FR30-CO₂ 3D Galvanometer

Product Description

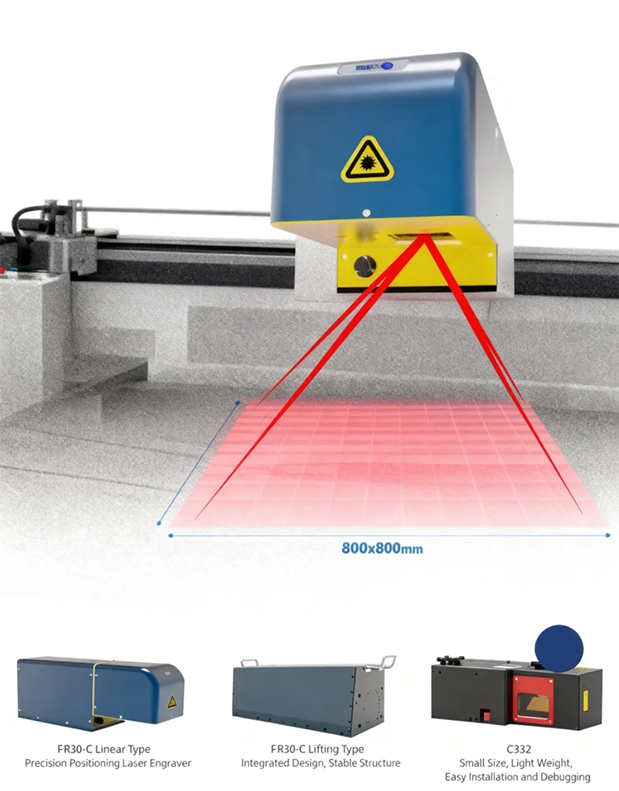

The FEELTEK FR30-C CO₂ 3D Front-Focus Dynamic System is a universal large-format processing equipment. It is compatible with multi-wavelength light sources of 10640nm, 10200nm, and 9400nm, and offers three structural models (linear type, foldable type, and C332) as well as three performance versions (Standard, Pro, and P2).

Equipped with a water-cooling design and modular expansion capability, the system has a minimum spot diameter of 0.11mm, a standard processing range covering 800×800mm, and a customized version that can extend up to 1600×1600mm. It delivers excellent performance in multiple scenarios such as 3D printing, cutting, and marking, and is especially suitable for industrial environments with high temperatures and limited space.

Product Features

- Multi-dimensional Adaptation to Meet Diverse Needs: Compatible with three wavelengths (10640nm, 10200nm, 9400nm) for processing different materials like leather, denim, and stone; available in three structures-linear type (stable with strong heat dissipation), foldable type (compact for space-constrained scenarios), and C332 model (optimized for small-range precision processing)-to cover different integration spaces and process requirements; three performance versions: Standard/Pro (ensuring basic high-precision processing) and P2 (with 5μrad repeat marking accuracy and ≤0.1mrad drift during 8-hour continuous operation, suitable for high-end industrial scenarios).

- Easy Operation & Integration for Efficiency Improvement: Equipped with a "focus adjustment knob" for easy switching of precise focal points across different processing formats without complex programming, lowering operation thresholds; optional off-axis CCD module supports positioning and marking of static or dynamic assembly line workpieces to meet automated production needs; adopts an integrated structure and XY2-100 universal protocol, facilitating integration with various industrial equipment and shortening production line construction cycles.

- Balance Between Precision Processing & Large Format: Minimum spot diameter of 0.11mm (for C332 model in 100×100×30mm working range) ensures clear processing edges, suitable for precision processes like leather hollowing and denim engraving; standard processing range of 800×800mm, with customized version extendable to 1600×1600mm and distortion-free marking across the entire format, solving issues of rough edge spots and limited marking range with ordinary galvanometers; supports SLS 3D printing technology, where dynamic axes can collaboratively adjust focus and spot as the number of processing layers increases, ensuring 3D printing precision and efficiency.

- Stability & Reliability for Harsh Environments: Optional water-cooling design (coolant: distilled water + anti-corrosion agent) controls operating temperature at 22-28℃, applicable to scenarios with strict temperature drift requirements (e.g., long-term continuous welding, high-temperature workshop processing); features mature multi-head galvanometer application solutions and dedicated calibration platforms, enabling synchronous processing of multiple devices to improve mass production efficiency while ensuring precision consistency.

Technical Parameters

Parameter Category |

Parameter Name |

Details (by Model/Version) |

Water Cooling |

Coolant |

Distilled water with anti-corrosion agent |

Temperature (℃) |

22-28 |

|

Recommended Pressure (bar) |

2-3 |

|

Recommended Flow Rate (L/min) |

4-6 |

|

General Specs |

Input Voltage (VDC) |

FR30-C Linear: ±24; FR30-C Foldable: ±15; FR30-C C332: ±24 |

Rated Current (A) |

10A |

|

Weight (KG) |

Linear: 15; Foldable: 13.5; C332: 21 |

|

Dimension (mm) |

Linear: 538×200×242.5; Foldable: 538×200×206; C332: 422×145×163 |

|

Optical Parameters |

Galvanometer Aperture (mm) |

All models: 30 |

System Input Spot Diameter (mm) |

FR30-C Linear & Foldable: 7.5, 9; FR30-C C332: 7.5, 9, 15 |

Application

- 3D Printing Field

- Cutting & Die-Cutting Field

- Marking & Scribing Field

- Surface Treatment & Cleaning Field

- Assembly Line & Flying Processing Field

EN

EN

AR

AR CS

CS NL

NL FR

FR DE

DE IT

IT JA

JA KO

KO PL

PL PT

PT RU

RU ES

ES UK

UK TH

TH TR

TR