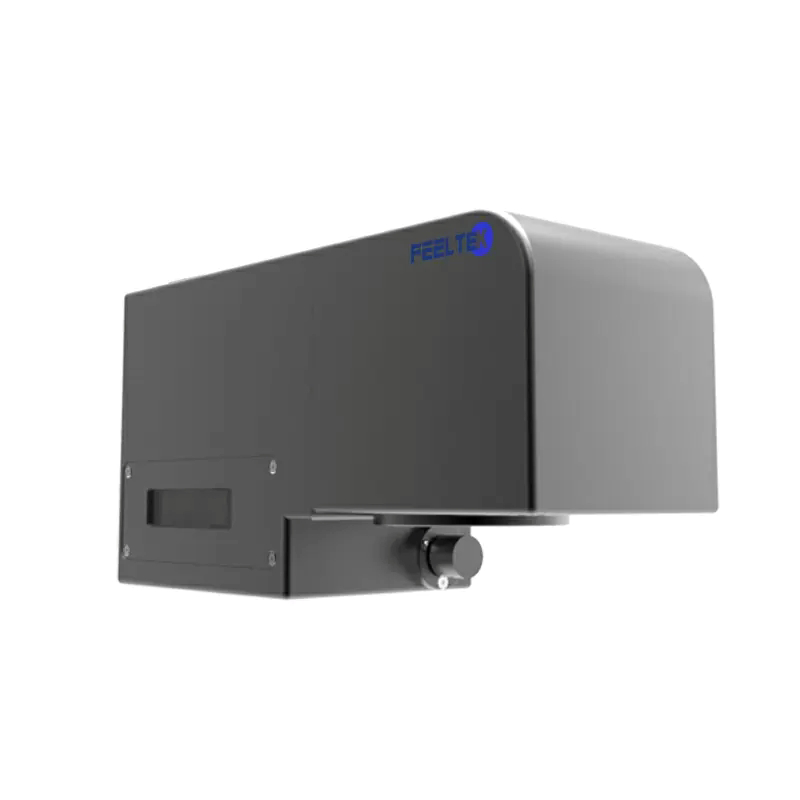

Feeltek FR10-UV Galvanometer 3D Front-Focus Dynamic System

It is compatible with 355nm light sources and enables ultra-large-size curved surface processing of 600×600×150mm. Adopting an integrated CNC structure with dust-proof and shielding design, it features easy focusing and precise laser spot control. Breaking through the limitations of traditional marking in terms of dimension and range, it is the first choice for entry-level industrial 3D dynamic focusing, and is widely used in scenarios such as large-format marking and curved surface etching.

Product Features

- Easy Integration: With an integrated CNC structure, coupled with dust-proof and shielding design, it is compact and small in size. It can be easily integrated into various industrial production equipment and scenarios, reducing integration difficulty and enhancing the flexibility of production layout.

- Convenient Focusing: Equipped with a "focusing knob", operators can easily switch precise focal points for different processing ranges without complex operations. This reduces focusing time, improves processing efficiency, and lowers the operation threshold.

- Ultra-Large Processing Range and Precise Laser Spot: Featuring a dual-drive Z-axis dynamic module design with a response frequency of ≥100Hz@±10°, it can achieve an ultra-large curved surface processing range of 600×600×150mm. Through three-axis dynamic focusing control, the laser spot remains uniform throughout the 3D processing range, and a spot diameter of 0.039mm can be maintained within the 600×600×150mm processing area, avoiding issues such as thick edge spots and marking deformation of ordinary galvanometers.

- Breaking Traditional Processing Limitations: Controlled by a dynamic focusing system, it breaks the limitations of traditional 2D galvanometer marking in dimension and range. It can perform distortion-free marking on objects with various complex shapes such as 3D curved surfaces, steps, conical surfaces, and inclined surfaces, solving problems of 2D galvanometer marking like incorrect focal length on different planes, edge defocusing and deformation, and incomplete marking.

Technical Parameters

Parameter Category |

Parameter Name |

Details |

Optical Parameters |

Galvanometer Aperture (mm) |

10 |

System Input Spot Diameter (mm) |

6.5 |

|

General Specifications |

Input Voltage (VDC) |

15 |

Rated Current (A) |

10A |

|

Version Option - Weight (KG) |

7 |

|

Working Deflection Angle (°) |

±11 |

|

Galvanometer Parameters |

Overall Dimension (mm) |

292×115×152.8 |

Repeat Marking Precision (μrad) |

8 |

|

Maximum Gain Drift (ppm/k) |

100 |

|

Maximum Position Drift (μrad/k) |

30 |

|

8-Hour Continuous Operation Drift (mrad) |

Standard Version: ≤0.2; Pro Version: ≤0.2; P2 Version: ≤0.1 |

|

Tracking Time (ms) |

Standard Version: ≤0.13; Pro Version: ≤0.13; P2 Version: ≤0.13 |

|

Maximum Processing Speed (Characters/s) |

600@100×100 |

Application

- Large-format marking

- Curved surface light-transmitting etching and marking

- PCB marking

EN

EN

AR

AR CS

CS NL

NL FR

FR DE

DE IT

IT JA

JA KO

KO PL

PL PT

PT RU

RU ES

ES UK

UK TH

TH TR

TR