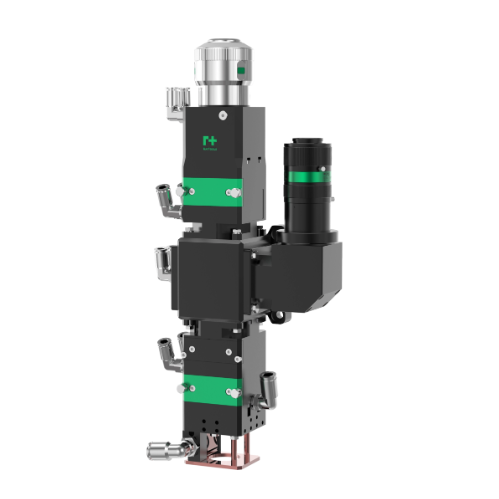

Empower BW Transmissive Laser Welding Heads BW03K BW06K

Product Description

The Empower BW series includes two models: BW03K (for lasers below 3000W) and BW06K (for lasers below 6000W), designed for low‑power multi‑source and medium‑to‑high‑power fiber laser welding applications, respectively.

- BW03K is compatible with fiber, semiconductor, and blue laser sources, ideal for thin‑sheet welding of both ferrous and non‑ferrous metals, delivering fast welding speeds and bright, clean seams.

- BW06K focuses on deep‑penetration welding of medium‑thick materials, producing high depth‑to‑width ratios in welds.

Both models feature efficient water cooling, versatile expansion modules (seam tracking/seeking), and high‑definition CCD real‑time monitoring, offering excellent cost‑performance and seamless integration into automated welding systems.

Product Features

1.Precise Power and Application Matching

- BW03K: 3000W class, compatible with 1064nm (fiber), 830–1030nm (semiconductor), and 450nm (blue) wavelengths; optimized for thin‑sheet welding of ferrous/non‑ferrous metals with fast speeds and bright, smooth seams.

- BW06K: 6000W class, designed for 1064nm fiber lasers; specializes in deep‑penetration welding of medium‑thick materials, solving the problems of low efficiency and poor bead formation in thick‑plate welding.

2.Stable and Durable for Long-Term Operation

Both models adopt efficient water‑cooled collimator + focusing lens mounts for long‑term stable performance and extended component lifespan. BW06K is additionally equipped with dual protective windows to prevent dust and spatter damage, further enhancing durability.

3.High Adaptability and Automation Compatibility

Support for optional seam tracking and position‑seeking modules enables easy integration into automated production lines. Both can be paired with HD CCD for real‑time seam monitoring, allowing timely process adjustments. Optimized gas flow designs (BW06K features coaxial/side‑axial protective nozzles plus an air knife) ensure excellent molten pool protection and spatter removal, guaranteeing welding quality.

4.High Cost-Performance

BW03K meets low‑power market demands for small‑to‑medium batch thin‑sheet processing. BW06K delivers outstanding value in the 6kW range, enabling high‑quality medium‑thick plate welding without high investment, balancing performance and cost.

Technical Parameters

Parameter Category |

Parameter Name |

BW03K Details |

BW06K Details |

Core Performance |

Power Rating |

3000W (for lasers ≤3000W) |

6000W (for fiber lasers ≤6000W) |

Aperture Diameter |

28mm |

35mm |

|

Optical Parameters |

Laser Wavelength |

1064nm (fiber), 830–1030nm (semiconductor), 450nm (blue) |

1064nm (fiber) |

Physical Parameters |

Weight |

~3.0kg |

~4.0kg |

Functional Options |

Expansion Modules |

Optional seam tracking/positioning |

Optional seam tracking/positioning |

Real-Time Monitoring |

HD CCD compatible |

HD CCD compatible |

|

Protective Design |

Lens Protection |

- |

Dual protective windows |

Gas Flow Design |

Molten Pool Protection |

Optimized airflow structure |

Coaxial/sideaxial nozzle + air knife |

Application

- Thin‑Sheet Processing (Mainly BW03K):Suitable for home appliance sheet metal (refrigerator door panels, washing machine drums), electronic components (metal enclosures, connectors), and other thin‑sheet welding tasks. Multi‑wavelength compatibility handles stainless steel, aluminum, copper, etc., producing bright, aesthetically pleasing seams that meet appearance and precision requirements.

- Medium‑Thick Material Welding (Mainly BW06K):Ideal for construction machinery (brackets, boxes), pressure vessels, pipelines, and other medium‑thick plates (5–20mm). Deep‑penetration welding delivers high strength and can replace traditional arc welding, improving efficiency and bead quality.

- Automated Production Lines (Both Models):Integrates into automotive parts (door frames, chassis components) and medical device (metal stents) production lines. With optional seam tracking/positioning and CCD monitoring, it enables precise batch welding, reduces manual intervention, and ensures consistency.

- General Metal Fabrication (Both Models):Covers hardware (stainless steel furniture, tooling parts) and general machinery (motor end caps, gearboxes). BW03K handles small thin‑sheet parts, while BW06K processes large thick‑plate components, offering flexible adaptation to various production scales and processes.

EN

EN

AR

AR CS

CS NL

NL FR

FR DE

DE IT

IT JA

JA KO

KO PL

PL PT

PT RU

RU ES

ES UK

UK TH

TH TR

TR