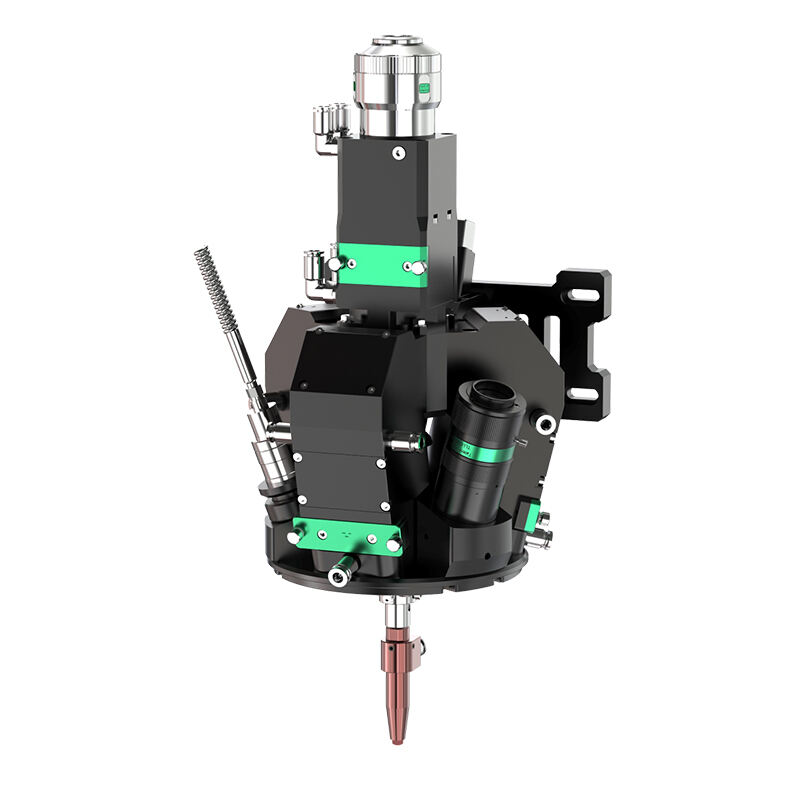

Empower BP06K Coaxial Wire-Feeding Laser Welding Head

Product Description

The Empower BP06K Coaxial Wire-Feeding Laser Welding Head is compatible with a 6000W power level, with a transmission wavelength of 900-1100nm and support for wire diameters ranging from 0.8mm to 1.6mm. Its core advantage lies in the "three-beam wire-enveloping design": the incident laser is shaped into three beams with uniform energy distribution, which are reflected, focused, and converged vertically in a conical shape to wrap the wire evenly for melting.

Compared with similar foreign products, it features a simpler optical solution and lower operating costs. The device also boasts excellent cladding quality and efficient cooling, making it widely applicable in laser cladding and precision processing scenarios.

Product Features

- High Cost-Effectiveness for Cost Reduction & Efficiency Improvement

The simplified yet reliable optical solution avoids high maintenance costs caused by complex structures. With a compact size and weight of only approximately 8.0kg, it is easy to integrate into various processing equipment while reducing operating and maintenance costs.

- Excellent Cladding Quality & Stable Process

Adopting the three-beam wire-enveloping solution, the wire/powder is output coaxially from the inner side without directional restrictions, resulting in minimal spatter during the melting process. The 360° annular air knife protection isolates smoke and spatter, preventing lens contamination and ensuring consistent processing accuracy.

- Efficient Cooling for Extended Service Life

Key lenses adopt a direct water-cooling design, which effectively reduces the impact of the thermal lens effect, prevents lens damage due to high temperatures, extends the service life of core components, and ensures stable long-term operation.

- Modular Expansion for Diverse Needs

It can be equipped with a CCD monitoring module and a closed-loop temperature control module to monitor the processing process and temperature changes in real time, facilitating timely adjustment of process parameters and enhancing the controllability of processing quality.

Technical Parameters

| Parameter Category | Parameter Name | Details |

|---|---|---|

| Core Performance Parameters | Power Level | 6000W |

| Transmission Wavelength | 900-1100nm | |

| Wire-Feeding Parameters | Compatible Wire Diameter | 0.8-1.6mm (regularly compatible with 0.8mm, 1.0mm, 1.2mm, 1.6mm) |

| Gas Parameters | Coaxial Shielding Gas Flow Rate | 0-20L/min |

| Air Knife Shielding Gas Flow Rate | 0-40L/min | |

| Physical Parameters | Weight | ~8.0kg |

| Optional Configurations | Expansion Modules | CCD monitoring module, closed-loop temperature control module |

Application

Laser Cladding Repair Field

Suitable for repairing wear and corrosion of mechanical parts (such as gears and shaft components). The three beams evenly wrap the wire, ensuring tight bonding of the cladding layer with minimal spatter, which can restore the size and performance of parts and reduce the cost of replacing new parts.

High-Hardness Coating Preparation Field

Used for preparing high-hardness coatings (such as wear-resistant and corrosion-resistant coatings) on the surface of metal workpieces, such as surface strengthening of molds and cutting tools. The modular temperature control and CCD monitoring enable precise control of coating thickness and quality, extending the service life of workpieces.

Precision Component Processing Field

For precision components in the aerospace and automotive industries (such as engine parts and transmission components), the non-directional coaxial wire-feeding design can adapt to the processing of complex structures, ensuring the processing accuracy and surface quality of key parts of the components.

General Industrial Additive Manufacturing Field

Applied in additive manufacturing of small metal components. The multi-specification wires (0.8-1.6mm) meet different forming needs, and efficient cooling and air knife protection ensure stable forming processes, reducing the rejection rate of additive manufacturing.

EN

EN

AR

AR CS

CS NL

NL FR

FR DE

DE IT

IT JA

JA KO

KO PL

PL PT

PT RU

RU ES

ES UK

UK TH

TH TR

TR