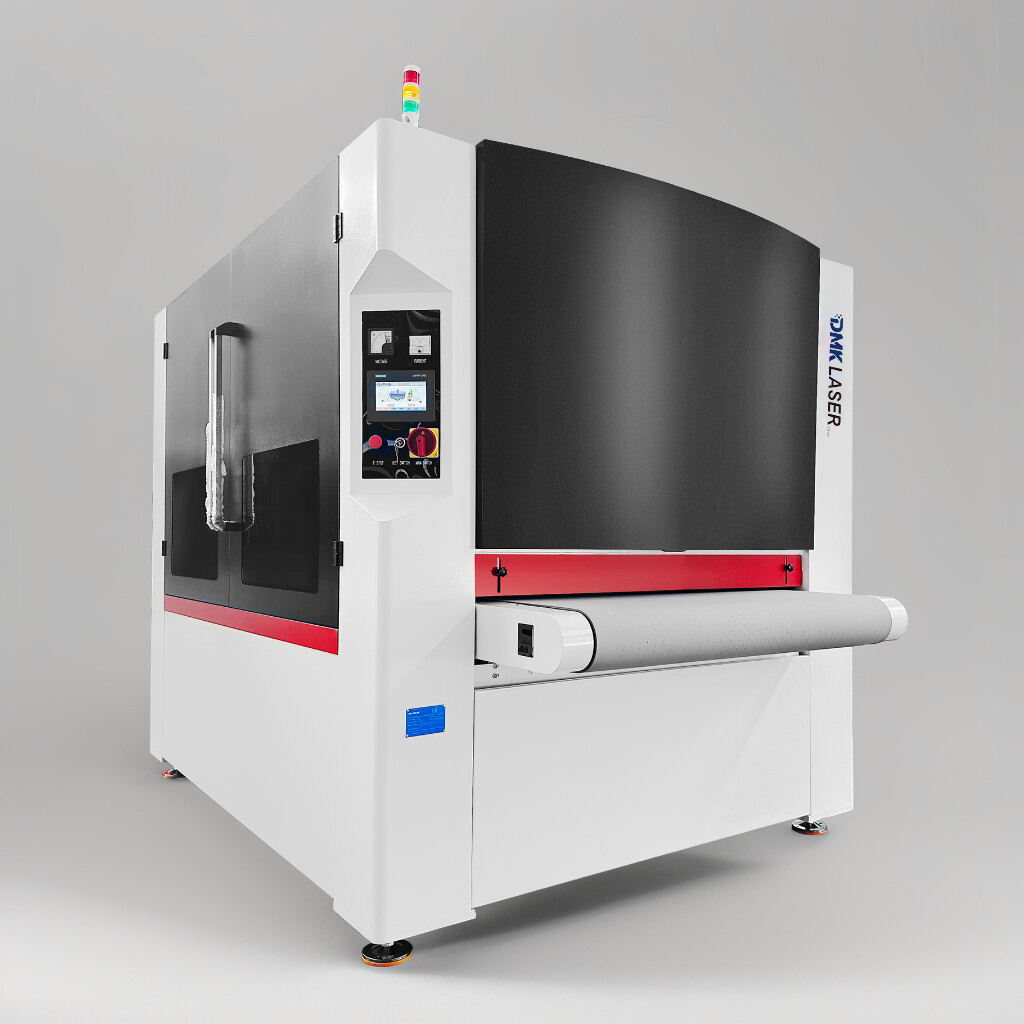

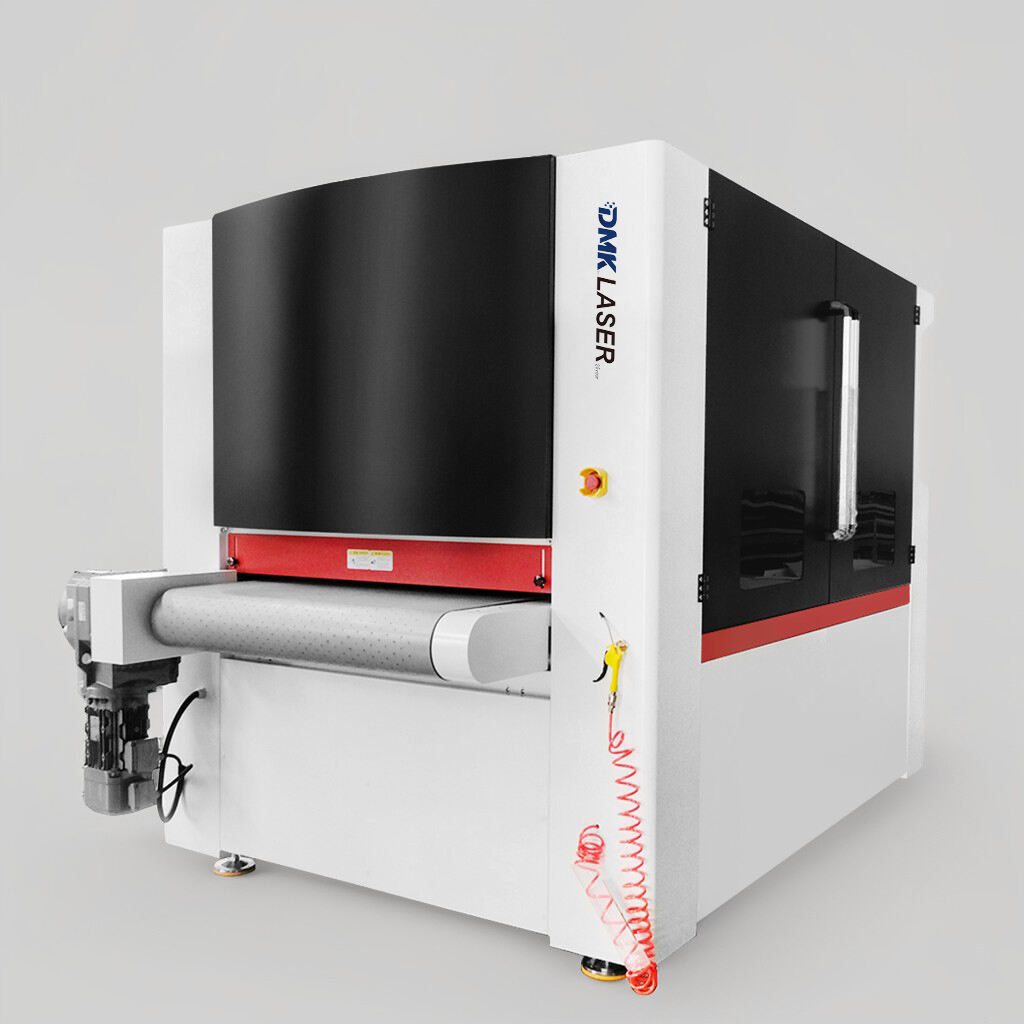

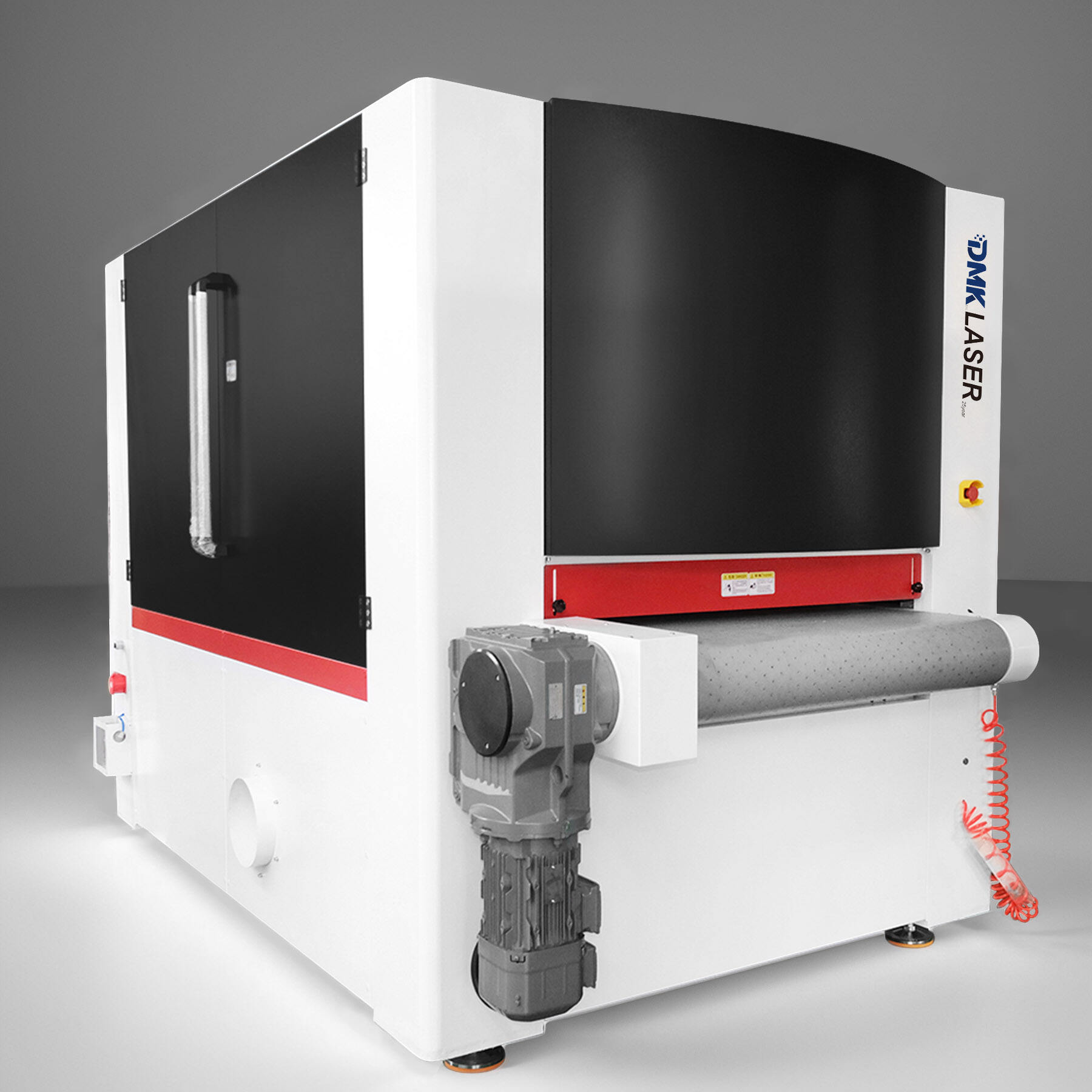

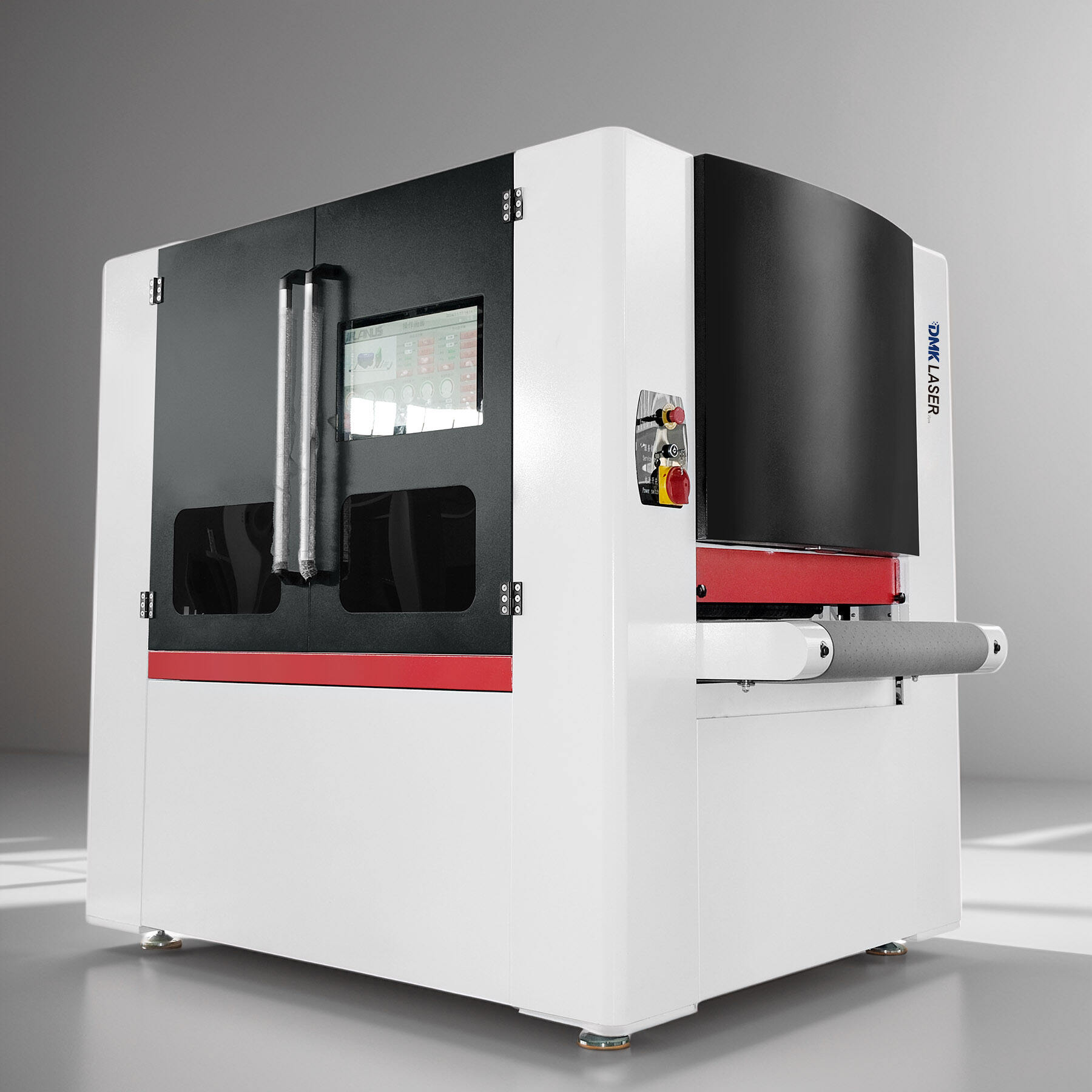

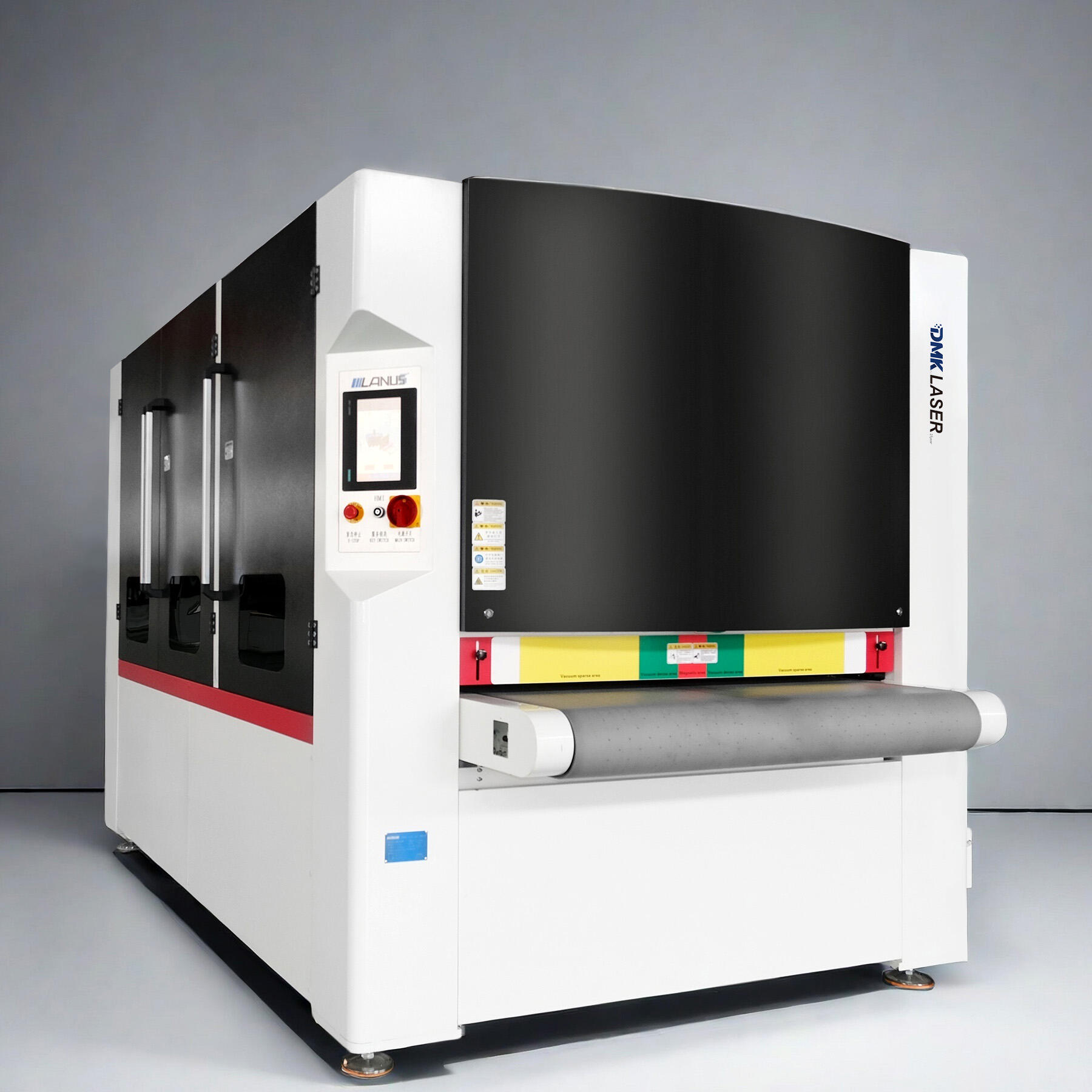

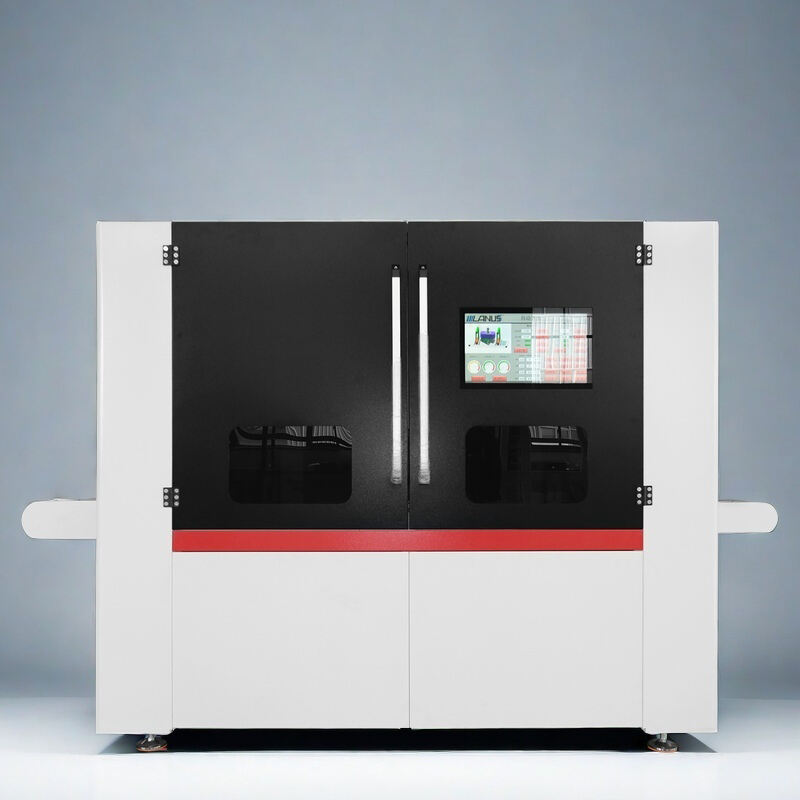

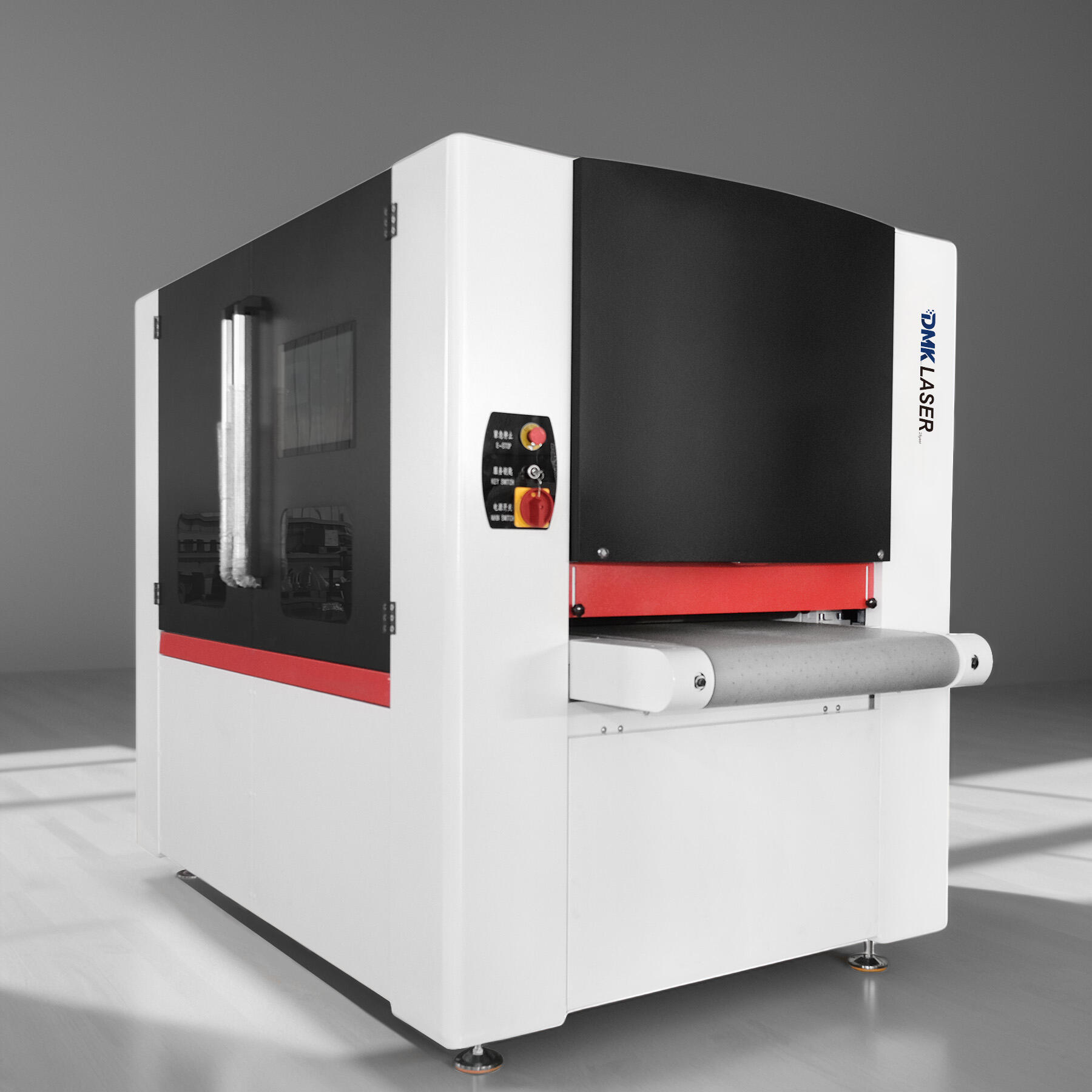

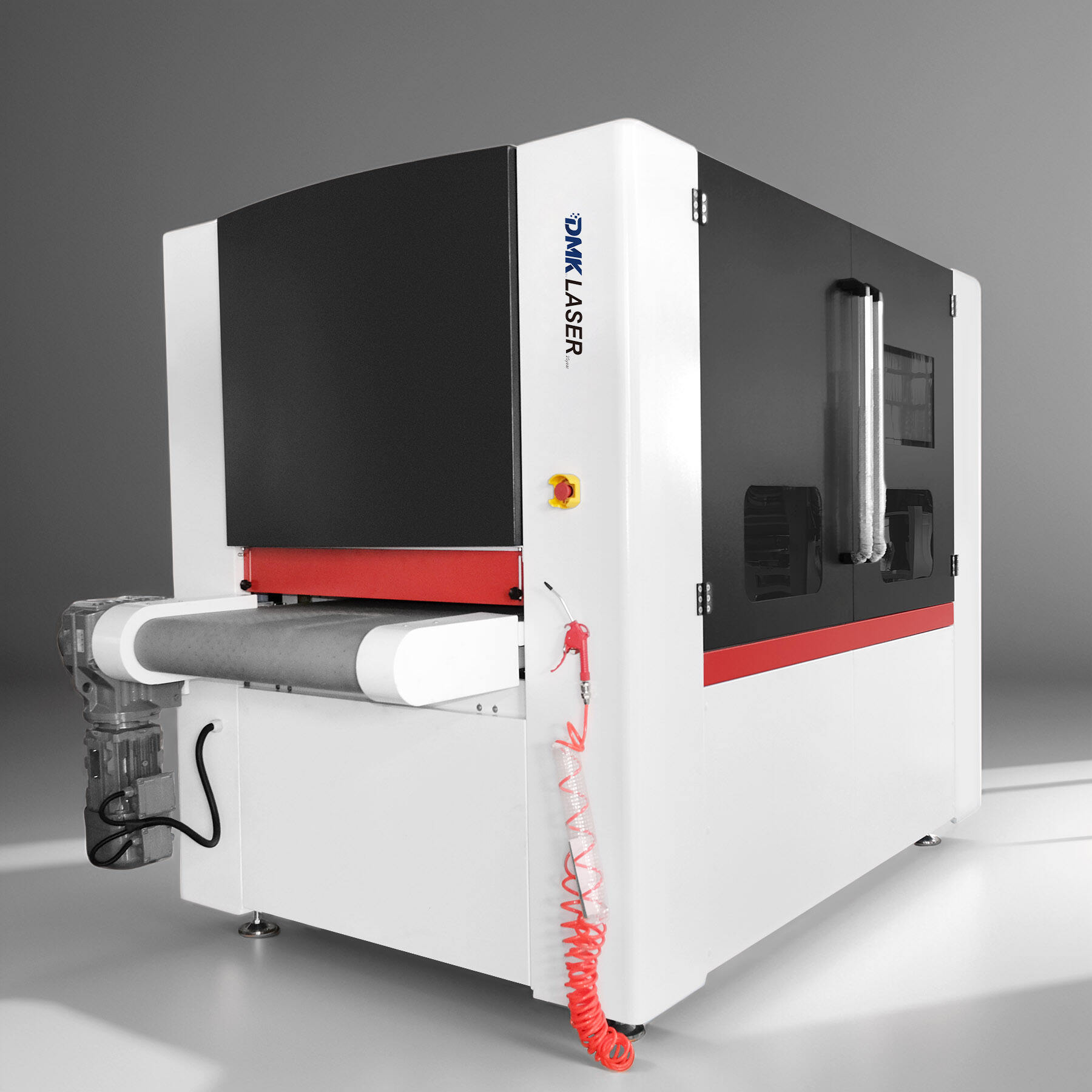

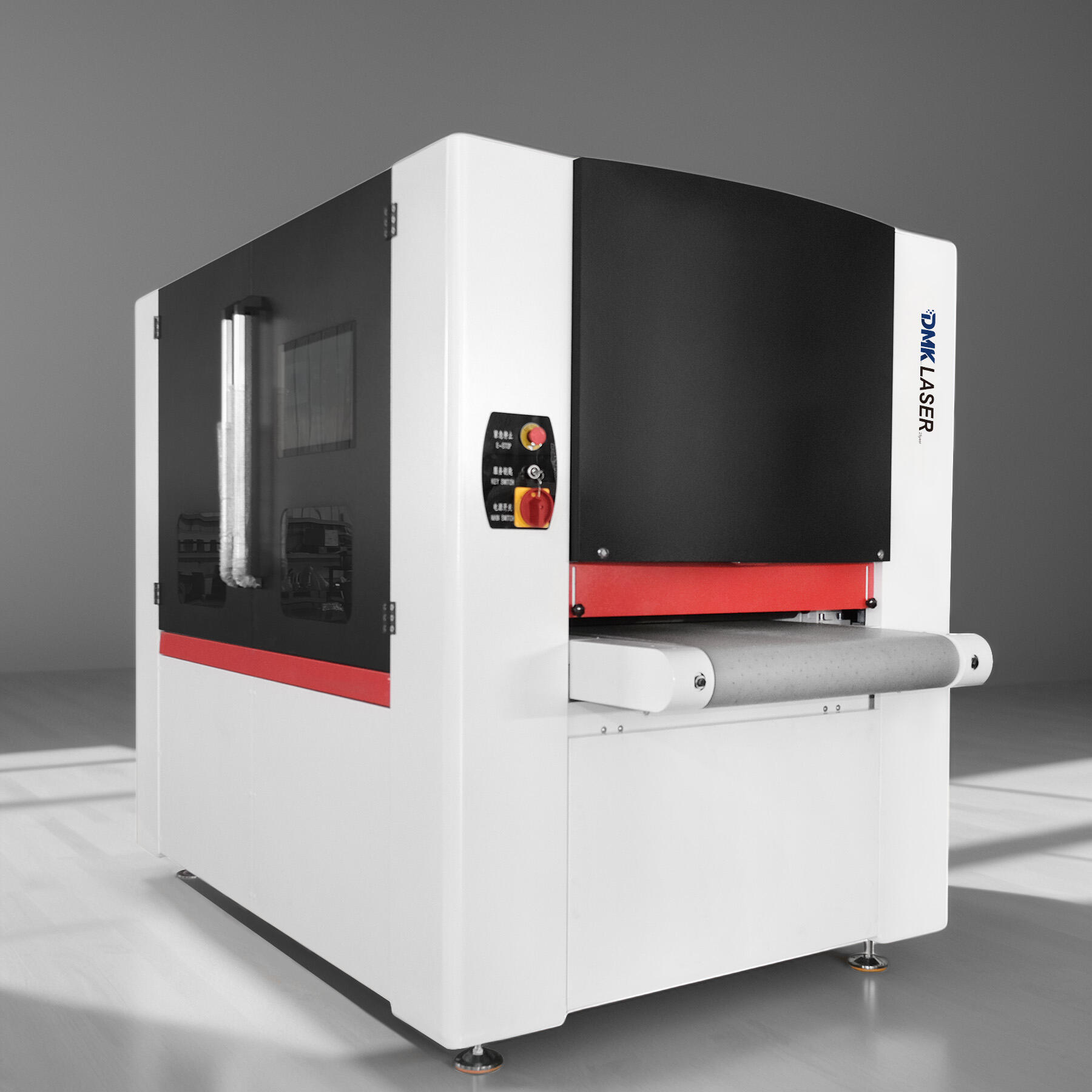

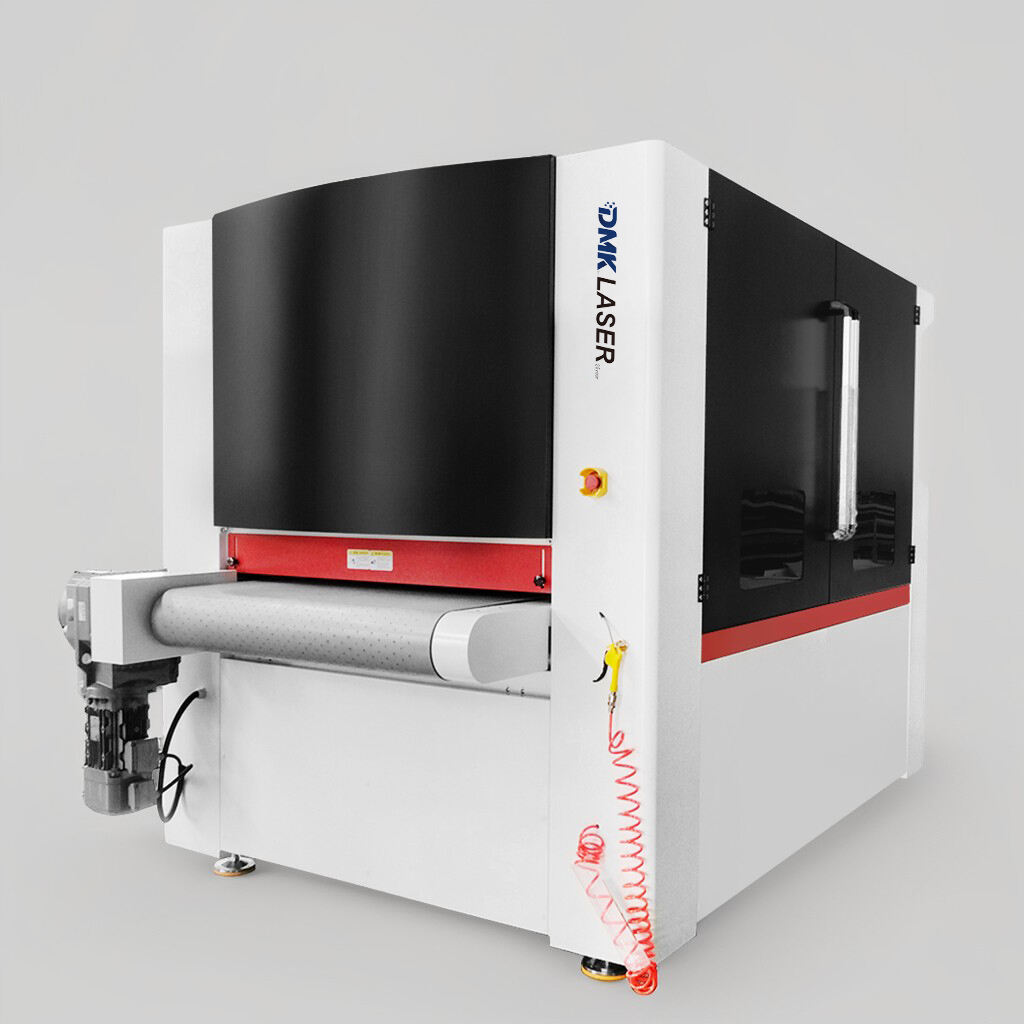

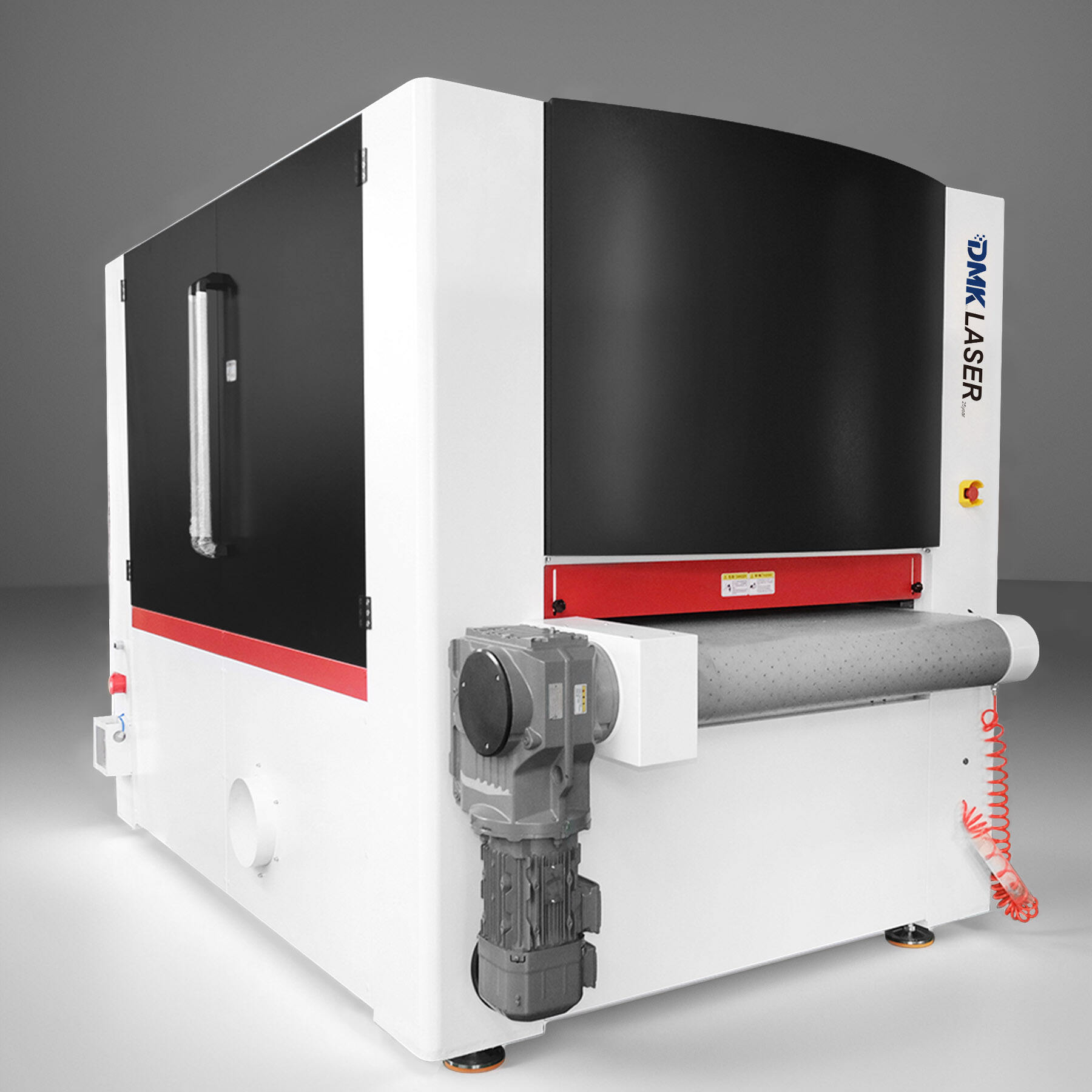

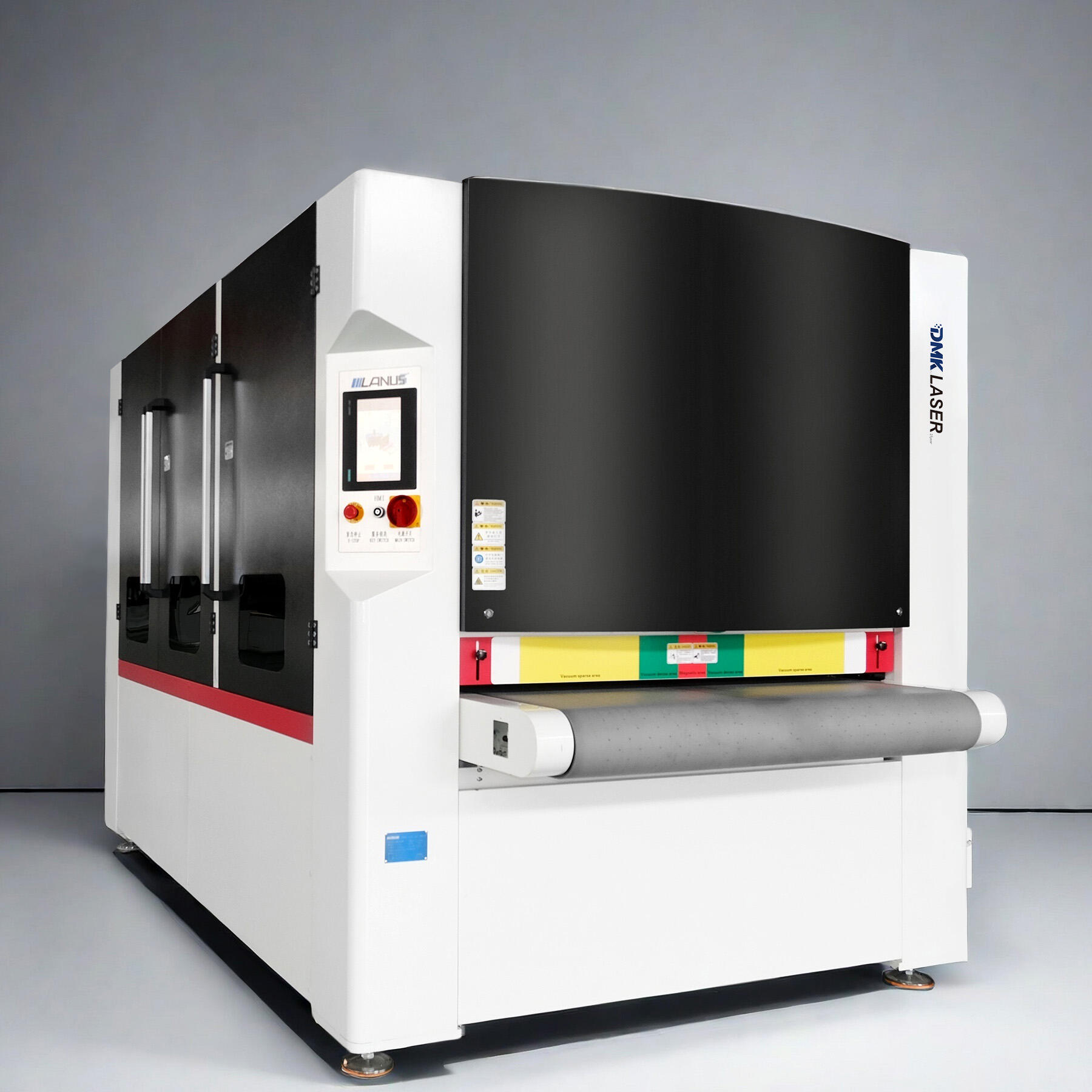

DMK Universal Roller Deburring Machine

Description

The LSP Series Universal Roller Brush Deburring Machines are engineered to meet the rigorous demands of modern sheet metal finishing. Designed for versatility and high-precision surface treatment, this series includes multiple model variants—LSPDL1350, LSPH1000, LSPL800, LSPL1000, and LSPM1000—each tailored to handle a variety of materials including carbon steel, stainless steel, aluminum, copper, titanium, and plastics.

Whether you need fine surface brushing, edge rounding, chamfering, or burr removal after cutting or stamping processes, the LSP Series offers reliable performance and consistent results.

|

|

Key Features

|

|

|

Flexible Feeding Options:

|

|

Precision-Controlled Lifting System:

|

|

|

|

Technical Specifications

| Model Options | LSPDL1350 / LSPH1000 / LSPL800 / LSPL1000 / LSPM1000 |

|---|---|

| Processing Width | 450mm–1600mm (Model-dependent) |

| Processing Thickness | 0.5mm–80mm |

| Feed Speed | 0.5–8 m/min (Variable frequency adjustable) |

| Feeding Method (Selectable) | Magnetic or Vacuum suction feeding |

| Height Adjustment | Servo-controlled, accuracy ±0.01mm |

| Control System | CNC Touchscreen (PLC) |

| Dust Collection Compatibility | Wet vacuum or pulse jet dust extractor |

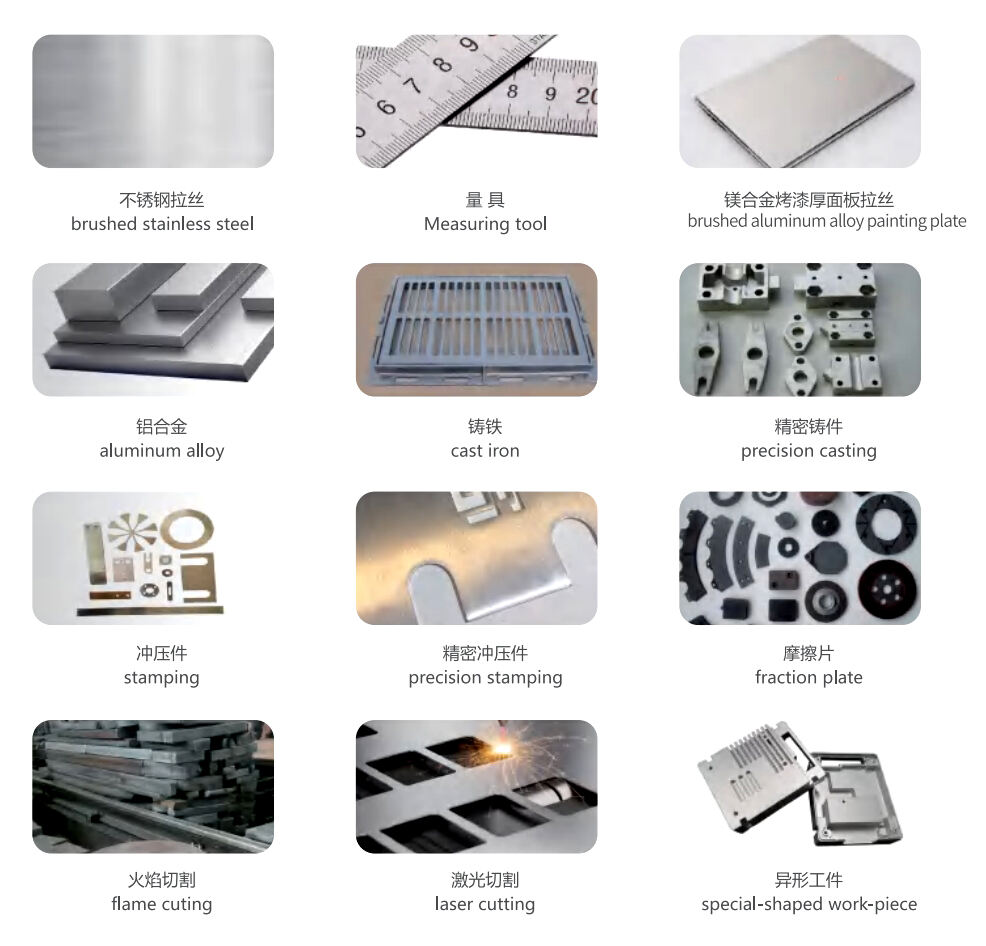

Physical picture

Applications

The LSP Series is perfect for finishing flat sheet metal and plate parts across industries:

Materials: Carbon steel, stainless steel, aluminum, copper, titanium, non-ferrous metals, and composite materials.

-

Processes Supported:

Laser cutting, plasma cutting, waterjet cutting

Shearing and stamping

Surface brushing, polishing, scratch removal

Deburring and edge rounding

Chamfering and softening sharp edges

Typical Use Cases: Automotive components, precision metal parts, aerospace panels, kitchenware, electrical enclosures, and decorative metal surfaces.

EN

EN

AR

AR CS

CS NL

NL FR

FR DE

DE IT

IT JA

JA KO

KO PL

PL PT

PT RU

RU ES

ES UK

UK TH

TH TR

TR