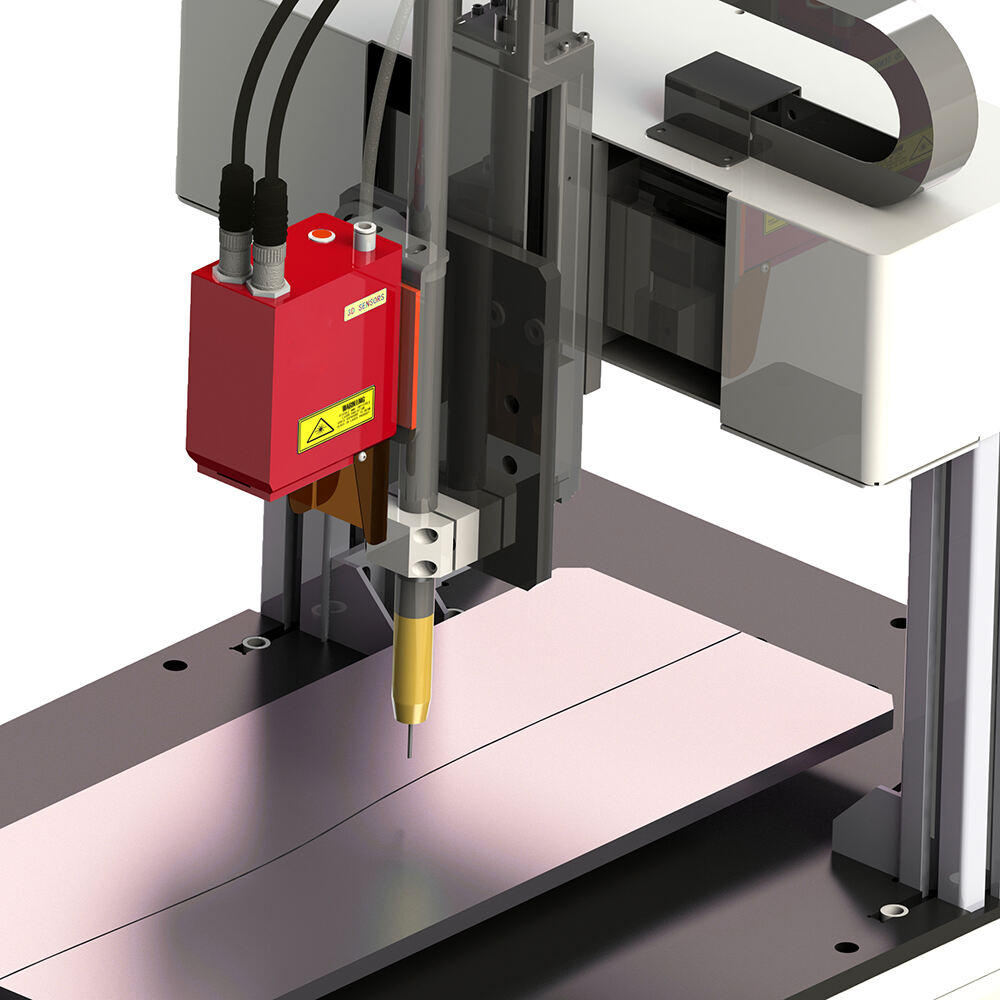

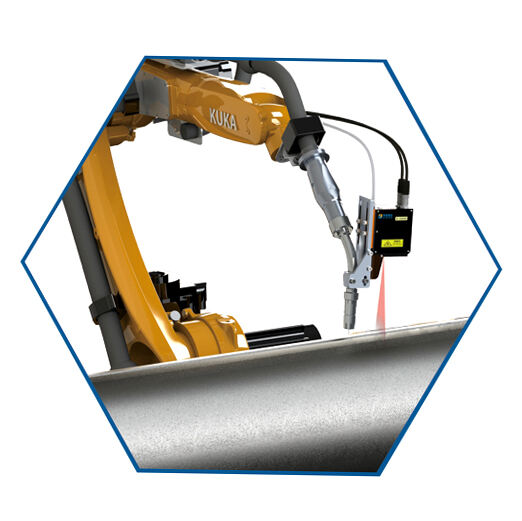

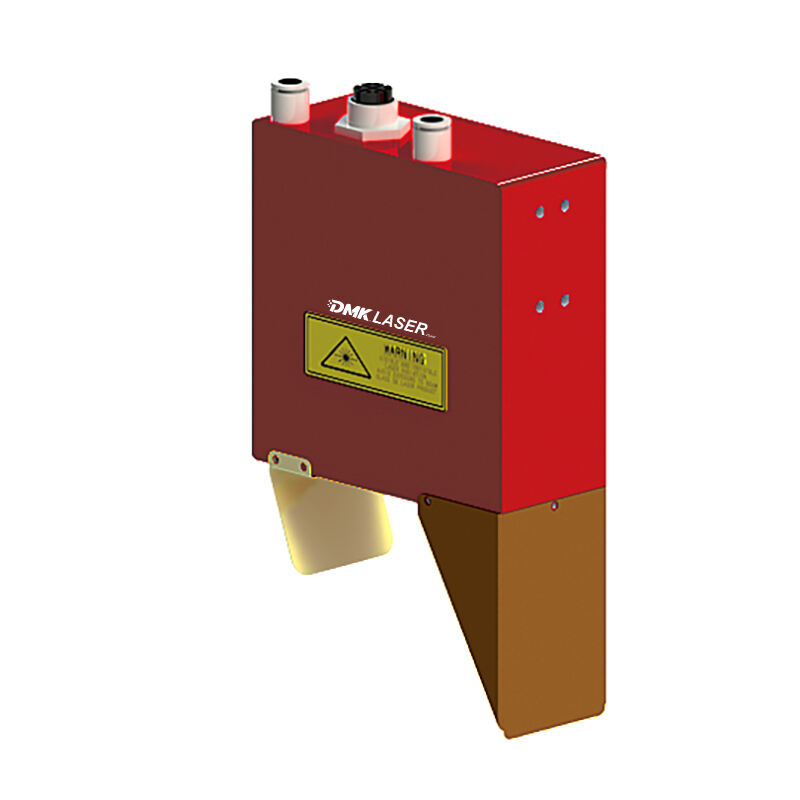

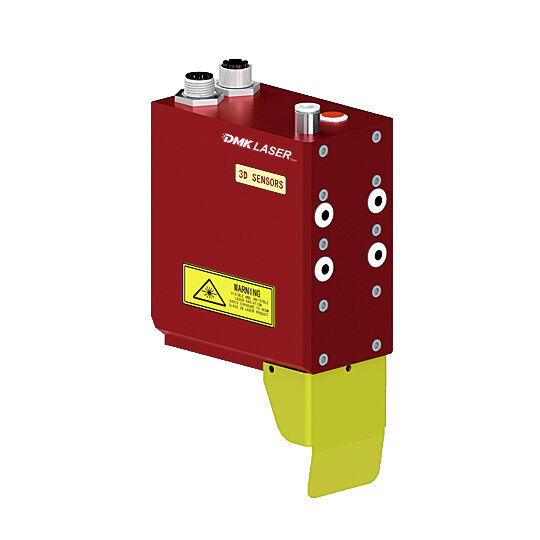

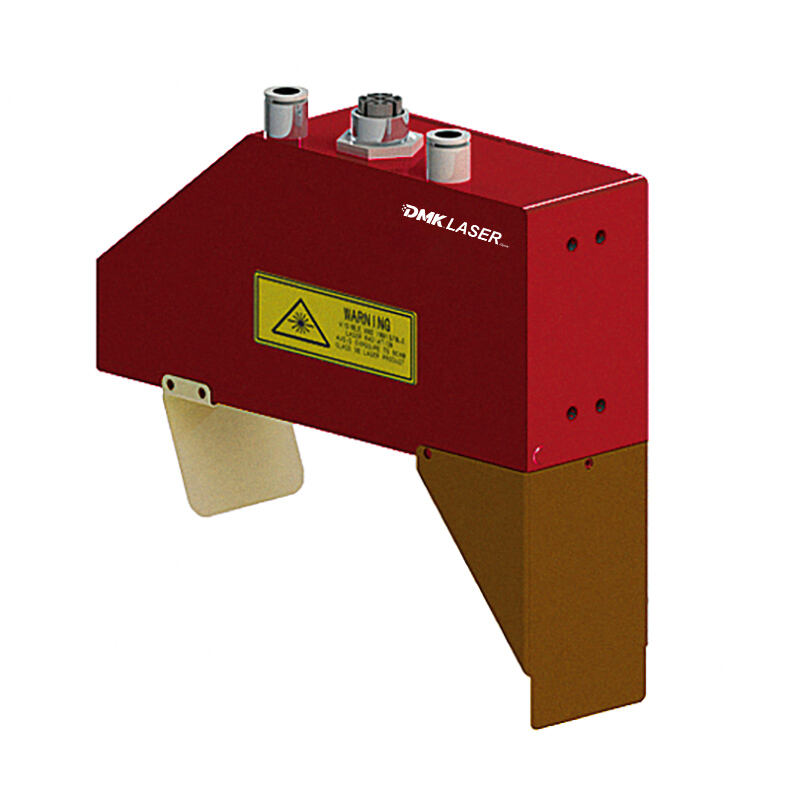

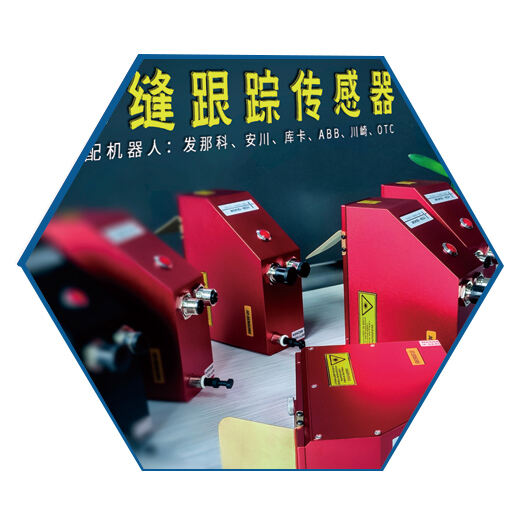

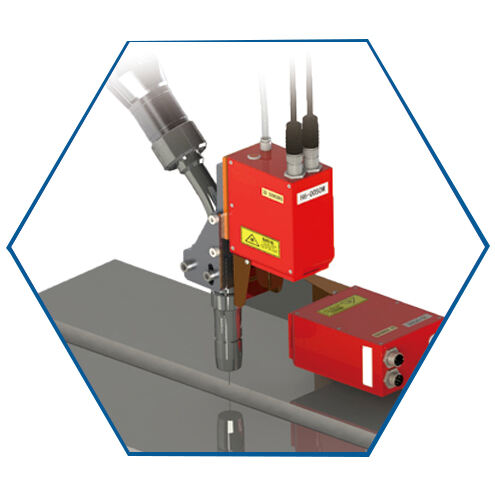

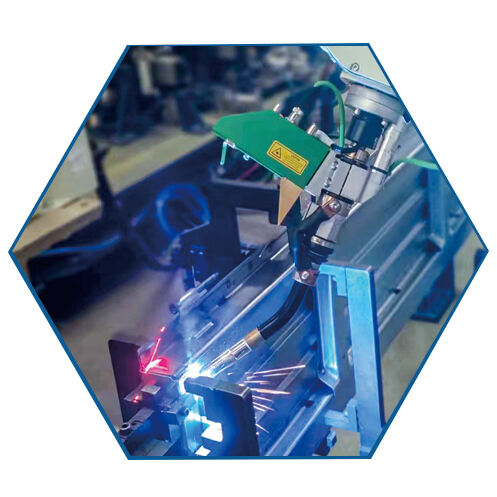

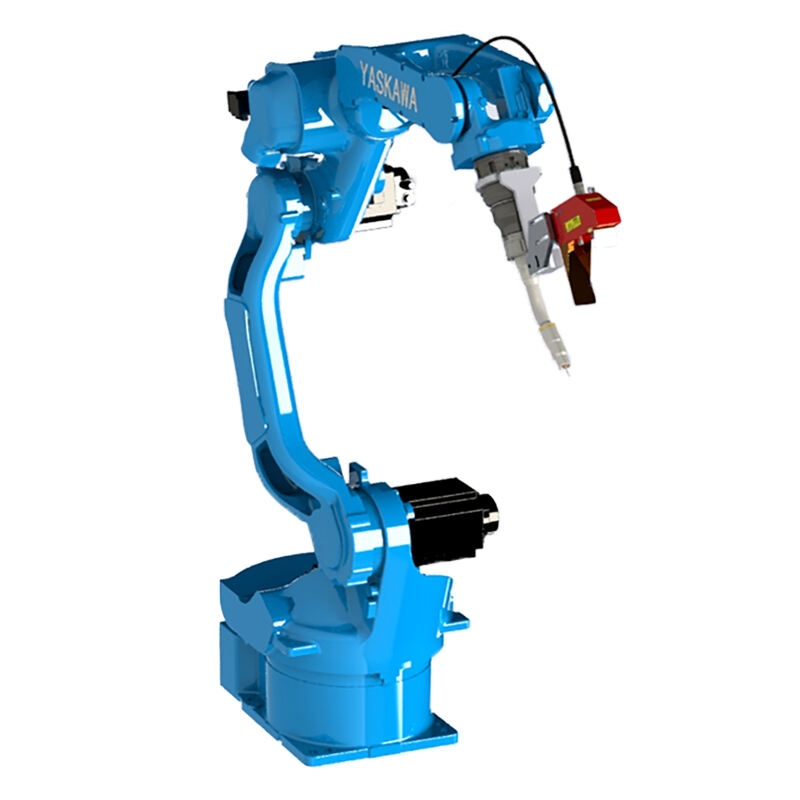

DMK 3D Seam Tracking Sensor for Robotic Welder

Principle of Operation

The Seam Tracking Sensor utilizes advanced laser triangulation technology. The laser is diffused into a line laser via a cylindrical objective lens and projected onto the surface of the target object, forming diffuse reflection. The reflected light is then captured by a CMOS camera. By analyzing changes in position and shape of the reflected light, the sensor accurately measures displacement and surface shape.

Product Description

Our Seam Tracking System uses cutting-edge sensor technology and sophisticated algorithms to enable high-precision, real-time tracking of the welding seam. This ensures that welding deviations are kept to an extremely minimal range, significantly improving the accuracy and consistency of welds.

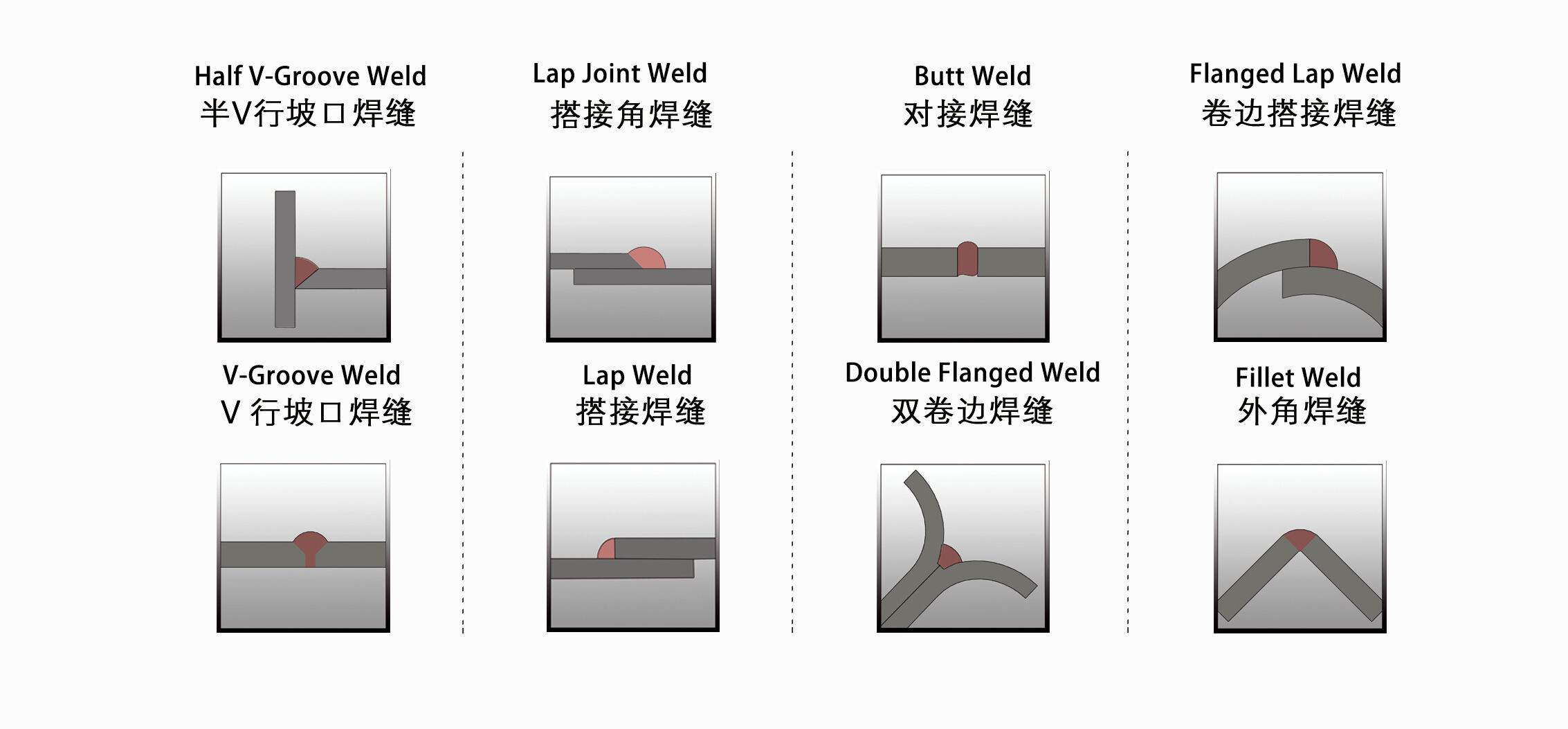

With the ability to detect and track multiple types of seams, including:

Semi-V groove welds

Butt welds

Overlap angle welds

Flanged overlap welds

V groove welds

Lap welds

Double flanged welds

External corner welds

Our system is designed to handle a wide range of measurement scenarios, from 0.011mm resolution to 1.758mm and a measuring range of 12mm to 1100mm, providing the precision and flexibility required by most industrial applications.

Key Features

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Applications

Automotive Industry: Ensures high-precision welding for automotive components.

Shipbuilding: Ideal for welding large structures requiring precise seam tracking.

Heavy Machinery Manufacturing: Enhances weld quality for industrial machinery.

Aerospace: Guarantees accurate seam tracking for aerospace components.

Fabrication and Custom Welding: Perfect for large-scale fabrication projects and specialized welding applications.

Training and Support

When purchasing our seam tracking sensor, we also offer comprehensive training services, including SDKs, tutorial videos, and remote technical support to help ensure seamless integration and operation.

EN

EN

AR

AR CS

CS NL

NL FR

FR DE

DE IT

IT JA

JA KO

KO PL

PL PT

PT RU

RU ES

ES UK

UK TH

TH TR

TR