DMK SLM Laser 500W Metal 3D Printer GT100

Product Description

The GT100 Metal 3D Printer is a high-precision metal additive manufacturing system designed for advanced R&D, medical applications, and educational training. Based on the powder bed fusion (PBF) technology, the GT100 uses laser sintering to transform digital 3D designs into dense, durable metal parts layer by layer. By integrating cutting-edge optics, material science, and digital manufacturing technology, the GT100 enables users to realize complex geometries, lightweight structures, and faster production cycles—all while reducing cost and waste.

Ideal for labs, universities, medical facilities, and enterprises seeking compact yet powerful AM solutions, the GT100 offers industry-leading 30μm spot size resolution and a fully open software and materials system to support innovation across diverse sectors.

Key Advantages

Designed for R&D and Medical Applications

Tailored to meet the precision and reliability demands of the research and healthcare sectors.Ultra-Fine Printing Precision

Industry's smallest laser spot diameter—30μm—ensures exceptional surface detail and fine feature reproduction.User-Centric Interface

Intuitive and visualized software design for easy operation, real-time monitoring, and maintenance-friendly access.High-Accuracy Forming System

Custom-developed optical path and airflow systems ensure uniform powder spreading and stable part quality.Open Platform Compatibility

Supports multiple metal powders and customizable process parameters to fit various R&D and production needs.Detailed Build Log Tracking

Automatically records build data including layer number, chamber temperature, gas levels, build cylinder position, and more—ensuring traceability and quality assurance.Safe and Stable Operation

Integrated dual-filtration system with nitrogen or argon shielding for a secure and clean working environment.

Technical Specifications

| Specification | Details |

|---|---|

| Equipment Dimensions | 980mm × 980mm × 1780mm |

| Build Volume | 110mm × 110mm × 100mm |

| Forming Accuracy | ±0.05mm |

| Powder Feeding | Powder Cylinder Feeding |

| Layer Thickness | 20–100μm |

| Laser Spot Diameter | 30μm / 50μm |

| Laser Power | 500W |

| Scanning Speed | ≤7 m/s |

| Build Speed | 5–20 cm³/h |

| Oxygen Content | ≤100 ppm |

| Gas Protection | Nitrogen (N₂) / Argon (Ar) |

| Machine Weight | 850kg |

| Power Consumption | 2.5KW |

| Software | Magics + BP, 3DXpert |

| Supported File Formats | STL / OBL / STEP |

| Compatible Materials | Stainless Steel, Tool Steel, Cobalt-Chrome Alloy, Superalloys, Titanium Alloy, Aluminum Alloy |

Application

Mold Manufacturing

Create conformal cooling channels to reduce cooling time and part deformation.

Shorter production cycles and lower manufacturing costs.

Enhanced mold productivity and precision for injection molding and die-casting industries.

|

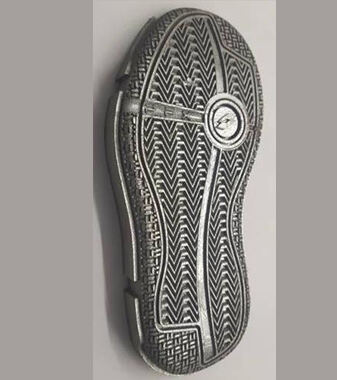

Tire Mold |

Die Casting Mold |

Shoe Mold |

Aerospace & Aviation

Manufacture complex, weight-optimized structures.

Reduce R&D lead time for new aerospace components.

Improve material utilization and minimize stress concentration for increased service life.

Engine

Automotive Industry

Enable fast prototyping and production of custom components.

Support ergonomic design and structural light-weighting.

Realize safer and more comfortable user experience through customized designs.

Car engine hood

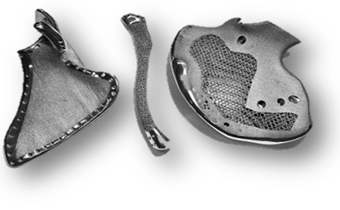

Medical and 3C Electronics

Manufacture titanium alloy medical implants and electronic parts with improved precision and reduced cost.

Allow scalable production of personalized, lightweight consumer electronics.

Address the challenge of machining hard-to-process materials like titanium with high yield and minimal waste.

|

Cobalt-Chromium Alloy |

Tantalum Alloy |

Education & Research

An ideal tool for hands-on additive manufacturing training in universities and institutes.

Supports experimental development and materials research through open process access.

|

|

Company Profile

EN

EN

AR

AR CS

CS NL

NL FR

FR DE

DE IT

IT JA

JA KO

KO PL

PL PT

PT RU

RU ES

ES UK

UK TH

TH TR

TR